Spark-Proof Chain Bucket Model CH-EP

Item No.: 1106

The H-Lift CH-EP spark-proof chain hoist, or explosion-proof chain hoist, was designed for use in areas with explosion risk. Manufactured in compliance with the requirements of the ATEX Directive 2014/34/EU and the Machinery Directive 2006/42/EC, this hoist offers a safe and reliable solution for challenging applications.

Descrição

Safe Operation of the Chain Hoist

- Grade 80 Load Chain

The spark-proof or explosion-proof chain hoist model CH-EP is an efficient mechanism for lifting or lowering heavy loads with minimal effort. The operation of the hoist is based on the winding of the chain on internal gears, which facilitates the lifting of objects attached to the hook. This system significantly reduces the force required to lift loads of up to 30,000 kg.

Furthermore, in most cases, these chain hoists do not rely on electricity, making them ideal for use in remote areas or where access to power is limited. They are essential tools for machine installation, equipment maintenance, work at heights, and applications in confined spaces, such as automotive workshops, factories, laboratories, and power plants.

Main features:

- Em conformidade com a ATEX Directive 2014/34/EU e a Machinery Directive 2006/42/EC.

- Powder epoxy paint for greater durability.

- Galvanized load chain and manual chain in stainless steel, both corrosion resistant.

- Manual chain wheel and hooks with copper coating for rust protection.

- Corrosion-resistant internal components to ensure long-lasting performance.

- Stainless steel fasteners and clips for greater durability.

- Identification plate and bronze rivets for a robust and professional appearance.

- Optional overload protection for increased safety.

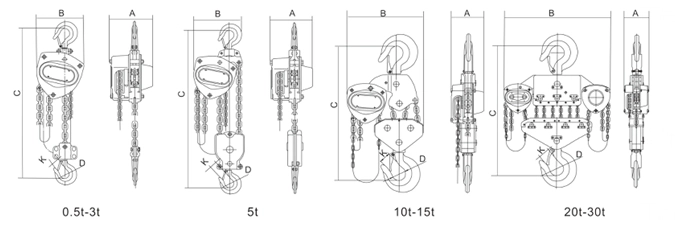

Especificações do Produto

| Item No. | Capacity (t) | Standard Lifting Height (m) | Test Load (kN) | Required Traction Force with Nominal Load (N) | Número de Ramais da Corrente | Corrente de Carga (mm) | Dimensions (mm) | Weight (kg) | Additional Weight per Meter (kg) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

| CHEP005 | 0,5 | 2,5 | 7,35 | 240 | 1 | 5X15 | 132 x 148 x 345 | 23 | 9,3 | 110600500 |

| CHEP010 | 1 | 2,5 | 14,7 | 250 | 1 | 6X18 | 151 x 172 x 376 | 26 | 12,2 | 110601000 |

| CHEP015 | 1,5 | 2,5 | 22,05 | 265 | 1 | 7.1X21 | 173 x 196 x 442 | 29,5 | 16,5 | 110601500 |

| CHEP020 | 2 | 2,5 | 29,4 | 310 | 1 | 8X24 | 175 x 210 x 470 | 34 | 19,5 | 110602000 |

| CHEP030 | 3 | 3 | 44,1 | 372 | 1 | 10X30 | 205 x 255 x 530 | 37,5 | 32 | 110603000 |

| CHEP050 | 5 | 3 | 73,5 | 380 | 2 | 10X30 | 189 x 280 x 630 | 41 | 43 | 110605000 |

| CHEP100 | 10 | 3 | 147 | 385 | 4 | 10X30 | 189 x 385 x 780 | 50 | 80,7 | 110610000 |

| CHEP150 | 15 | 3 | 183,75 | 385 | 6 | 10X30 | 242 x 405 x 920 | 80 | 140 | 110615000 |

| CHEP200 | 20 | 3 | 245 | 390 x 2 | 8 | 10X30 | 226 x 640 x 980 | 80 | 180 | 110620000 |

| CHEP300 | 30 | 3 | 367,5 | 390 x 2 | 12 | 10X30 | 454 x 705 x 1280 | 80 | 350 | 110630000 |

* Nota: Para os modelos CHEP200 e CHEP300, os valores indicam a força de tração necessária *em cada* corrente.

