Vertical Lifting Clamp Model VLC-A

Product Code: 1601

This vertical lifting clamp is designed for the efficient lifting, transport, and vertical rotation of steel plates and structures. It provides a secure gripping force, allowing metal plates to be lifted in a vertical position, making operations easier and more reliable.

Product Overview

The vertical lifting clamp model VLC-A was designed to perform all lifting, transporting, and vertical rotation tasks of steel plates and structures. It securely grips the steel plates using durable serrated jaws, ensuring safe and effective lifts. These clamps are suitable for steel plates in the vertical direction, which simplifies and makes handling more efficient, whether for lifting, transporting, or rotating.

Main Features:

- Versatility: Suitable for lifting, transporting, and rotating steel plates and structures.

- Safety First: Equipped with a safety locking mechanism to prevent slipping during lifting and lowering.

- Design Level: Easy to handle, reducing operator fatigue.

- Robust Construction: It has a high-strength welded casing for exceptional durability.

- Easy Maintenance: Maintenance is simple, with replaceable wear parts when necessary.

- Material Compatibility: Suitable for lifting steel plates with a surface hardness below 30 HRC.

Load Limits:

- Minimum Workload (MWL): 10% of the maximum nominal load.

Technical Specifications

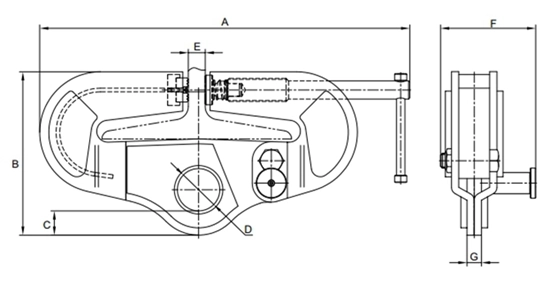

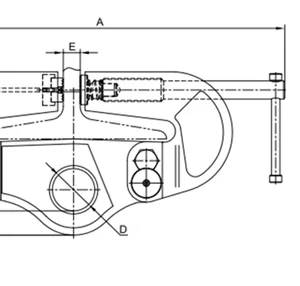

| Product Number | Capacity (t) | Test Load (kN) | Jaw Opening (mm) | T (mm) | U (mm) | V (mm) | L (mm) | Net Weight (kg) | Product Code |

|---|---|---|---|---|---|---|---|---|---|

| VLCA008 | 0.8 | 15.68 | 0-16 | 123 | 265 | 40 | 44 | 2.8 | 160100800 |

| VLCA010 | 1 | 19.6 | 0-22 | 124 | 295 | 50 | 54 | 3.6 | 160101000 |

| VLCA020 | 2 | 39.2 | 0-30 | 154 | 385 | 54 | 56 | 5.5 | 160102000 |

| VLCA030 | 3 | 58.8 | 0-40 | 180 | 400 | 60 | 72 | 10 | 160103000 |

| VLCA050 | 5 | 98 | 0-50 | 222 | 483 | 68 | 76 | 17 | 160105000 |

| VLCA080 | 8 | 156.8 | 0-60 | 265 | 535 | 65 | 90 | 26 | 160108000 |

| VLCA100 | 10 | 196 | 0-90 | 290 | 600 | 80 | 95 | 32 | 160110000 |

| VLCA120 | 12 | 235.2 | 25-90 | 408 | 700 | 80 | 113 | 48 | 160112000 |

| VLCA160 | 16 | 313.6 | 60-125 | 465 | 780 | 100 | 121 | 80 | 160116000 |

| VLCA200 | 20 | 392 | 0-90 | 563 | 933 | 100 | 140 | 149 | 160120000 |

| VLCA300 | 30 | 588 | 10-90 | 568 | 918 | 100 | 142 | 155 | 160130000 |

Related Products

- Chain Section CH-B

- Left Lever Handle LH-A

- Trole Manual PT-FA

- Heavy Duty Winches

Safe Use of Lifting Clamps

Make sure to use the vertical lifting clamp correctly and safely, following the manufacturer's guidelines. Always check the weight limits and inspect the clamp for damage before using it. Lift only materials that meet the specifications and never exceed the load capacity. Proper maintenance and regular inspections are essential to ensure long-term reliability and performance.

