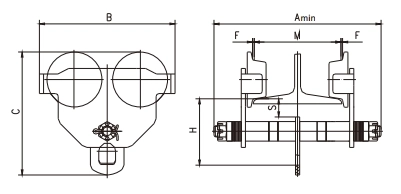

Double Beam Gear Cart GT-DB

Model Number: 1306

This series of double-girder gear trolleys, with precise design, offers rated load capacities (W.L.L. – Working Load Limit) from 500 kg to 50 tons. They are designed for precise positioning or easy movement of heavy loads and can be used with manual or electric hoists.

Main Features:

- High Precision: Cart wheels machined with precision and equipped with sealed ball bearings, which require no maintenance, for smooth operation.

- Design focused on safety: All manual carts come equipped with anti-fall bars.

- Double Beam Construction: Provides greater safety and reliability.

- Anti-Derailment Deflectors: They ensure greater safety, preventing damage to the wheels when they come into contact with the stops at the ends of the track.

- Smooth Operation: The wheels, with permanently lubricated ball bearings, provide smooth and easy movement.

- Equipped with hand chain: Standard operating height of 3 meters; longer lengths available upon request.

- Compliance: In full compliance with the Machinery Directive 2006/42/EC.

Especificações do Produto

The GT-DB gear trolleys are suitable for various flange widths, including the standard beam range (A) and the extended beam range (B), adjustable through spacers.

| Code | Nominal Load | Carga de Teste | Beam Width (mm) | Dimensions (mm) | Net Weight (kg) | Product Code |

|---|---|---|---|---|---|---|

| A | B | A | B | |||

| GTDB005 | 0.5t | 7.35kN | 50-152 | 50-203 | 240 | 290 |

| GTDB010 | 1t | 14.7kN | 64-203 | 64-305 | 310 | 395 |

| GTDB020 | 2t | 29.4kN | 88-203 | 88-305 | 320 | 425 |

| GTDB030 | 3t | 44.1kN | 100-203 | 100-305 | 330 | 435 |

| GTDB050 | 5t | 73.5kN | 114-203 | 114-305 | 350 | 450 |

| GTDB100 | 10t | 147kN | 124-203 | 124-305 | 362 | 462 |

| GTDB200 | 20t | 245kN | 136-203 | 136-305 | 392 | 512 |

| GTDB300 | 30t | 367.5kN | Not applicable | 175-305 | Not applicable | 512 |

| GTDB500 | 50t | 612.5kN | Not applicable | 175-305 | Not applicable | 512 |

Related Products

- Left Lever Handle LH-A

- Beam Clamp BC

- Universal Lifting Clamp ULC

- Chain Section CH-B

Safe Use Guide for Manual and Gear Carts

H-Lift (Hailingfu) Manual and Gear Carts

Manual and geared trolleys are robust tools, designed to move heavy loads along I-beams or similar rails. They consist of a trolley frame, wheels or rollers, and a suspension system for connection to the load.

Simple Manual Cart

Simple manual carts are ideal for occasional or short-distance movements. Because manual operation is more labor-intensive, it is recommended to limit the maximum load capacity of the simple cart to 3 tons (3000 kg). Additionally, it should not be used when the beam height exceeds 6 meters above the operator's level.

Gear Cart Driven by Chain

For situations with less frequent movement or that require greater load capacity, a trolley with chain-driven gears is an excellent option. This type is recommended for loads over 3 tons (3000 kg) and beam heights greater than 6 meters. Chain-driven trolleys are ideal for precise load positioning, as the chain operates a handwheel that drives the gears to move the wheels.

These carts can be pushed manually along the track or equipped with a gear system to facilitate the movement of heavier loads. The gear system allows the operator to move the cart using a crank or a motor, making it easier to transport large or bulky items.

Typical Applications

Manual and geared carts are widely used in various sectors, including manufacturing, construction, and warehousing. They are particularly useful in situations where the use of overhead cranes is not suitable or feasible. These carts assist in moving heavy objects, such as machines, equipment, and materials.

How to Use

To operate a manual trolley with gears, connect the load to the trolley using a suspension system, such as chains or slings. Then, position the trolley on the track; it can be moved manually or through the gear system. It can be stopped or activated as needed to position or reposition the load.

Safety and Features

Manual carts with gears are available in various sizes and capacities to meet different operational needs. Some models offer additional features, such as adjustable width and anti-derailment devices, to enhance safety and stability during use.