Related Products

- Lever Handle Model LH-A

- Beam Clamp Model BC

- Grampo de Elevação Universal Modelo ULC

- Carro de ट्रांसlação Simples Modelo PT-CA

Uso Seguro da Talha de Corrente

Ao usar a talha de corrente H-Lift, certifique-se de seguir todos os procedimentos de segurança para evitar acidentes ou danos. A realização de inspeções e manutenções regulares é fundamental para garantir a operação segura e eficiente do equipamento em diversos ambientes industriais.

Avisos de Segurança Importantes

Mandatory:

- Armazenar e manusear talhas manuais corretamente.

- Inspecionar a talha manual e seus acessórios antes de cada uso e antes do armazenamento.

- Para suspensão do gancho superior, certifique-se de que o gancho esteja equipado com uma trava de segurança; se não houver trava de segurança, utilize um cabo de aço fino ou similar para fixar o gancho, e certifique-se de que o suporte esteja totalmente encaixado na base do gancho.

- Para suspensão com trole, verifique se o trole foi ajustado corretamente à largura da viga.

- Certifique-se de que o gancho inferior possa atingir seu ponto mais baixo sem estender totalmente a corrente.

- Siga os códigos de prática de elevação segura e observe as instruções de uso seguro do equipamento.

Prohibited:

- Export the manual hoist to chemicals, especially acids, without consulting the supplier.

- Replace the chain with a longer one without the supplier's approval.

- Apply excessive force to operate the hoist.

- Drop, throw, or drag the manual hoist.

- Allow oil or grease to come into contact with the brake.

- Expose the manual hoist directly to adverse weather conditions, water, steam, etc., without consulting the supplier.

Selecting the Appropriate Hoist

Manual hoists are available in a variety of capacities and suspension types. When selecting a hoist for your lifting needs, consider the following:

- Type of suspension: Hook, trolley, etc.

- Capacity, load capacity, and lifting range: Make sure the hoist is suitable for your specific lifting needs.

- Only vertical lift: Manual hoists are specifically designed for vertical lifting.

- If the hoist is used in a high-risk environment, such as exposure to adverse weather conditions, water, steam, hazardous substances like acids and alkalis, or extreme temperatures, be sure to consult the supplier for expert advice.

Storage and Handling of Manual Hoists

- Storage Guidelines: Never store a damaged hoist. Make sure the hoist is clean, dry, and protected against corrosion.

- The hoist must be stored hanging by the top hook, keeping the chain off the ground. The chain can be coiled to facilitate storage.

- Non-portable hoists stored outdoors must be covered to prevent corrosion.

- Never drop, throw, or drag the manual hoist.

- Do not galvanize or apply any other surface treatment process to the chain or load-bearing components without the express approval of the supplier.

Installation and Testing

- Follow all specific installation instructions provided by the supplier, as well as the general requirements listed.

- Test the hoist to ensure it operates smoothly and evenly and that the brakes work reliably. Make sure the chain moves freely and is not twisted.

- The lower hook must reach the lowest required position without fully extending the chain.

Safe Operation of Manual Hoists

- Make sure that lifting is performed only after a complete understanding of the equipment operating procedures and the correct lifting methods.

- Never use defective hoists, slings, or accessories and do not use the manual hoist as a sling.

- Before each lift, be sure to inspect the lifting system to ensure that the hoist is installed stably and securely and confirm that the chain is not twisted.