Safety Guide for Lifting Clamps

Mandatory:

- Store and handle lifting clamps properly to ensure safety and longevity.

- Inspect the lifting clamps and accessories before use and before storage.

- Whenever possible, fasten them firmly to the steel plate.

- Make sure the clamp is aligned directly with the center of gravity of the plate.

- Before lifting, confirm that the clamp is fully locked or tightened on the steel plate.

- Before releasing the clamp, make sure the steel plate is properly supported.

Prohibited:

- Do not use lifting clamps on hard or polished steel plates unless they are specifically designed for that.

- Do not insert shims between the steel plate and the clamp jaws.

- Do not try to lift multiple steel plates with a single clamp.

- Do not alternate between vertical and horizontal elevation unless the clamp is designed for it.

- Do not use vertical lifting clamps at an angle.

- Do not force the crane hook into the clamp eye.

Choosing the Right Lifting Clamp

Vertical lifting clamps come in a variety of capacities and designs. These clamps can use mechanisms such as levers, cams, rollers, or screws to provide a secure grip on steel plates. To select the correct lifting clamp and plan the lift, consider the following:

- Type of clamp (lever, cam, roller, or screw)

- Weight and thickness of the steel sheet

- If the use of a chain link is necessary

Note 1: Some clamp designs, particularly those with movable cam jaws that rely on springs to provide initial gripping force, have a minimum load and steel plate thickness for safe lifting. Always refer to the manufacturer's instructions (if available). In the absence of specific guidance, the load should not be less than 20% of the Safe Working Load (SWL) and the steel plate thickness should be at least 20% of the maximum thickness.

Note 2: Some lifting clamps are suitable for lifting steel plates from the horizontal position to the vertical. In these cases, the use of a chain sling is essential to provide a articulated connection between the clamp and the lifting hook.

Storage and Handling of Lifting Clamps

Never put a damaged or dirty lifting clamp back into storage. Make sure the clamp is dry, clean, and protected against corrosion.

Avoid dropping or throwing the lifting clamps to prevent damage.

Using Lifting Clamps

Make sure to handle and use the lifting clamps properly to maximize safety and effectiveness. Always follow safety procedures to ensure the best performance.

Safe Use of Lifting Clamps

- Never use lifting clamps or defective accessories.

- Unless explicitly permitted in the manufacturer's instructions, do not use clamps to lift loads less than 20% of the Safe Working Load (SWL) or with a thickness less than 20% of the maximum thickness.

- Always position the clamps correctly. Make sure the clamp is positioned directly above the load center of the plate. For long plates prone to bending, use two clamps positioned evenly around the center of gravity and, if necessary, a suspension bar. Ensure that no individual clamp exceeds its Safe Working Load.

- Whenever possible, firmly secure the clamps in the appropriate position on the board.

- Under no circumstances, place any type of shim between the plate and the jaws. Also, never try to lift multiple plates with a single clamp.

- Avoid using staples at an angle to the edge of the board or for transitions from vertical to horizontal elevation, unless the staple has been specifically designed for this type of use.

- Keep oil, grease, and similar contaminants away from the jaws, especially if they have friction material.

Inspection and Maintenance During Use

- Clean the vertical lifting clamps regularly and lubricate their moving parts at appropriate intervals, unless the supplier specifies otherwise.

- For clamps with jaws coated with friction material, make sure that the lubricant does not come into contact with the friction material.

- Regularly inspect the lifting clamps and, if any of the following defects are found, have a qualified technician thoroughly inspect the clamp:

- Wear, damage, or deformation of the fixed and movable jaws

- Opening or cracks in the structure

- Loose, worn, or bent pins and screws

- Worn friction material

- Damaged or defective locking levers

- Locked, warped, or damaged tightening thread

- Corrosion

- Illegible markings

Notice: Do not re-sharpen or re-cut the jaw teeth unless explicitly authorized by the manufacturer.

A hqlifting provides these guidelines to ensure the safe and effective use of your lifting clamps.

Reviews

There are no reviews yet.