Below is the reviewed product information in Markdown format:

markdown

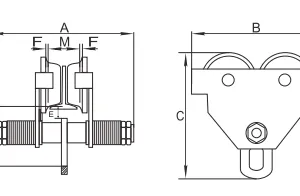

Chain Trolley with Gears PT-CA | Product Code: 1302

O Chain Trolley with Gears is a device specially designed to facilitate the smooth displacement of heavy loads along suspended beams, typically I beams (I beams). Different from a simple or manual trolley, this model integrates a gear system, guaranteeing a easy and controlled operation.

Features and Benefits

- Manual Chain Operation: When pulling the manual chain, the gear system is activated, allowing precise and smooth movement along the beam with minimal effort.

- Adjustable Beam Width: Through adjustable spacers, the trolley can accommodate different sizes of I-beams.

- Enhanced Security: Has anti-fall devices, which not only provide additional security but also prevent damage when the wheels come into contact with the limit switches.

- Smooth Lateral Movement: The wheels with ball bearings have permanent lubrication, ensuring long-lasting performance.

- Standard and Customizable Manual Current: Comes with a standard 3-meter manual chain; other lengths available upon request.

- Compliance and Durability: Totally in accordance with Machinery Directive 2006/42/EC (European Directive), ensuring quality and reliability.

- Versatile Applications: Suitable for beams of standard and extra-long lengths, being versatile for various industrial environments.

Technical Specifications

| Product Code | Nominal Load | Test Load (kN) | Required Traction Force (N) | Minimum Curve Radius (m) | Dimensions (mm) | Adjustable Beam Width (mm) | Net Weight (kg) |

|---|---|---|---|---|---|---|---|

| GTCA010 | 1t | 14.7 | 44 | 1 | 390x492x260 | 64-203 [Standard] / 102-305 [Extended] | 19.9 / 21.1 |

| GTCA020 | 2t | 29.4 | 80 | 1.1 | 400x502x300 | 88-203 [Standard] / 102-305 [Extended] | 28.5 / 30.6 |

| GTCA030 | 3t | 44.1 | 65 | 1.3 | 430x532x345 | 102-203 [Standard] / 102-305 [Extended] | 46 / 49.8 |

| GTCA050 | 5t | 73.5 | 90 | 1.4 | 444x544x390 | 114-203 [Standard] / 108-305 [Extended] | 57 / 60.8 |

| GTCA100 | 10t | 147 | 195 | 1.7 | 489x584x470 | 125-203 [Standard] / 117-305 [Extended] | 103 / 108.5 |

Related Products

- Lever Handle Model LH-A

- BC Beam Clip (Unknown full product name)

Carts for Moving Heavy Loads

A moving trolley is an important piece of equipment used to transport heavy loads along an I-beam or similar rail. It consists of a sturdy trolley frame, wheels or casters, and a suspension system to securely connect the load.

Manual Carts

Manual carts are ideal for situations where the cart is moved infrequently or for short distances. However, since operating these carts requires manual strength, it is recommended that the maximum load capacity for simple carts be limited to 3 tons (3000 kg) and that the beam height does not exceed 20 feet (6 meters) above ground level.

Chain Carts

Chain trolleys are ideal for applications where trolley movement is infrequent or for short distances and are suitable for situations where simple trolleys are not sufficient. They offer excellent load positioning capability.

The movement of the cart is performed by pulling the chain, which makes the sprocket turn. This wheel is connected to the cart's wheels through gears or chains. The use of carts of this type is recommended in the following situations:

- Load capacity over 3 tons (3000 kg):

- Height of the top beam 20 feet (6 meters) above ground level:

- Precise load positioning:

Strollers

Push carts are often used in industries such as manufacturing, construction, and warehousing. They assist in moving heavy loads in areas where overhead cranes are not feasible, such as machines, equipment, and materials.

These carts can be pushed manually or equipped with a gear system to facilitate the movement of heavier loads.

How to Use a Push Cart

- Connect the cart to the load using a suspension system, such as chains, straps, among others.

- Place the cart on the track.

- Move the cart along the track manually or using the gear system.

- Transport the cargo to the desired locations, starting, stopping, and positioning it as needed.