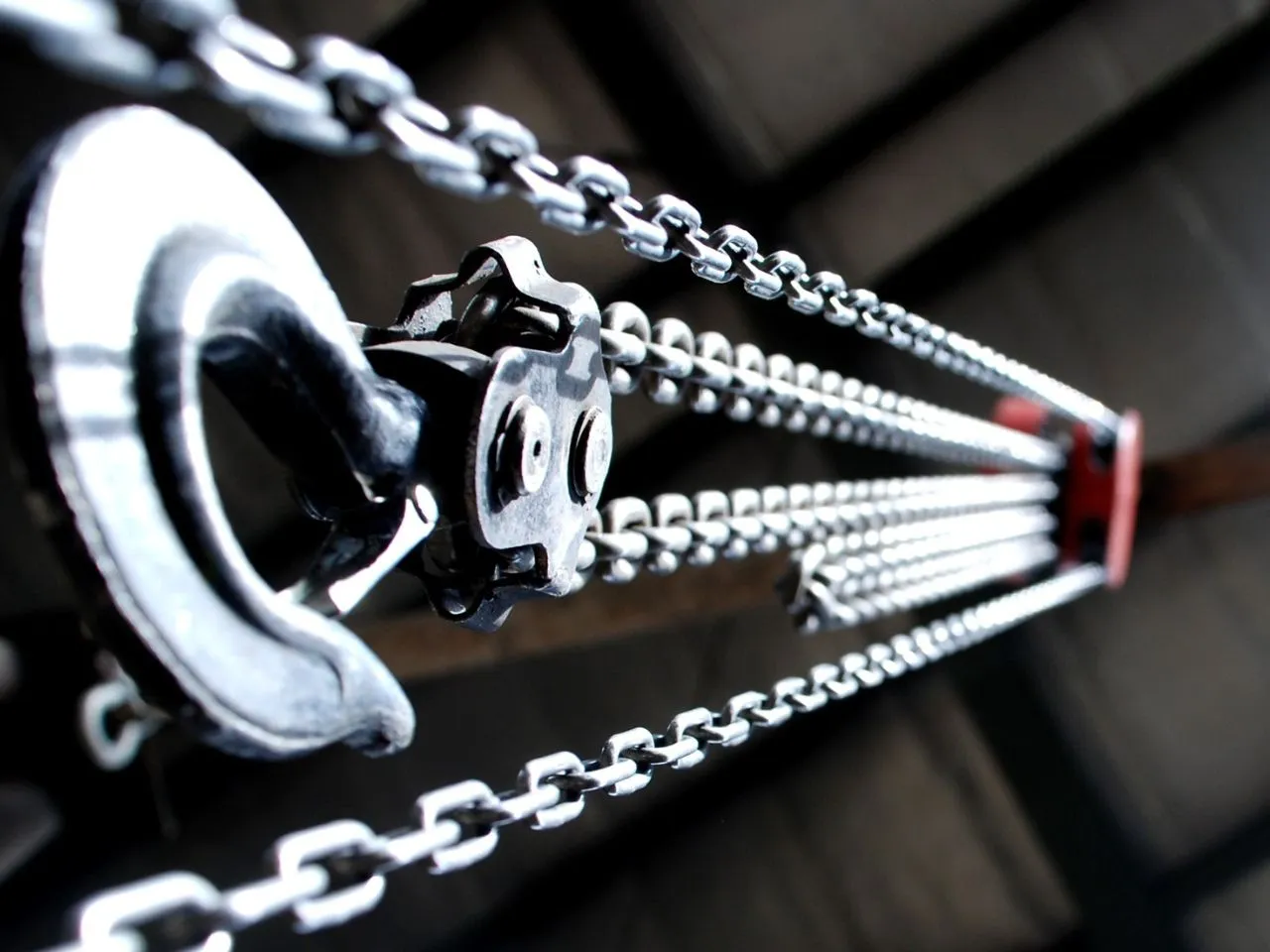

Multibranch Chain Sprocket

Before performing any operation with a multi-branch chain hoist, make sure that the load can move freely and that the landing area is properly prepared.

- Elevação Inicial: Levante a carga ligeiramente, faça uma pausa para inspecionar a talha, as técnicas de amarração e a integridade dos componentes relacionados.

- Trajeto de Movimentação: Confirme se o trajeto de movimentação está livre de obstruções, garantindo que não haja engates inesperados do gancho ou colisões. Sempre siga as normas de segurança do local para movimentação de cargas suspensas.

- Segurança: Ao abaixar a carga, mantenha todas as partes do corpo, como dedos das mãos e dos pés, longe da carga.

