Manual Cart Type PT-FA

SKU Code: 1303

The manual trolley (also known as a simple trolley/beam-type trolley) is designed for precise positioning or easy movement of heavy loads and is compatible with manual and electric hoist equipment.

Product Overview:

The PT-FA type H-Lift manual trolley is designed for quick installation on beams. The trolley width can be adjusted by turning the central rod with an eyelet clockwise or counterclockwise. After connecting a hoist (sold separately), the central rod is locked to prevent accidental changes in width.

The design with anti-fall plates ensures greater safety, protecting the wheels and preventing damage from collisions with the end stops of the track.

The cart is equipped with anti-tip bars and wheels with permanently lubricated ball bearings, ensuring smooth operation.

This product complies with the Machinery Directive 2006/42/EC and the EN 13157 standard.

Our manual carts can be customized to accommodate various track widths within standard and extended beam ranges.

Specifications:

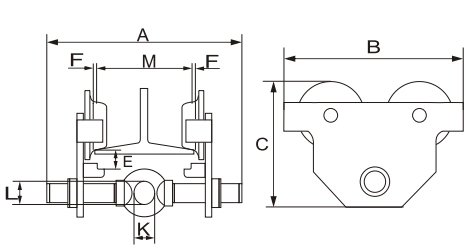

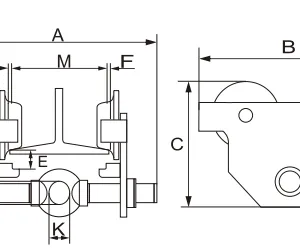

| SKU Code | Nominal Load (kg) | Test Load (kN) | Minimum Curve Radius (m) | Dimensions (mm) | Adjustable Beam Width (mm) | Net Weight (kg) | Product Code |

|---|---|---|---|---|---|---|---|

| PTFA005 | 500 | 7,35 | 0,9 | A: 292, B: 377, C: 225, E: 173, F: 33, K: ≈3, L: 25, M: 30 | 55-220 (Standard), 160-305 (Extended) | 8,2 | 130300500 |

| PTFA010 | 1000 | 14,7 | 1,0 | A: 300, B: 385, C: 252, E: 188, F: 31, K: 30, L: 35, M: 58 | 58-220 (Standard), 160-305 (Extended) | 10,3 | 130301000 |

| PTFA020 | 2000 | 29,4 | 1,2 | A: 310, B: 395, C: 300, E: 226, F: 32, K: 40, L: 47, M: 66 | 66-220 (Standard), 160-305 (Extended) | 17,5 | 130302000 |

| PTFA030 | 3000 | 44,1 | 1,3 | A: 324, B: 409, C: 360, E: 289, F: 46, K: 48, L: 58, M: 74 | 74-220 (Standard), 160-305 (Extended) | 30,7 | 130303000 |

| PTFA050 | 5000 | 73,5 | 1,4 | A: 329, B: 414, C: 392, E: 313, F: 47, K: 60, L: 70, M: 90 | 90-220 (Standard), 160-305 (Extended) | 42,4 | 130305000 |

Related Products:

- Talha Manual Type LH-A

- Beam Clamp Type BC

- Universal Lifting Clamp Type ULC

- Chain Paddle Type CH-B

Safe Use of Cart:

Manual trolleys and H-Lift geared trolleys are an effective solution for moving heavy loads along an I-beam or similar rail. It consists of a trolley frame, wheels/rollers, and a suspension device for the secure connection of the load.

Simple carts are ideal for infrequent or short-distance movement. However, due to manual operation, a maximum load of 3 tons (3,000 kg) is recommended.

For heavier loads or more frequent use, alternative models may be more suitable.

Chain Trolleys for Hoist

Trolleys with gears operated by manual chain are ideal for applications with infrequent movement or short distances. They are also suitable for lifting loads on beams with heights where simple trolleys may not be practical. Manual chain trolleys offer precise load positioning.

The carts are operated by pulling the manual chain, which turns a sprocket, which is directly connected to the cart wheels by gears or chains. These carts are ideal for:

- Load capacities over 3 tons (3000 kg)

- Height of the top beam at 6 meters (20 feet) above the operator's floor

- Precise load positioning

Manual chain hoists are highly effective for moving heavy objects with precision, even in hard-to-reach locations.

Strollers and Gear-Driven

Push carts and gear carts are commonly used in sectors such as manufacturing, construction, and warehousing to move heavy loads, such as machines, equipment, and materials. They are particularly useful in areas where overhead cranes are not feasible or practical.

These trolleys can be pushed manually along a beam or can be equipped with a gear system to facilitate the movement of heavier loads. The gear system can be operated by a crank or an electric motor. This makes it easier to move the trolley along the beam.

For use, the trolley is connected to the load through a suspension system, such as chains or slings. Once positioned on the beam, it can be moved manually or through the gear system. The trolley is designed to stop or start as needed to position or transport the load.

