Talha Manual de Corrente 1 Ton with 5 Meters of Lifting and Trolley for Industrial Structures

A Talha Manual Antispark H-Lift, also known as talha manual explosion-proof, is specifically designed for use in potentially explosive environments. Its manufacture complies with the ATEX 2014/34/EU and Machinery 2006/42/EC directives, ensuring safety and compliance.

Main Features:

- Compliance with Standards: Complies with the standards of the ATEX 2014/34/EU and Machinery 2006/42/EC directives.

- Epoxy Powder Coating: Offers enhanced protection against corrosion.

- Galvanized Load Current: Guarantees resistance and durability.

- Copper-Coated Steering Wheel and Hook: Increases protection against sparks.

- Corrosion-Resistant Internal Components: Ensures reliable and long-lasting operation in harsh environments.

- Fasteners and Fastening Elements in Stainless Steel: Provides excellent corrosion resistance.

- Identification Plate and Bronze Rivets: Increases durability and wear resistance.

- Overload Protection (Optional): Available for greater security.

Specifications:

| Item Number | Nominal Load (t) | Standard Lifting Height (m) | Test Load (kN) | Force Required to Lift the Nominal Load (N) | Número de Ramais da Corrente | Chain Specification | Dimensions (mm) | Net Weight (kg) | Additional Weight per Meter (kg) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

| LHEP050 | 0.5 | 1.5 | 7.35 | 256 | 1 | 5X15 | 143 x 90.5 x 118 | 23.5 | 5.5 | 120600500 |

| LHEP075 | 0.75 | 1.5 | 11.0 | 290 | 1 | 6X18 | 152 x 91.5 x 132 | 26 | 6.9 | 120600750 |

| LHEP100 | 1 | 1.5 | 14.7 | 300 | 1 | 6X18 | 157 x 94 x 140 | 26 | 7.9 | 120601000 |

| LHEP150 | 1.5 | 1.5 | 22.1 | 350 | 1 | 7X21 | 178 x 104 x 145 | 31 | 10.9 | 120601500 |

| LHEP300 | 3 | 1.5 | 44.1 | 390 | 1 | 10X30 | 206 x 118 x 199 | 37 | 20.2 | 120603000 |

| LHEP600 | 6 | 1.5 | 88.2 | 400 | 2 | 10X30 | 206 x 118 x 230 | 46 | 35 | 120606000 |

| LHEP900 | 9 | 1.5 | 132.3 | 410 | 3 | 10X30 | 206 x 118 x 342 | 55 | 50 | 120609000 |

Safe Use of the Manual Hoist:

To ensure optimal safety and performance, it is essential to maintain and operate the Talha Manual Spark-Proof H-Lift Correctly, following the manufacturer's guidelines. Always check the condition of the hoist before use, especially in explosive or hazardous environments.

Related Products:

- Tirfor / Steel Cable Winch

- Clamp for BC Beam

- Universal Lifting Clamp ULC

- Talha Chain Manual CH-B

The H-Lift Spark-Proof Manual Hoist, reliable and robust, is the ideal choice for your critical safety applications.

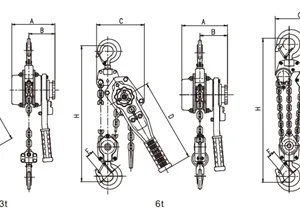

Lever Handle – Manual Lifting Solutions

The lever hoist, also known as a lever winch (Tirfor type) or ratchet hoist, is a versatile mechanical lifting tool designed to lift and move heavy loads. It is particularly useful when manual lifting is the only option or when electrical/hydraulic solutions are not practical.

The lever hoist is operated by a lever that activates a ratchet mechanism with a pawl, allowing precise control of lifting and lowering the load. The lever is connected to a chain or steel cable that winds onto a drum inside the hoist body. When pulling the lever, the ratchet engages, turning the drum. This movement, in turn, raises or lowers the chain or cable.

Typical Applications of the Lever Hoist

Lever hoists are widely used in industries such as construction, manufacturing, and mining, where heavy lifting and material handling are required. Their compact design, durability, and ease of operation make them suitable for use by a single person. Lever hoists come in various sizes and lifting capacities, so selecting the right model depends on the weight of the load you need to handle.

How to Operate a Lever Hoist

After securing the top hook and the load, follow these steps:

- Lifting the Load:

Move the lever to the lift position (indicated as 'up') and repeatedly operate the lever. - Lowering the Load:

Move the lever to the lowering position (indicated as ‘down’) and repeatedly operate the lever to lower the load. - Adjusting the Chain Length:

Place the lever in the neutral position (center position). Now the chain can be pulled in both directions to quickly position the lower hook as needed.

Suspension and Fixation of the Lever Hoist

To suspend a lever chain hoist, connect the upper hook to a shackle, beam clamp, trolley, or other secure support. The lower hook can be attached directly to the load (if it has a suitable accessory) or through lifting slings and shackles. For pulling or tensioning tasks, the upper and lower hooks are often secured using lifting slings.

Important Safety Guidelines

Always:

- Store and handle the lever hoist properly.

- Inspect the hoist and accessories before use and before storage.

- Make sure the support is firmly positioned on the hook latch, avoiding side load.

- Test the brake function.

- Check if the lower hook reaches its lowest point and if the chain does not hit the stop.

- Follow safe lifting practices and the equipment safety instructions.

Never:

- Never expose the lever hoist to chemicals (especially acids) without consulting the supplier, as this may cause damage to the equipment.

- Replace the charging cable with a longer one without the guidance of the manufacturer or a specialist.

- Never extend the lever or force the hoist.

- Play, drop, or drag the lever hoist.

- Let oil or grease come into contact with the brake.

- Expose the hoist to harsh environments (such as water, steam, etc.).