Inspection and Maintenance During Use

Siga todas as instruções de manutenção fornecidas pelo fornecedor. Os principais pontos a serem considerados incluem:

- Lubrificação: Mantenha a corrente de carga lubrificada e certifique-se de que o freio esteja funcionando corretamente. O freio deve estar livre de óleo, graxa e outros contaminantes.

- Inspeções Regulares: Realize inspeções de rotina para detectar quaisquer defeitos. Se alguma das seguintes condições for encontrada, consulte uma pessoa qualificada para uma inspeção completa:

- Desgaste ou danos no carrinho, ganchos e acessórios

- Âncoras soltas danificadas ou deformadas

- Desgaste, dobras, entalhes, alongamento, corrosão, torção ou corrente que não se move livremente

- Carga escorregando ou que não eleva

- Damaged hoist housing

- Illegible markings

Grade 80 Load Chain

A corrente de carga Grau 80 é projetada para aplicações de elevação e está em conformidade com a norma EN 818-7. É comumente usada em talhas manuais e elétricas, especialmente em ambientes não abrasivos.

Main Features:

- High Resistance: Made of alloy steel, the Grade 80 load chain offers high strength and durability, making it ideal for heavy lifting and material handling operations.

- Lubrificação: To maximize lifespan, the hoist chain must be lubricated regularly, especially in the contact areas between the links.

- State: The chain must be kept clean to prevent dust or sand from affecting the movement of the chain.

- Contact with Acids: A corrente da talha nunca deve ser usada em soluções ácidas ou exposta diretamente a vapores ácidos.

- Fluid Operation: Ensure that the chain is guided smoothly and free of twists when passing over the sprockets.

Grade 80 Load Chain Specifications (EN818-7)

| Material Number | Diameter (mm) | Chain Pitch (mm) | Minimum Internal Diameter (mm) | Maximum Outer Diameter (mm) | Length of 11 x Pitch (mm) | WLL (T) | Test Force (kN) | Minimum Breaking Load (kN) | Mass (kg/m) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

| G8H0412 | 4 | 12 | 4.8 | 13.6 | 132 | 0.5 | 12.6 | 20.1 | 0.35 | 501020412 |

| G8H0515 | 5 | 15 | 6.0 | 17.0 | 165 | 0.8 | 19.6 | 31.4 | 0.55 | 501020515 |

| G8H0618 | 6 | 18 | 7.2 | 20.4 | 198 | 1.1 | 28.3 | 45.2 | 0.78 | 501020618 |

| G8H0721 | 7 | 21 | 8.4 | 23.8 | 231 | 1.5 | 38.5 | 61.6 | 1.06 | 501020721 |

| G8H0824 | 8 | 24 | 9.6 | 27.2 | 264 | 2 | 50.3 | 80.4 | 1.38 | 501020824 |

| G8H0927 | 9 | 27 | 10.8 | 30.6 | 297 | 2.5 | 63.6 | 102 | 1.78 | 501020927 |

| G8H1030 | 10 | 30 | 12.0 | 34.0 | 330 | 3.2 | 78.5 | 126 | 2.2 | 501021030 |

Surface Finish:

- Black oxidized or zinc-plated finish.

This Grade 80 lifting chain is ideal for lifting applications that require a high-strength chain, ensuring safety and durability in various lifting operations. Be sure to follow maintenance procedures to ensure maximum lifespan and optimal performance.

Brand Name: hqlifting

Product Details

- Brand Name: hqlifting

- Item Dimensions:

- Width: 550 pixels

- Height: 52,16% wide

- Right margin: 0 pixels (important)

- Bottom margin: 15 pixels, except for the last item in the series

- Product Features:

- Robust and durable construction

- Elegant design that integrates perfectly with the environment

- Made with premium materials to ensure long-lasting performance

- Designed with precision engineering to meet all necessary standards

- Ideal for personal and professional environments

- Additional Information:

- Design focused on details to ensure a premium user experience

- Helps enhance the aesthetics of any area

- Easy to integrate with existing equipment or decor

- Great value for money, without compromising quality

Reviews

There are no reviews yet.