Universal Spiral Cam Clamp SCD for Double Lifting

Code: 1609

The SCD spiral cam universal clamp for double lifting was designed for a wide range of applications, including vertical and horizontal lifting, as well as lifting for inversion or rotation and lateral (horizontal) traction. This clamp is particularly suitable for handling objects with unusual shapes, providing reliable and efficient performance.

Capacity: 1 ton to 3.2 tons

Main Features:

- Ability to move objects with unknown or irregular shapes.

- Suitable for horizontal and vertical lifting applications.

- It features a spring pressure locking mechanism for safe operation.

- Double lifting rings allow lifting/handling in any direction.

- It has enhanced security with spiral fastening and automatic locking mechanism.

- Built from forged alloy steel for durability.

- Clamp screw and swivel jaws are made of cemented/carburized alloy steel.

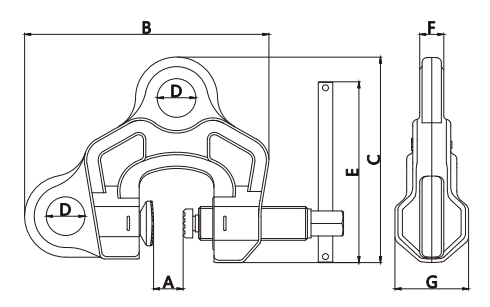

Specifications:

| Code | Capacity (t) | Claw Opening (A) | Dimensions (mm) | Net Weight (kg) | Product Code |

|---|---|---|---|---|---|

| SCD010 | 1 | 0-40 | 203 x 170 x 32 | 4.3 | 160901000 |

| SCD020 | 2 | 0-40 | 226 x 190 x 36 | 8.2 | 160902000 |

| SCD032 | 3.2 | 5-40 | 250 x 205 x 45 | 10 | 160903200 |

Related Products:

- Chain Paddle Type CH-B

- LH-A Type Lever Handle

- Trole Manual Type PT-FA

- Half-door with Reinforced Hasp

Safe Use of Lifting Clamps

Always:

- Store and handle the lifting clamps carefully.

- Inspect the clamps and accessories before use and after storage.

- Position the clamps as deeply as possible into the steel plate.

- Make sure the clamps are positioned directly above the center of gravity of the load.

- Make sure the clamps are fully locked or tightened on the steel plate before lifting.

- Make sure the steel plate is properly supported before attempting to release the clamps.

Never:

- Use lifting clamps on hardened or polished steel plates, unless they have been specifically designed for this purpose.

- Place shims between the steel plate and the clamp jaws.

- Try to lift more than one steel plate at a time with the clamps.

- Alternate between vertical and horizontal elevation, unless the clamps have been specifically designed for this purpose.

- Do not apply side load on vertical lifting clamps.

- Force a lifting hook on the clamp lifting rings.

Selecionando o Grampo de Elevação Correto

Lifting clamps come in different capacities and designs, using mechanisms such as lever, cam, roller, or screw action to provide friction on the steel plate. When selecting a clamp, consider the following:

- The type of clamp (lever, cam, roller, or screw action).

- The capacity and thickness of the steel plate.

- If a set of lifting chain is necessary.

Note 1: Generally, the load and the thickness of the steel plate should not be less than 20% of the Safe Working Load (SWL) and the maximum nominal thickness, respectively. Always consult the manufacturer's instructions (if available).

Note 2: In these cases, it is essential to use a lifting chain to create a flexible connection between the clamp and the hook, avoiding unnecessary weight on the clamp, which can cause it to come loose.

## Improving the Storage and Handling of Lifting Clamps

Never put damaged or dirty lifting clamps back in place. They must be kept dry, clean, and with proper anti-corrosion measures. Avoid dropping or improperly discarding lifting clamps, as this can cause damage.

Safe Use of Lifting Clamps

- Never use defective lifting clamps or any related accessories.

- Unless otherwise specified by the manufacturer, do not lift loads less than 20% of the Safe Working Load (SWL) or with thickness less than 20% of the maximum thickness.

- Make sure the clamp is positioned correctly, above the load center of the plate.

- For long plates prone to bending, use two clamps positioned symmetrically in relation to the center of gravity, along with a lifting bar. Care must be taken to ensure that no clamp exceeds its SWL.

- Posicione o grampo completamente na chapa.

- Em nenhuma hipótese devem ser colocados calços.

Reviews

There are no reviews yet.