Talha 5 Ton Chain Hoist with 10 Meters of Lift and Winch for Heavy Loads

Product Number: 1201

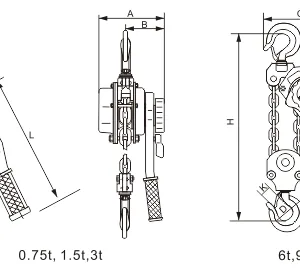

The lever hoist is a manual device designed to lift, lower, or pull heavy loads by applying or releasing tension. The lifting capacity of this hoist ranges from 750 kg to 9,000 kg.

Features

- Lightweight construction, but durable

- Automatic brake system with double ratchet

- Minimum force required to lift the maximum load

- Thick friction discs, asbestos-free

- Free travel mechanism for quick chain adjustment

- Forged alloy steel hooks with safety lock

- High-quality alloy steel charging current

(Standard 20Mn2, SAE 8620 optional) - Each hoist is tested with 1.5 times the rated load

Product Description

A Alavanca H-Lift Handle (Model LH-A) It is designed for industrial lifting and pulling applications. Its innovative design features forged hooks with safety locks and gradual deformation. The unique lever system of this hoist requires minimal force, allowing users to lift, suspend, and lower loads safely and reliably. The freewheel mechanism allows quick tensioning of the chain before operating the lever.

To ensure safety, a limiter is installed on the chain during installation as a safety device.

This hoist was built for high performance and reliability. The lever hoist design minimizes operational effort, making it easier to handle heavy loads. Whether you are lifting, pulling, or tensioning, this hoist offers exceptional efficiency and smooth operation.

Main Features:

- High Strength Grade 80 Load Chain: High-strength alloy steel designed for harsh industrial environments.

- Low Force Operation: Minimum force required to lift heavy loads.

- Security Resources: In case of overload, the forged hooks deform, preventing the chain from breaking, and are equipped with reinforced safety latches.

- Optional Resources: Overload protection, shipyard hooks, needle bearings, and lower hook with bearing for greater durability.

Safety Compliance

A Lever Handle H-Lift is in full compliance with industry standards, including:

- EN13157

- ASME B30.21

- AS1418.2

- SANS 1636

Note: Several optional settings are available to meet your individual needs, ensuring that you get the most suitable hoist for your application.

Available Options:

- Overload protection

- Lower hook with bearing

- Shipyard hooks

- Needle bearings between the sprocket and the side plates

If you need a hoist for light or heavy use, the Alavanca H-Lift Handle Model LH-A offers the performance and reliability needed to complete all your lifting tasks.

Safe Use Tips:

- Always visually inspect the hoist before use.

- Make sure the chain is tensioned for the best performance.

- Use the bucket within the specified capacity range.

Alavanca H-Lift Handle (Ratchet)

Overview

A Lever Handle H-Lift, also known as ratchet handle ou lever stroke, is a robust mechanical lifting equipment designed to lift and move heavy loads with ease. This hoist is particularly suitable for situations where manual lifting is required and electrical or hydraulic options are not available or are impractical.

Features and Specifications

Technical Details

| Item No. | Nominal Load (t) | Standard Lifting Height (m) | Load Test (kN) | Force Required to Lift the Nominal Load (N) | Number of Extensions | Charge Current | Dimensions (mm) | Net Weight (kg) | Additional Weight per Meter (kg) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

| LHA075 | 0,75 | 1,5 | 11,0 | 140 | 1 | 6×18 | A: 148, B: 88, C: 135, D: 37, Hmin: 320, L: 290, K: 26 | 6,3 | 0,8 | 120100750 |

| LHA150 | 1,5 | 1,5 | 22,1 | 240 | 1 | 8×24 | A: 176, B: 102, C: 162, D: 45, Hmin: 380, L: 420, K: 32.5 | 11 | 1,4 | 120101500 |

| LHA300 | 3 | 1,5 | 44,1 | 320 | 1 | 10×30 | A: 195, B: 109, C: 211, D: 50, Hmin: 480, L: 420, K: 37 | 18,7 | 2,2 | 120103000 |

| LHA600 | 6 | 1,5 | 88,2 | 340 | 2 | 10×30 | A: 195, B: 109, C: 254, D: 64, Hmin: 620, L: 420, K: 46 | 30 | 4,3 | 120106000 |

| LHA900 | 9 | 1,5 | 132,3 | 360 | 3 | 10×30 | A: 195, B: 109, C: 319, D: 85, Hmin: 700, L: 420, K: 50 | 41,2 | 6,5 | 120109000 |

Note: Other lift lengths are available.