Push carts are available in various sizes and weight capacities to accommodate different applications. Some models also feature adjustable widths and anti-derailment systems for increased safety and stability.

Guidelines for Proper Use and Maintenance

Always:

- Store and handle the cart properly.

- Inspect the cart, pulleys, and accessories before use and during storage.

- Make sure the wheel profile is compatible with the rail.

- Check if the cart width is set correctly for the rail.

- Make sure the rail is installed with secure end stops.

- When using a push/pull cart, push the load instead of pulling it.

Never:

- Expose the cart to adverse conditions that may damage it or affect its performance.

Safety and Use Guide for Moving Carts

Limitations and Safety Warnings

- Avoid the use of chemicals (especially acids), unless you consult the supplier.

- Do not force the stroller suspension hook in a load bar.

- Never throw or drop the cart.

- Avoid exposing the cart directly to harsh environments, such as water or steam jets, unless you consult the supplier.

- Do not use carts with chipped or damaged flanges.

- Never apply lateral load to the cart at an angle.

Selecting the Right Cart

The trolleys come in various capacities and configurations, designed to accommodate hook hoists with load bars or integrated suspended hoists. Several models are available, including push/pull (manual) types, chain-driven, and motorized. When selecting a trolley, it is essential to consider the following:

- Capacity and Cart Type: Is the cart the type with a load bar/lifting eye or does it have an integrated hoist suspension?

- Type of Hoist: Ensure proper compatibility between the cart and the hoist.

- Size and Track Profile: Check if the cart matches the rail specifications.

- Supplier Inquiry: If the cart is used in high-risk environments (exposure to harsh environments, hazardous materials, or extreme temperatures), it is essential to consult the supplier.

Storage and Handling of Carts

When not in use, the trolleys must be properly stored to prevent damage and corrosion. If the hoist is removed for storage but the trolley remains in place, the following steps must be followed:

- Do not return damaged carts to the storage location. Make sure they are dry, clean, and well protected against corrosion.

- Store the carts in a clean and dry area to avoid damage. Removable components, such as operating chains and pendant controls, must be removed, clearly marked, and stored separately.

- Avoid dropping or throwing The carts to avoid any damage.

Installation and Commissioning

Always follow the specific installation instructions provided by the supplier. These guidelines should be considered together with the hoist instructions, paying special attention to:

- Movement Track: Make sure the rail is level, with a smooth rolling surface and positive stops that fit the frame or trolley flanges.

- Cart Configuration: The trolley must be set up with the correct width, with shims evenly distributed along the centerline. The wheel profiles must be compatible with the rail section. Properly adjust the anti-fall devices.

- Disassembly and Reassembly: If the cart is disassembled for installation, check that all components have been reassembled correctly. Make sure all screws and nuts are in place and properly tightened. Replace all removed stops.

Using Carts Safely

The safe operation of a cart depends on the hoist with which it is used. However, here are the main points for safe use:

- Defective Equipment: Never use a cart, hoist, or any damaged accessory.

- Proper Load Positioning: Always position the cart directly above the center of gravity of the load. Do not load the cart sideways at an angle, as this can cause it to tip over, damaging the rail or causing the cart to come loose and fall.

- Always Push, Never Pull: When using a push/pull type cart, always push rather than pull the suspended load. Exercise extreme caution to avoid any potential hazards, such as the load swinging or hitting obstacles.

Dynamic Loads

Inspection and Maintenance in Service

Maintenance can be performed simultaneously with the daily maintenance of the manual hoist, ensuring that the trolley is clean and that all moving parts are regularly lubricated. Keep the wheel bearing surfaces and the rail contact areas free of contaminants, including lubricants.

Perform routine inspections on the trolley. If any of the following defects are detected, send the equipment for a complete inspection by qualified personnel:

- Signs of wear observed

- Damage observed on the running surface or wheel flange

- Loose axle rods or pins

- Loose nuts

- Side plates, load bars, or deformed suspension eyes

- Damaged or worn manual chain

- Defective or damaged controls

- Worn or chipped drive gears

- Illegible identification

Make sure to follow the correct maintenance procedures to ensure operational safety and extend the service life of the hqlifting trolley system.

Reviews

There are no reviews yet.