Talha Manual Móvel 750kg with Trolley and Steel Structure for Handling in Warehouses

Product Number: 1102

The H-Lift manual chain hoist (model CH-G) is an essential lifting device designed to raise or lower heavy loads with ease. It operates through a manual chain mechanism, with internal gears that wind the chain to lift objects attached to a lower hook or at the end. This design ensures that minimal effort is required to lift loads up to 50,000 kg.

One of the biggest advantages of this hoist is that, since it does not require electricity, it is ideal for use in remote areas or with limited access to power. These hoists are versatile and can be used in various applications, such as machine installation, maintenance, and work at heights, including in confined spaces like mechanical workshops. They are equally effective in environments such as factories, laboratories, and power plants.

The manual chain hoist is an economical and efficient load lifting solution, with the added benefit of being operable by a single person. Its versatility makes it an ideal tool for various applications.

Main Features:

- Durable construction: Made of high-strength steel with a powder-coated finish.

- Sealed Bearings: Located between the sprocket of the load chain and the side plates for smooth operation.

- Additional Bearing: Includes an additional bearing for units with a nominal capacity of 1.5 tons or higher.

- Safe Brake System: Equipped with a dual-ratchet automatic brake system.

- High-quality friction pads: Extra thick and asbestos-free, ensuring safe operation.

- Forged league hooks: Designed to deform under overload before chain breakage, with reinforced safety locks.

- Alloy steel load current: Made with premium alloy steel (standard 20Mn2, optional SAE 8620).

- Galvanized Manual Chain: Medindo 5×23,7 mm.

- Resistance Test: Each hoist is tested for strength, with a test load of 1.5 times the rated capacity for units under 20 tons and 1.25 times the rated capacity for units 20 tons or larger.

- Compliance: Atende aos padrões EN13157, ASME B30.16, AS1418.2 e SANS 1594.

- Recursos opcionais: Proteção contra sobrecarga e gancho inferior com rolamento axial.

Especificações do Produto

| Product Code | Capacity (t) | Standard Lifting Height (m) | Test Load (kN) | Force Required to Lift the Nominal Load (N) | Number of Extensions | Charge Current | Dimensions (mm) | Net Weight (kg) | Additional Weight per Meter (kg) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

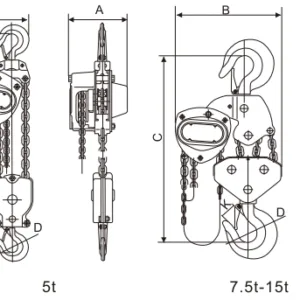

| CHG0025 | 0,25 | 2,5 | 3,68 | 235 | 1 | 4X12 | A: 114, B: 121, C: 280, D: 31, K: 19 | 6,5 | 1,2 | 110200250 |

| CHG0050 | 0,5 | 2,5 | 7,35 | 240 | 1 | 5X15 | A: 132, B: 148, C: 345, D: 35, K: 23 | 9,3 | 1,4 | 110200500 |

| CHG0100 | 1 | 2,5 | 14,7 | 250 | 1 | 6X18 | A: 151, B: 172, C: 376, D: 40, K: 26 | 12,2 | 1,6 | 110201000 |

| CHG0150 | 1,5 | 2,5 | 22,05 | 265 | 1 | 7.1X21 | A: 173, B: 196, C: 442, D: 45, K: 29.5 | 16,5 | 1,9 | 110201500 |

A talha manual de corrente H-Lift é uma ferramenta versátil, confiável e eficiente para elevação de cargas pesadas. Escolha HQLifting para soluções de elevação superiores e seguras!

Talha Manual de Corrente H-Lift

Visão Geral:

Nossa talha manual de corrente H-Lift é uma solução de elevação robusta e eficiente, projetada para aplicações pesadas. Disponíveis em diversas capacidades e comprimentos, estas talhas de corrente são projetadas para oferecer máxima confiabilidade e segurança em todas as operações de elevação.

Features:

- Durability: Construída com componentes de alta resistência, garantindo durabilidade em condições de trabalho adversas.

- Segurança: Equipada com recursos de segurança, como suspensão do gancho superior com trava de segurança e instruções de uso seguras de cabos de elevação.

- Flexibilidade: Disponível em tamanhos que variam de 500 kg a 5000 kg, para atender a diversas necessidades.

- Design Compacto: O design compacto e portátil garante fácil manuseio e armazenamento.

- Opções de Suspensão do Trolley: Adequado para várias larguras de viga com configurações ajustáveis para versatilidade.