Related Products

- Traction Pulley with Steel Cable (Tirfor Type)

- Clamp/Clip for I-Beam Type BC

- Universal Lifting Clip/Clamp Type ULC

- Manual Chain Hoist Type CH-B

Safe Use of Lever Hoists

Lever hoists like the Lever Handle H-Lift provide a safe and efficient manual lifting solution, ideal for handling heavy loads in various sectors such as construction, manufacturing, and mining. Operation is carried out through a ratchet and pawl mechanism, which ensures precise load control and lifting. The chain or steel cable, connected to the hoist, is wound onto a drum inside the hoist body. By pulling the lever, the ratchet engages, which raises or lowers the load smoothly and safely.

In situations where electric or hydraulic power is not available, lever hoists are indispensable tools and are an essential part of manual lifting operations.

Lever Handle: Compact and Durable Lifting and Dragging Solutions

The lever hoist, also known as a manual hoist or manual chain hoist, is a portable lifting device designed for lifting and pulling applications. These hoists are compact, durable, and easy to operate by a single person. They are available in various sizes and lifting capacities, allowing you to select the right hoist for the weight of the load you need to lift.

How to Use a Lever Hoist?

After securing the top hook and the load, follow these steps:

- Raise the Load: Move the lever to the lift position (↑) and operate the lever with a pumping motion to raise the load.

- Download the Load: Move the lever to the lowering position (↓) and operate the lever to lower the load.

- Adjust the Chain Length: Move the lever to the neutral (center) position. Now the chain can be pulled in both directions, allowing you to quickly adjust the lower hook to the desired position.

Hoist Suspension and Load Securing

To suspend a lever hoist, connect the top hook to a secure support, such as a shackle, beam clamp, or trolley. The bottom hook can be connected directly to the load if the load has suitable fittings or through a lifting sling with shackles. For pulling or tensioning, the top and bottom hooks are generally secured using lifting slings.

Safety Guidelines

Always:

- Store and handle the lever hoist properly.

- Inspect the hoist and accessories before use and before storage.

- Make sure the hooks are firmly seated, with no lateral pressure on the end.

- Check the brake operation.

- Check if the lower hook can reach its lowest position without touching the chain stop.

- Follow safe sling operation practices and the manufacturer's instructions for equipment use.

Never:

- Never expose the lever hoist to chemicals, especially acids, without consulting the manufacturer.

- Não substitua a corrente de carga por uma corrente mais longa sem consultar o fornecedor.

- Do not extend the lever or use excessive force to operate the hoist.

- Avoid dropping, throwing, or dragging the lever hoist.

- Do not allow oil or grease to come into contact with the brake.

- Do not expose the hoist directly to water, steam, or other environmental factors without consulting the supplier.

Choosing the Right Lever Hoist

Lever hoists are available in a variety of capacities and with link chain or roller chain. When selecting the right hoist, consider the following factors:

- Type of Current: Choose between link chain or roller chain.

- Lifting Capacity and Reach: Make sure the hoist can handle the weight and height required for your task.

Lever hoists are versatile and can be used in various locations for lifting and pulling tasks. If the hoist is used in a high-risk area, exposed to harsh environments, water, steam, hazardous materials (e.g., acids or chemicals), or extreme temperatures, it is essential to consult the supplier.

Storage and Handling of Lever Hoists

- Never put a damaged hoist back in the storage.

- Make sure the hoist is dry, clean, and protected against corrosion.

- Store the hoist by hanging it on the suspension hook and keeping the chain off the ground.

- Avoid dropping, throwing, or dragging the lever hoist.

- Do not galvanize or perform any electrolytic treatment on load-bearing parts without the supplier's approval.

