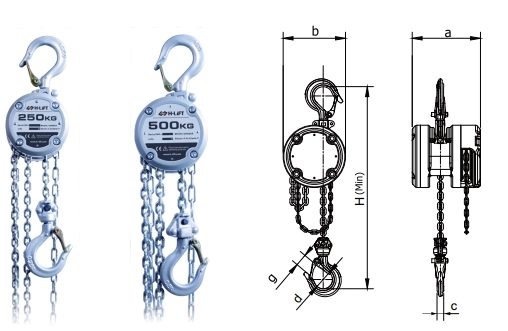

Talha Manual Mini CH-S

Item number: 1108

A CH-S model manual mini hoist is a compact and efficient lifting solution, suitable for various applications. Designed for industrial environments and domestic applications, it offers reliable lifting, pulling, and securing capabilities. Ideal for use in factories, power plants, laboratories, and garages.

Main Features:

- Compact and Light: Designed for confined spaces and working at heights.

- Durable Housing: Made with a lightweight aluminum alloy for maximum portability.

- Strong and Reliable Hooks: It has forged and heat-treated load hooks to ensure durability under heavy loads.

- Overload Indication Markings: It has overload indication markings on the upper and lower hooks for greater safety.

- Safety Mechanisms: Uses a dual-ratchet automatic brake system to prevent accidental falls during lifting.

- High-Quality Current: It has galvanized charging current and manual current for greater resistance to wear and corrosion.

- Tested: Each hoist is tested with 1.5 times the Working Load Limit (WLL).

- Compliance: Meets international safety and quality standards, including EN13157, ASME B30.16, AS1418.2, and SANS 1594.

Specifications:

| Item number | W.L.L. (lbs) | Standard Lifting Height (m) | Test Load (kN) | Force Required to Lift the Nominal Load (N) | Número de Ramais da Corrente | Charge Current | Dimensions (mm) | Net Weight (kg) | Additional Weight per Meter (kg) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

| CHS0250 | 250 | 2.5 | 3.68 | 144 | 1 | 3.2×9 | 92x84x11x32x21 | 225 | 2.6 | 0.4 |

| CHS0500 | 500 | 3.0 | 7.35 | 183 | 1 | 4.3×12 | 106x102x13x35x23 | 260 | 4.8 | 0.9 |

Note: Hoists with other lifting heights are also available.

Related Products:

- Left Lever Handle LH-A

- Beam Clamp BC

- Universal Lifting Clamp ULC

- Simple Trolley PT-CA

Safe Use of the Manual Hoist

To maximize safety and extend the lifespan of the hoist, ensure the correct operation and regular maintenance of the manual mini hoist.

Manual Hoist Safety Guide

Mandatory:

- Store and handle the manual hoists correctly.

- Inspect the hoist and its accessories before each use and during storage.

- When suspending from the top, always use hooks with safety locks. If there is no safety lock, secure the hook using an anti-loosening method and make sure the support is firmly positioned in the hook slot.

- When suspending with a trolley, make sure the trolley is properly adjusted to the width of the beam.

- Make sure the lower hook reaches the desired lowest point without fully extending the chain.

- Follow the safety standards for slings and comply with the equipment instruction manual.

Prohibited:

- Do not expose the manual hoist to chemicals, especially acids, without consulting the supplier.

- Do not replace the load chain with a longer chain without consulting the supplier.

- Forcing the hoist to operate by applying excessive force.

- It is strictly forbidden to drop, throw, or drag the manual hoist.

- Avoid contact of oil or grease with the brakes.

- Do not expose the manual hoist directly to environments such as water jets, steam, or other environmental factors without consulting the supplier.

Choosing the Right Hoist

Manual hoists come in a variety of capacities and suspension types. To choose the right hoist for the job, consider the following:

- Type of suspension (hook, trolley, etc.)

- Hoist capacity, duty class, and lifting range.

- Manual hoists are specifically designed for vertical lifting.

- If the hoist is used in high-risk areas, exposed to adverse environmental conditions (such as water, steam, or chemicals), or subject to extreme temperatures, be sure to consult the supplier.

Storing and Handling Manual Hoists

- Do not put damaged hoists back into storage. Make sure they are dry, clean, and properly protected against corrosion.