Push carts and gear carts are available in various sizes and weight capacities to meet different needs. Some models include features such as adjustable width and anti-derailment devices to ensure stability and safety during use.

Safety Guidelines

Always:

- Store and handle the carts properly.

- Inspect the carts, pulley sets, and accessories before use and storage.

- Make sure the wheel profile matches the beam type.

- Confirm that the width of the cart is properly adjusted for the beam.

- Make sure the beam has stops.

- Push the load instead of pulling it on a hand truck.

Never:

- Do not expose the carts to chemicals, especially acids, without consulting the supplier.

- Do not force or fit suspension hooks onto a load bar.

- Drop or throw the carts.

- Do not expose the carts directly to harsh environments, such as water jets or steam, without consulting the supplier.

- Do not use carts with notched or damaged wheel flanges.

- Avoid pulling the carts sideways at an inclined angle.

Choosing the Right Cart

Na HQLifting, we offer a variety of trolleys designed for different applications. Be sure to select the appropriate trolley based on load capacity, beam compatibility, and your specific operational needs. Choose a trolley that provides safety, durability, and efficiency for your lifting and load handling operations.

Load Capacity and Range of Lift Truck Options

HQLifting offers a variety of lifting trolleys, equipped with load eyes or suspension rings, designed to accommodate hook hoists or integrate directly into the hoist structures. Our lifting trolleys come in various configurations, including push/pull types, with manual gear and chain, and electric travel systems. When selecting a lifting trolley, consider the following factors:

- Load Capacity and Type of Lifting Car: Choose between load eye bolt/suspension ring settings or integrated hoists, offering push/pull options, with manual or electric gear and chain.

- Type of Hoist: Make sure the lift truck is compatible with the hoist that will be used.

- Size and Track Profile: Check if the size and profile of the rail match the specifications of the lifting car.

- Environmental Considerations: If operating in high-risk areas or environments exposed to elements such as water, steam, hazardous materials, or extreme temperatures, consult HQLifting for guidance.

Storage and Handling of Lifting Cars

Proper storage and handling are crucial to maintaining the performance and longevity of your hoist. Users typically unload the hoists for storage, leaving the hoists in place. To ensure durability and prevent damage, follow these guidelines:

- Avoid Storing Damaged Lift Cars: Inspect all parts before storing. Never put a damaged lift car back into service.

- Keep the Lifting Cars Dry and Clean: Store them in a protected environment, avoiding moisture and corrosion risks.

- Store the Accessories Separately: Operating chains, suspended controls, and similar components can be removed, clearly labeled, and stored separately to avoid damage.

- Handle with Care: Never drop or throw lifting cars to avoid structural damage.

Installation and Commissioning of Lifting Cars

Follow all the supplier's installation instructions to ensure the safe and proper operation of your lifting vehicle. The installation must be combined with the hoist instructions, noting the following:

- Operating Rail Condition: Make sure the track is level, has a smooth running surface, and is equipped with stops that fit securely into the lift car frame or the rolling surfaces of the wheels.

- Correct Width and Setup of the Lift Car: Set the width of the forklift precisely, distribute the shims evenly along the centerline, and check that the wheel profile matches the rail section. Properly adjust the anti-tip devices.

- Assembly Verification: If the lift truck was disassembled during setup, confirm the correct reassembly, with all bolts, nuts, and components properly tightened. Make sure the stops are in place (if previously removed).

Safe Use Guide for HQLifting Elevating Vehicles

The safe operation of HQLifting hoisting vehicles is closely linked to the hoist system that supports them. To avoid accidents and maintain efficiency, follow these precautions:

- Inspect the Equipment Before Use: Do not use defective lifting cars, hoists, or accessories.

- Load Positioning: Position the lifting vehicle directly above the center of gravity of the load. Avoid side loading, which can cause tipping, rail damage, or derailment.

- Push vs. Pull Techniques: When using push/pull lift trucks, always push the load instead of pulling it to minimize the risk of swinging and loss of control.

Inspection and Maintenance in Use

Regular inspections and maintenance ensure the longevity and reliability of HQLifting lift trucks. Maintenance programs can be aligned with those of the hoists to optimize efficiency and safety.

The rewritten content is now formatted according to your specifications. Please let me know if you need any modifications or have other requirements!

Make sure that the talha be clean and regularly lubricate your moving parts. Make sure that the bearing surfaces of the wheels and the contact surfaces of the rails are free of contaminants, including lubricating oil.

Inspect the talha regularly. If any of the following defects are present, have a qualified technician inspect the talha:

- Wear on the surface and on the wheel flange/rim

- Loose wheels and pins

- Loose or missing nuts

- Side plates, support shafts or deformed suspension arms

- Worn or damaged manual chain

- Defect in the controls

- Worn or chipped drive gears

- Damaged identification

Reviews

There are no reviews yet.