How to Choose the Right Lever Hoist

Lever hoists are available in different capacities, with link chain or roller chain. When selecting a lever hoist, consider the following:

- Current Type: Link chain or roller chain.

- Nominal Load and Lifting Range: Make sure the hoist is suitable for the load weight and lifting height.

Lever hoists are designed for versatile use and can be used for lifting and pulling operations in any direction. For high-risk environments or exposure to elements, hazardous materials (such as acids), or extreme conditions, always consult a manufacturer or specialist for proper guidance.

Hqlifting offers a variety of high-quality lever hoists that make it easier to handle various lifting and pulling tasks.

Storage and Handling of Manual Hoists

- Do not put damaged manual hoists back into stock. Make sure they are dry, clean, and protected against corrosion.

- When storing manual hoists, hang them by the hook, keeping the chain suspended, off the floor.

- Never drop, throw, or drag manual hoists on the floor.

- Do not perform galvanization or any other electroplating process on the chains or load-bearing components without prior approval from the supplier.

Installation and Commissioning

- Follow the specific installation instructions and the general guidelines provided by the supplier.

- Test the manual hoist to ensure its proper operation and the effectiveness of the brake.

- Make sure the chain is not twisted and moves freely.

- Check if the lower hook reaches the lowest desired position and if the chain does not reach the end of the stroke.

Uso Seguro de Talhas Manuais

- Never perform lifting operations without having a full understanding of the equipment and slinging procedures.

- Do not use manual hoists or damaged or defective accessories.

- Check the sling arrangement, make sure the manual hoist is securely fastened and that the chain is not twisted. Avoid using the load chain as a sling.

- Before starting, make sure the load can move freely and that the landing area is properly prepared.

- Lift the load slightly off the ground, pause and check the manual hoist, the slinging method, and the safety.

- Do not use a pipe to extend the operating lever or force the hoist.

- Prevent the load from swinging out of control.

- Stay away from the load and protect your fingers, feet, etc., when lowering it.

Inspection and Operational Maintenance

- Follow the specific maintenance instructions from the supplier, especially regarding lubrication and cleaning of the load chain. Make sure the brake is operating correctly and without oil.

- Nunca substitua por uma corrente de carga mais longa sem consultar o fornecedor.

- Regularly inspect the manual hoist and, if any of the following faults are found, refer it to a qualified person for a complete inspection:

- Wear or damage on the hooks, accessories, or loose chain end stop.

- Worn, bent, notched, stretched, cracked, corroded, twisted chain or with locked links.

- Load slipping or failing to lift.

- Damage to the hoist housing or the operating lever.

- Marcações ilegíveis.

Grade 80 Load Chain

Features:

- Short pitch chain link for lifting purposes, in accordance with EN 818-7 and made of fine tolerance hoist chain, Grade T, Type T.

- Normally used in manually operated hoists or slower electric hoists, in non-abrasive environments.

- The Grade 80 load chain is designed for heavy-duty applications and is known for its high strength and durability.

Usage Guidelines:

- The Grade 80 chain of the hoist must not be exposed to acidic solutions or vapors.

- Make sure the chain passes through the sprockets smoothly and without twists.

- To extend the lifespan, lubricate the hoist chain, especially at the link connections.

- Keep the hoist chain clean to prevent the buildup of dirt or sand.

Product Specifications:

- Finish: Óxido preto ou galvanizado eletricamente.

Available Sizes and Specifications:

| Part Number | Size (mm) | Step (mm) | Width (mm) | Length in 11 Steps (mm) | WLL (kN) | Test Force (kN) | Minimum Breaking Load (kN) | Mass (kg/m) | Product Code |

|---|---|---|---|---|---|---|---|---|---|

| G8H0412 | 4 | 12 | 4.8 | 13.6 | 0.5 | 1.32 | 12.6 | 0.35 | 501020412 |

| G8H0515 | 5 | 15 | 6.0 | 17.0 | 0.8 | 1.65 | 19.6 | 0.55 | 501020515 |

| G8H0618 | 6 | 18 | 7.2 | 20.4 | 1.1 | 1.98 | 28.3 | 0.78 | 501020618 |

| G8H0721 | 7 | 21 | 8.4 | 23.8 | 1.5 | 2.31 | 38.5 | 1.06 | 501020721 |

| G8H0824 | 8 | 24 | 9.6 | 27.2 | 2 | 2.64 | 50.3 | N/A | N/A |

Product Details

Product 1:

- Model: G8H0927

- ID: 501020824

- Dimensions (L x W x H): 80.4 x 1.38 x 10.8 cm

- Weight: 9 kg

- Maximum Load: 27 kg

- Height Adjustment Range: 30.6 cm

- Course: 297 mm

- Speed: 2.5 mm/s

- Energy consumption: 63.6 watts

- Voltage: 102 volts

- Capacity: 1.78 liters

Product 2:

- Model: G8H1030

- ID: 501020927

- Dimensions (L x W x H): 10.8 x 1.78 x 12.0 cm

- Weight: 10 kg

- Maximum Load: 30 kg

- Height Adjustment Range: 13.4 in

- Course: 330 mm

- Speed: 3.2 mm/s

- Energy consumption: 78.5 watts

- Voltage: 126 volts

- Capacity: 2.2 liters

Product 3:

- Model: G8H1030

- ID: 501021030

- Dimensions (L x W x H): 12.0 x 2.2 x 10.8 cm

- Weight: 10 kg

- Maximum Load: 30 kg

- Height Adjustment Range: 13.4 in

- Course: 330 mm

- Speed: 3.2 mm/s

- Energy consumption: 78.5 watts

- Voltage: 126 volts

- Capacity: 2.2 liters

Reviews

There are no reviews yet.