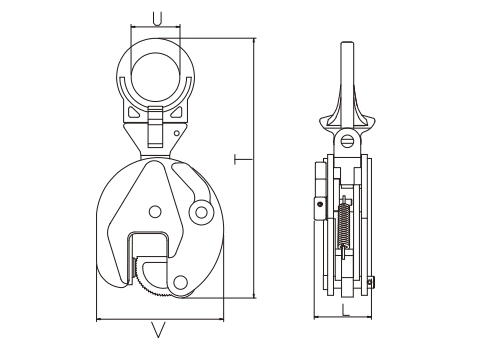

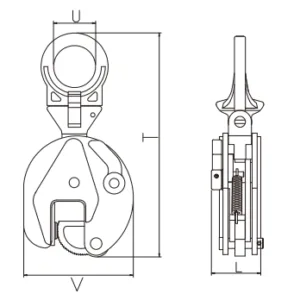

Universal Lifting Clamp Model ULC-A

Model No: 1602

The universal lifting clamp, also known as the universal steel plate clamp, is specially designed to lift, transport, and rotate various types of steel plates and structures vertically, from any position.

Main Features:

- Suitable for lifting, transporting, and rotating steel plates and structures, both vertically and horizontally.

- The minimum allowable workload is 10% of the maximum workload.

- Equipped with an articulated shackle for lifting, providing flexibility at various angles.

- The articulated shackle ensures a secure fastening, even under lateral loads of up to 90°.

- For elevations above 45°, please refer to the load reduction guidelines below.

- It is possible to lift longer steel plates using a two-leg chain sling together with two clamps.

- This way, the use of a lifting beam is not necessary.

- This clamp has a safety mechanism that prevents the load from slipping during lifting and lowering.

- The clamp remains securely locked in both the open and closed positions.

- Light, easy to maintain, and robust and durable construction.

- Suitable only for lifting steel plates with a surface hardness below 30 Rockwell C (HRC).

Specifications:

| Part number | Capacity (t) | Test load (kN) | Jaw opening (mm) | Dimensions (mm) | Net weight (kg) | Product code |

|---|---|---|---|---|---|---|

| ULCA008 | 0.8 | 15.68 | 0-15 | 205 x 30 x 105 | 2 | 160200800 |

| ULCA010 | 1 | 19.6 | 0-20 | 300 x 50 x 145 | 5 | 160201000 |

| ULCA020 | 2 | 39.2 | 0-25 | 385 x 68 x 175 | 8 | 160202000 |

| ULCA032 | 3.2 | 62.72 | 0-30 | 430 x 75 x 215 | 15 | 160203200 |

| ULCA050 | 5 | 98 | 0-50 | 500 x 68 x 232 | 23 | 160205000 |

| ULCA080 | 8 | 156.8 | 0-45 | 600 x 88 x 290 | 37 | 160208000 |

| ULCA120 | 12 | 235.2 | 50-90 | 700 x 90 x 420 | 50 | 160212000 |

| ULCA160 | 16 | 313.6 | 60-100 | 710 x 100 x 445 | 65 | 160216000 |

| ULCA200 | 20 | 392 | 0-80 | 948 x 100 x 563 | 160 | 160220000 |

| ULCA300 | 30 | 588 | 10-90 | 944 x 100 x 568 | 167 | 160230000 |

Related Products:

- Chain Paddle Model CH-B

- Guincho de Alavanca Manual Modelo LH-A

- Carro Manual PT-FA

- Polias Reforçadas

Utilização Segura dos Grampos de Elevação:

Certifique-se de que os grampos estão posicionados corretamente e inspecione-os em busca de sinais de desgaste ou danos. Siga as diretrizes de Carga Limite de Trabalho (CLT) máxima do fabricante para garantir uma operação segura e evitar exceder a capacidade de elevação recomendada.

Essential Guide to Lifting Clamps

Mandatory:

- Store and handle the lifting clamps with care.

- Inspecione os grampos de elevação e seus acessórios antes e depois do uso.

- Make sure the clamp is securely fastened to the steel plate and, whenever possible, insert it completely.

