Guide for Safe Use and Operation of Trolleys

Never:

- Use chemicals, especially acids, without consulting the supplier.

- Do not force the fitting of the trolley suspension hook into the load support frame.

- Play or drop the trolley.

- Expose the trolley directly to water mist, steam, etc., without consulting the supplier.

- Use a trolley with a damaged or worn flange.

- Apply an inclined side load on the trolley.

Choosing the Right Trolley

The trolleys are available in a variety of load capacities, equipped with a load hoist or a suspension loop for connection to a hook trolley (model with hook for load suspension) or an integrated trolley. Manual models (push/pull), manual chain models, and electric models are available. When selecting the correct trolley, be sure to consider the following:

- Capacity and type of trolley: Select the trolley based on the type of load attachment: hoist, suspension loop, or integrated suspension. Also consider the method of movement: manual (push/pull), with manual chain, or electric.

- Size and profile of the rail: Make sure the trolley matches the size and profile of the rail.

- Contact the supplier: Always consult the supplier if the trolley is used in high-risk areas or exposed to weather, water, steam, hazardous materials, or extreme temperatures.

Storage and Maintenance of Trolleys

When the trolleys are taken out of service and stored, protect them against damage and corrosion. If the trolleys are stored individually, the following guidelines must be followed:

- Condition: Never store a damaged trolley. Trolleys must be dry, clean, and protected against corrosion.

- Storage location: Store the trolleys in a clean, dry area, protected against damage. Remove and clearly identify components such as operating chains, pendant controls, and hoses, storing them separately to avoid damage.

- Careful handling: Never drop or throw the trolleys.

Installation and Commissioning

When installing a trolley, always follow the specific installation instructions provided by the supplier along with the trolley manual. Pay special attention to the following:

- Rail condition: Make sure the rail is level, aligned, and equipped with safety stops that prevent excessive trolley movement.

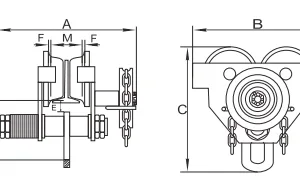

- Trolley alignment: Check that the trolley width is properly adjusted, with spacers (shims) evenly distributed on both sides of the central axle. Make sure the wheel profile matches the rail section and that the anti-tilt devices are correctly set.

- Reassembly: If the trolley was disassembled during installation, make sure all components have been reassembled correctly. Check that all screws and nuts are in place and properly tightened. Also replace any stoppers that were removed.

Safe Use of Trolleys

The safe operation of a trolley depends greatly on the type of trolley equipped, but the general guidelines include:

- Avoid using defective equipment: Never use a trolley, hoist, or other damaged accessories.

- Proper load positioning: Make sure the trolley is positioned directly above the center of gravity of the load. Never apply load laterally or at an angle on the trolley, as this can cause tipping, rail damage, or derailment.

- Load handling: When using a manual trolley, always push the load instead of pulling it, and take the necessary safety precautions.

Dynamic Load

Inspection and Maintenance in Use

The maintenance of the pulleys must be incorporated into the crane maintenance plan, ensuring that the pulleys remain free of dirt and that their moving parts are lubricated regularly. The rolling surfaces of the wheels and the contact surfaces with the rails must be free of contaminants, including lubricants.

Regularly inspect the pulleys and, if any of the following defects are present, immediately send them for inspection by a qualified professional: excessive wear, damage to the bearing surface or wheel flange, loose wheels and axles, unsecured nuts, deformed side plates, deformed load bars or suspension eyes, damaged or worn chain, control failure, worn or chipped drive gears, and illegible identification information.

Reviews

There are no reviews yet.