- Store the hoists suspended from the top, ensuring that the chain does not touch the floor. The chain can be coiled to facilitate storage.

- Non-portable hoists stored outdoors must be covered and protected against corrosion.

- Never drop, throw, or drag the hoist on the floor.

- Do not galvanize or apply any galvanizing process to the chain or load-bearing components without the express approval of the supplier.

Installation and Commissioning

- Follow any specific installation instructions provided by the supplier, as well as the general requirements.

- Test the hoist to ensure its proper operation and check the effectiveness of the brakes.

- Make sure the chain is not twisted and moves freely.

- Confirm if the lower hook can reach the desired lowest point without fully extending the chain.

Using the Manual Hoist Safely

- Do not attempt lifting operations unless you fully understand how to use the equipment and the correct lifting techniques.

- Never use defective hoists, slings, or accessories and avoid using the manual hoist as a sling.

- Inspect the sling equipment to ensure that the hoist is securely connected and check that the chain is not twisted, especially in hoists with multiple chains.

- Before starting the lift, confirm that the load can move freely and ensure that the landing area is properly prepared.

- Slightly raise the load to check the integrity of the hoist and the sling equipment.

- Make sure the travel path is free of obstacles and maintain a clear line of sight to avoid unforeseen events.

Inspection and Maintenance in Service

Be sure to follow any specific maintenance guidelines provided by the manufacturer, paying special attention to keep the lifting chain well lubricated and check that the brake is working properly. Make sure the brake is free of oil, grease, or similar substances. Always consult the supplier before replacing the lifting chain with a longer version.

Regularly inspect the hoist and, if any of the following defects are present, request a full inspection by a qualified professional: excessive wear, damage to the trolley, damage to the hook and accessories, broken or deformed loose anchors, chain that does not hang freely or skips, or shows signs of wear, bends, nicks, stretching, corrosion, or twisting, load slipping, inability to lift the load, damaged hoist housing, or illegible markings.

Grade 80 Lifting Chain

The Grade 80 lifting chain is a high-strength chain, commonly used in hoists and other lifting applications due to its durability. Made of alloy steel, it has a specific strength rating to withstand heavy loads in various material handling tasks. The Grade 80 chain is suitable for manual hoists or low-intensity electric hoists, in environments with low abrasiveness.

Main Specifications:

- Standard: EN 818-7

- Material: Alloy Steel, Grade T, Type T

- Application: Suitable for lifting purposes

- Environmental Considerations: Lifting chains must not be immersed in acidic solutions or exposed to acidic gases.

- Use: The lifting chains must be smoothly guided by the sprockets, avoiding twists.

- Lubrication: Keep the chain clean and free of dirt or sand to ensure its free movement.

Grade 80 Lifting Chain for Chain Hoists and Lever Hoists (EN818-7)

Surface Finish: Black Oxide or Electrolytic Zinc Plated.

| Item Number | Size (mm) | Chain Pitch (mm) | Minimum Internal Width (mm) | Maximum External Width (mm) | Length in 11 Steps (mm) | WLL (kN) | Test Load (kN) | Minimum Breaking Load (kN) | Mass per Unit Length (kg/m) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

| G8H0412 | 4 | 12 | 4,8 | 13,6 | 132 | 0,5 | 12,6 | 20,1 | 0,35 | 501020412 |

| G8H0515 | 5 | 15 | 6,0 | 17,0 | 165 | 0,8 | 19,6 | 31,4 | 0,55 | 501020515 |

| G8H0618 | 6 | 18 | 7,2 | 20,4 | 198 | 1,1 | 28,3 | 45,2 | 0,78 | 501020618 |

| G8H0721 | 7 | 21 | 8,4 | 23,8 | 231 | 1,5 | 38,5 | 61,6 | 1,06 | 501020721 |

| G8H0824 | 8 | 24 | 9,6 | 27,2 | 264 | 2,0 | 50,3 | 80,4 | 1,38 | 501020824 |

| G8H0927 | 9 | 27 | 10,8 | 30,6 | 297 | 2,5 | 63,6 | 102 | 1,78 | 501020927 |

| G8H1030 | 10 | 30 | 12,0 | 34,0 | 330 | 3,2 | 78,5 | 126 | 2,20 | 501021030 |

Reviews

There are no reviews yet.