- Check if the clamp is positioned directly above the center of gravity of the load.

- Before lifting, confirm that the clamp is fully locked or attached to the steel plate.

- Always exercise extreme caution to ensure that the steel plate is properly supported before releasing the clamp.

Prohibited:

- Do not use lifting clamps on hardened or polished steel plates unless they are specifically designed for such.

- Do not insert shims between the steel plate and the clamp jaws.

- Do not try to lift multiple steel plates at once with a clamp.

- Do not change the load orientation between vertical and horizontal unless the clamp is specifically designed for that purpose.

- Do not apply load to vertical lifting clamps in an inclined manner.

- Do not force the fitting of the lifting equipment hook into the clamp eye.

Choosing the Right Lifting Clamp

Lifting clamps come in different capacities and designs. They may feature levers, cam mechanisms, rollers, or screws to ensure a secure grip on the steel plate. When selecting a lifting clamp and planning a lift, consider the following factors:

- Clamp type: lever, cam, roller, or screw.

- Load capacity and steel sheet thickness.

- If a lifting chain is necessary.

Note 1: Some clamp designs, particularly those with a cam mechanism (where the initial clamping force is provided by a spring), have a minimum load and minimum steel plate thickness they can safely lift. Always refer to the manufacturer's instructions. In the absence of specific guidelines, ensure that the load is not less than 20% of the SWL and that the steel plate thickness is at least 20% of the maximum steel plate thickness.

Note 2: Some types of lifting clamps are designed to lift steel plates from horizontal to vertical. In these cases, it is essential to use a lifting chain to facilitate an articulated connection between the clamp and the lifting hook. The use of a lifting chain is highly recommended to prevent the weight of the hook from being applied to the clamp, which could result in the accidental release of the clamp.

Storage and Handling of Lifting Clamps

Never put damaged or dirty lifting clamps back in place. Always clean and thoroughly inspect them before storing to ensure their functionality and safety.

Lifting Clamps: Maintenance and Safety Guide

Maintenance and General Care

The lifting clamps must be stored in a dry and clean environment to prevent corrosion. Avoid dropping or throwing the clamps, as this can damage them.

Safety in the Use of Lifting Clamps

- Do not use damaged or defective lifting clamps or accessories.

- Unless otherwise indicated by the manufacturer, clamps must not be used to lift loads less than 20% of the Safe Working Load (SWL) nor steel plates with a thickness less than 20% of the maximum thickness.

- Position the clamps correctly on the load. Position them at the center of gravity of the steel plate. For long steel plates prone to bending, use two clamps, positioned evenly around the center of gravity, together with a lifting bar. Make sure the weight supported by a single clamp does not exceed its Safe Working Load.

- The clamps must bite into the steel plate as deeply as possible.

- Never place spacers between the steel plate and the jaws and do not try to lift multiple steel plates with a single clamp.

- Unless the clamps are specifically designed for this purpose, do not use them at an angle to the edge of the steel plate or for lifting between vertical and horizontal positions.

- Keep oil, grease, and other contaminants away from the jaws, especially those with friction fastening materials, to ensure safe and efficient operation.

Inspection and Maintenance in Use

- The lifting clamps must be cleaned regularly and the moving parts must be lubricated as needed, unless otherwise specified by the manufacturer.

- In pliers with smooth jaws coated with friction material, make sure that the lubricant does not come into contact with this material.

- Regularly inspect the lifting clamps. If any of the following defects are detected, request a thorough inspection of the clamp by a qualified professional:

- Wear, damage, or deformation on the fixed or movable jaws.

- Cracks or structural expansion.

- Pinos e parafusos soltos, desgastados ou tortos.

- Material de fixação por fricção desgastado.

- Alavanca de travamento danificada ou inoperante.

- Rosca de aperto excessivamente apertada, torta ou danificada.

- Corrosão.

- Marcações ilegíveis.

Attention: Não rebarbe ou ressole os dentes das mandíbulas, a menos que expressamente autorizado pelo fabricante.

Reviews

There are no reviews yet.