Strollers and Gear Carts

Overview

Push carts and geared carts are essential tools used in industries such as manufacturing, construction, and warehousing to move heavy loads along a track. These carts can be pushed manually or equipped with a gear system to assist in moving heavier loads, making them ideal for areas where overhead cranes are not feasible.

Simple Carts

Simple trolleys are more suitable for relatively short movements. Since manual operation requires a certain amount of force, it is recommended to limit the capacity of simple trolleys to a maximum of 3 tons (3,000 kg) and the beam height not to exceed 6 meters above the operator's floor level.

Manual Chain Gear Carts

For carts that are used less frequently or for short-distance movements, manual chain carts are a better option and are suitable for situations where simple carts are not feasible due to the weight of the load or the height of the beam.

These carts offer excellent load positioning capacity, making them an excellent choice for precise positioning of heavy objects.

The movement of the cart is activated by pulling the manual chain, which turns the manual chain wheel. This wheel is directly connected to the cart wheels through a gear system, allowing smooth and controlled movement. Carts operated by manual chain are particularly recommended for situations where:

- The capacity exceeds 3 tons (3,000 kg)

- The beam elevation is over 6 meters above the operator's floor level

- Precise positioning of the load is required

Features of Strollers and Gear Strollers

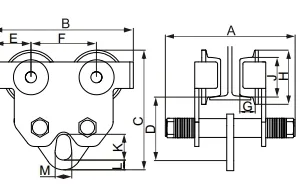

Push carts and gear carts can be manually pushed along a track or equipped with a gear system to facilitate the movement of heavy loads. With a gear system, operators can turn a crank or use a motor to drive the cart along the track.

These carts are commonly used to move heavy equipment, machinery, and materials, especially in environments where overhead cranes are not suitable. The cart is connected to the load through a suspension system, such as chains or straps, and moves along the track. The cart can be stopped or started as needed, allowing precise positioning of the load.

Security and Stability Resources

Push carts and gear carts come in various sizes and weight capacities to meet different application needs. Some models are also equipped with safety and stability features, such as adjustable width and anti-derailment devices, ensuring smooth operation even in complex working conditions.

Maintenance and Safety Guidelines

Always:

- Store and handle the carts properly.

- Inspect the carts, carts, and accessories before use and during storage.

- Make sure the wheel profile is compatible with the rail.

- Check if the cart width is properly adjusted for the rail.

- Make sure the rail is installed with reliable stops.

- Push instead of pull suspended loads on push/pull carts.

Never:

- Do not expose the carts to chemicals, especially acids, without consulting the supplier.

- Force the hook of a cart at a cargo attachment point.

- Do not throw or drop the carts.

- Expose the carts to humid environments, such as water mist or steam, without consulting the supplier.

Safety and Selection Guide for Trolley Hoists

Important Safety Precautions When Using Hoist Carts

- Never use hoist trolleys with wheels that have damaged edges.

- Avoid submitting hoist trolleys to inclined lateral loads.

Selecting the Appropriate Hoist Trolley

The furniture hoist trolleys come in different load capacities and can be equipped with a load beam or eyelet designed to accommodate a block with a hook, or they may have an integrated pulley set. There are several models of hoist trolleys, including manual drive (push/pull type), chain-operated, and electrically driven. When choosing a hoist trolley, consider the following factors to ensure its suitability:

- Capacity and type of hoist trolley (load beam/eye or integrated pulley set)

- Type of actuation (manual push/pull, by chain or electric)

- Type of pulley set to be coupled

- Size and profile of the rail

It is recommended to consult the supplier for additional guidance if the hoist trolley is used in high-risk areas, exposed to harsh environments such as water, steam, hazardous materials, or extreme temperatures.

Storage and Handling of Hoist Trolleys

Generally, users remove the hoist block for storage, leaving the hoist trolley in place. It is essential to protect the hoist trolley against damage and corrosion. When storing hoist trolleys separately, follow these guidelines:

- Never store damaged hoist trolleys. Make sure they are clean, dry, and protected against corrosion.

- Store the hoist trolleys in a dry and clean place, protected against damage.

- Remove and label components such as drive chains, control push buttons, etc., and store them separately to avoid damage.

- Never drop or throw hoist trolleys.

Installation and Commissioning of Hoist Trolleys

Always follow the specific installation instructions provided by the supplier. Also refer to the winch instruction manual, paying special attention to the following:

- Check if the bearing rail is level, has a uniform rolling surface, and is equipped with travel limiters that fit the hoist trolley frame or the surface of the wheels.

- Make sure the hoist trolley width is properly adjusted, with shims evenly distributed along the centerline, and that the profile fits the rail/beam section. The anti-fall safety devices must be installed correctly.

- If the trolley hoist was disassembled for installation, make sure all components have been reassembled correctly. Tighten all screws, nuts, and fasteners. If the stops were removed, make sure to replace them.

Safe Use of Hoist Trolleys

Safety in the operation of the hoist trolley largely depends on the pulley used, but general precautions include:

- Never use a defective hoist trolley, pulley block, or accessories.

- Position the hoist trolley directly above the center of gravity of the load. Never apply load laterally on the hoist trolley, as this can cause tipping, damage the rail/beam, or cause the trolley to fall.

- In manual hoist trolleys (push/pull), always push suspended loads instead of pulling them, avoiding load swinging.

It is essential to follow these safety measures to ensure the safe and efficient operation of the system.

Inspection and Maintenance in Service

Maintenance can be combined with the trolley, ensuring that it remains clean and that its moving parts are properly lubricated. It is essential to keep the rolling surfaces of the wheels and the contact surfaces of the rails clean, avoiding any contaminants, including lubricants.

The trolley must be inspected regularly. If any of the following problems are detected, the trolley must be sent to qualified personnel for a complete inspection:

- Wear

- Damage to the tread and wheel flange

- Play in wheels and axles

- Loose nuts

- Deformation on the side plates, load bar, or suspension rings

- Damaged or worn lifting chain

- Control system failures

- Wear or chips on the drive gears

- Hard-to-read identification

Reviews

There are no reviews yet.