Best Practices:

- Always handle and store the cart properly.

- Inspect the cart and its accessories before each use and before storing it.

- Make sure the wheel flanges and other components are in good condition to ensure the best performance.

Handling and Safety Guidelines for Cars (Trolleys)

What to do:

- Ensure compatibility: Confirm if the car is suitable for the type of track.

- Adjust the car width: Check if the car width is set correctly to fit the rail.

- Install reliable stoppers: Make sure the rail is equipped with reliable stops.

- Push the load: Always push the suspended load in a push/pull cart; never pull it.

O que não fazer:

- Avoid exposure to chemicals: Never expose the car to chemicals, especially acids, without consulting the supplier.

- Do not force the installation of the suspension hook: Never force the hoist suspension hook on the load attachment point.

- Avoid car falls: Never throw or drop the car.

- Weather protection: Avoid exposing the car directly to water jets, steam, etc., without consulting the supplier.

- Check for damage: Do not use a car with damaged wheel flanges or with chips.

- Do not tilt the load sideways: Never load the car sideways at an angle.

How to Choose the Right Car

Movement trolleys are available in a variety of capacities, with load attachment points or suspension rings designed for hoist sets or as an integral unit incorporated into a hoist. They come in different configurations, including push/pull models, manual chain drive, and motorized travel. When selecting a trolley for your needs, consider the following:

- Capacity and car type: Choose between load securing points/lifting rings or integrated hoist suspension and consider whether you need a push/pull mechanism, manual chain drive, or motorized travel.

- Type of hoist: Consider the type of hoist that will be used with the car.

- Size and profile of the rail: Ensure compatibility with the size and profile of the rail.

- Supplier inquiry: For used cars in high-risk areas, harsh environments, exposure to hazardous materials, or extreme temperatures, always consult the supplier for guidance.

Storage and Handling of Cars

When cars are removed from a hoist for storage, they must be protected against damage and corrosion. Follow these guidelines for proper car storage:

- Proper storage conditions: Store the cars in a clean, dry area to prevent damage and corrosion.

- Damage prevention: Never return damaged cars to the storage area; make sure they are dry, clean, and free of corrosion before storing them.

- Components stored separately: The operating currents and suspended power controls must be removed, clearly labeled, and stored separately to avoid damage.

- Careful handling: Never drop or throw the cars during storage.

Installation and Commissioning

Follow the supplier's specific installation instructions and make sure to:

- Rail and stops: Check if the track rail is level, has a uniform rolling surface, and is equipped with positive stops that engage the car frame or the wheel contact surface.

- Correct car setup: Make sure the car width is set correctly, with shims evenly distributed along the centerline. Check that the wheel profile is suitable for the rail section and that the anti-tilt devices are properly set.

- Assembly: If the car was disassembled for installation, make sure all parts have been reassembled correctly. Make sure all screws, nuts, and components are securely fastened.

Safe Use of Cars

The safety in the operation of the cars depends greatly on the type of hoist used, but the following precautions should always be taken:

- Check for defects: Do not use defective cars, hoists, or accessories.

- Load alignment: The car must be located directly above the center of gravity of the load, avoiding misuse or overloading.

By following these guidelines, you can ensure the safe and efficient use of cars, reducing the risk of accidents and extending the equipment's lifespan.

Safe Operation and Handling

To avoid damage and ensure safe operation, it is forbidden tilt the cart laterally during loading, as this can cause tipping, resulting in damage to the tracks or causing the cart to come off the tracks, posing a serious hazard.

For carts pulled/pushed manually, always push instead of pull suspended loads. Deve-se prevent the load from shifting, to prevent instability and safety risks.

Inspection and Maintenance During Use

Daily maintenance of the cart can be performed simultaneously with the maintenance of the tow truck, but it must be ensured that the cart remains clean and that all moving parts are properly lubricated. The rolling surfaces of the wheels and the contact areas with the tracks must be kept clean, and free of contaminants, including lubricants.

Regular inspections are mandatory. If any of the following defects are detected, the cart must be delivered to a qualified professional for a complete inspection:

- Excessive wear

- Damage to the rim or wheel flange

- Loose or insecure axle wheels and pins

- Loose nuts

- Side plates, load bars, or deformed suspension eyes

- Worn or damaged manual chain

- Control failure

- Worn or chipped drive gears

- Illegible markings

Proper maintenance and timely inspections ensure the lifespan and operational safety of hqlifting cartsTM.

Reviews

There are no reviews yet.