Installation and Commissioning

Follow the specific installation instructions provided by the supplier. Test the hoist to ensure it is working properly, including checking the effectiveness of the brake. Make sure the chain moves smoothly and without twists. Also, ensure that the lower hook can reach its lowest position and that the chain does not come into contact with the end stops.

Safe Use of Lever Hoists

Before using a lever hoist, make sure you understand how to operate the equipment and follow the correct load securing procedures. Never use a hoist or accessories that are defective. Ensure that the load securing arrangement is correct, that the hoist is securely mounted, and that the chain is not twisted. Avoid using the load chain as a tie-down.

By following these guidelines, you can safely and effectively use lever hoists for a variety of lifting and moving tasks.

Brand Name: HQLifting

Safety and Maintenance Guide for Lever Hoists

Checks Before Use:

Before starting the lift, make sure the landing area is properly prepared. Lift the load slightly off the ground and stop the lift to check the reliability of the lever hoist and the type of sling.

- Never use an extension cord (as a tube) to force the hoist activation.

- Prevent the load from swaying uncontrollably.

- When lowering loads, be careful to protect body parts such as fingers and toes.

Checks and Maintenance During Use:

Follow the specific maintenance instructions provided by the manufacturer, paying special attention to lubricating and cleaning the load chain, removing any debris. It is essential to periodically check the brake's operating conditions. The brake must be free of oil and grease. Replacing the load chain with a longer one is strictly prohibited without consulting the manufacturer.

Regularly inspect the lever hoist and, if any of the following defects are found, deliver the hoist to a qualified professional for a complete inspection:

- Wear

- Damage to hooks and accessories

- Deformed or damaged end stops

- Chain showing wear, bends, grooves, elongation, cracks, corrosion, knots, twists, or improper operation

- Load slipping or difficult to be lifted

- Damaged hoist housing

- Bent or broken activation lever

- Illegible markings

Grade 80 Load Chain

The Grade 80 load chain is widely used in lifting applications, including manual hoists and low-speed electric hoists. It is particularly suitable for environments where there are no abrasive conditions. This alloy steel chain has a high strength rating and is designed to handle heavy loads in lifting and material handling tasks.

- Chain Specifications:

- Short link chain for lifting, in accordance with standard EN 818-7

- Chain for hoist with precise tolerance, Class T, Type T

- Manual or electric low-speed hoists in non-abrasive environments

- Maintenance Requirements:

- The hoist chain must not be immersed in acidic solutions or exposed to acidic vapors.

- Make sure the hoist chain enters and exits the ratchet smoothly and without twists.

- To extend the lifespan, the hoist chain must be lubricated, especially in the contact areas of the links.

- Keep the hoist chain clean, ensuring it moves freely and avoids contamination by dust and sand.

Surface Finish Options

- Oxidized Black Finish

- Electrolytic Zinc

Product Specifications for Grade 80 Load Chain

| Item Code | Size (mm) | Distance between Links (mm) | Width (Minimum Internal mm) | Width (Maximum External mm) | Length of 11 x Pitch (mm) | Workload Limit (WLL) (kN) | Test Load (kN) | Minimum Breaking Load (kN) | Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|---|

| G8H0412 | 4 | 12 | 4.8 | 13.6 | 132 | 0.5 | 12.6 | 20.1 | 0.35 |

| G8H0515 | 5 | 15 | 6.0 | 17.0 | 165 | 0.8 | 19.6 | 31.4 | 0.55 |

| G8H0618 | 6 | 18 | 7.2 | 20.4 | 198 | 1.1 | 28.3 | 45.2 | 0.78 |

| G8H0721 | 7 | 21 | 8.4 | 23.8 | 231 | 1.5 | 38.5 | 61.6 | 1.06 |

| G8H0824 | 8 | 24 | 9.6 | 27.2 | 264 | 2 | 50.3 | 80.4 | 1.38 |

| G8H0927 | 9 | 27 | 10.8 | 30.6 | 297 | 2.5 | 63.6 | 102 | 1.78 |

| G8H1030 | 10 | 30 | 12.0 | 34.0 | 330 | 3.2 | 78.5 | 126 | 2.2 |

Reviews

There are no reviews yet.