Especificações da Talha:

| Model | Capacity (kg) | Altura de Elevação (m) | Chain Length (m) | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|---|

| CHG0200 | 200 | 2 | 2.5 | 29.4 | 335 |

| CHG0300 | 300 | 3 | 3 | 44.1 | 372 |

| CHG0500 | 500 | 3 | 5 | 73.5 | 380 |

| CHG0750 | 750 | 3 | 7.5 | 110.3 | 380 |

| CHG1000 | 1000 | 3 | 10 | 147 | 380 |

| CHG1500 | 1500 | 3 | 15 | 183.8 | 385 |

| CHG2000 | 2000 | 3 | 20 | 245 | 400 x 2 |

| CHG3000 | 3000 | 3 | 30 | 36.75 | 420 x 2 |

| CHG5000 | 5000 | 3 | 50 | 612.5 | 475 x 2 |

Note: Buckets with different chain lengths are also available upon request.

Related Products:

- LH-A Type Lever Handle

- Beam Clamp Type BC

- Universal Lifting Clamp Type ULC

- Simple Cart Type PT-CA

Safe Use Guidelines:

Always:

- Store and handle the manual chain hoist properly to ensure its good operation.

- Inspect the hoist and its accessories before each use and before storage.

- Make sure the top hook is equipped with a safety lock and is securely fastened.

- For trolley suspension, confirm that the trolley settings are adjusted to fit the width of the beam.

- Check if the lower hook reaches its lowest point without the chain being excessively stretched.

- Follow the guidelines for safe linga operations.

Never:

- Não exponha a talha de corrente a produtos químicos, especialmente ácidos, sem consultar o fornecedor.

- Do not replace with a longer lifting chain without consulting.

- Não force a operação da talha.

- Do not drop, throw, or drag the chain hoist.

- Prevent oil or grease from coming into contact with the brake components.

- Do not expose the chain hoist directly to water, steam, or harsh environments without consulting the supplier.

Selecting the Appropriate Hoist:

Selecting the correct manual chain hoist involves considering the following factors:

- Suspension Method: Hook type or cart type.

- Capacity and Elevation Range: Make sure the hoist meets the required capacity and lifting range.

- Use: Chain hoists are mainly used for vertical lifting. Consult the supplier for use in special environments, such as high-risk areas, chemically aggressive environments, or extreme temperature environments.

Storage and Handling:

- Damaged Buckets: Never store a damaged chain hoist; remove it from service immediately for repair.

- Proper Storage: Store the hoist in a dry, safe area away from harmful chemicals and corrosive environments.

Safe Storage and Handling of Chain Hoists

To ensure the lifespan and performance of a chain hoist, proper storage is essential. It should be kept dry, clean, and protected against corrosion. When storing the hoist, use the chain to suspend it by the upper suspension eye, keeping it off the ground. The chain can be coiled to facilitate storage and prevent damage. If the hoist is stored outdoors, make sure it is covered and protected against corrosion. Never drop, throw, or drag the hoist on the ground. Do not galvanize or apply any other coating process to the chain or load-bearing components without prior approval from the supplier.

Installation and Commissioning

Always follow the supplier's specific installation instructions and general guidelines. Test the winch to ensure it is working properly and the brake is effective. Make sure the chain is not twisted and can move freely. The lower hook should be able to reach its desired lowest position without fully extending the chain.

Uso Seguro de Talhas Manuais

- Never attempt a lifting operation unless you fully understand the equipment and lifting procedures.

- Do not use defective hoists, slings, or accessories and never use the lifting chain as a sling.

- Always inspect the lifting setup, making sure the hoist is securely mounted and that the chain is not twisted, especially in chain hoists with multiple branches.

- Before lifting, check if the load is free to move and if the support area is clear.

- Lift the load slightly, just enough to take it off the ground, and stop to check the integrity of the hoist and the lifting setup.

- Make sure the travel path is clear and maintain a clear line of sight to avoid accidental hook catches or collisions. Follow the specific safety rules of the site regarding the movement of suspended loads.

- When lowering a load, keep fingers, toes, and other body parts away.

Inspection and Maintenance

Follow the specific maintenance instructions from the supplier. Generally, be sure to regularly lubricate the load chain and check the brake operation. Keep the brake free of oil, grease, and contaminants. Never replace with a longer load chain without consulting the supplier. Periodically inspect the pulley for the following defects:

- Wear

- Damage to pulleys, hooks, and accessories

- Loose end anchor damaged or twisted

- Worn, bent, notched, stretched, corroded, or twisted chain that does not move freely

- Load slipping or failing to lift

- Damaged winch housing

- Illegible markings

Corrente de Carga Classe 80

The Class 80 load chain is a durable and high-strength chain, commonly used in lifting and hoisting applications. It is manufactured according to the EN 818-7 standard and designed for low-abrasion environments. This chain is ideal for low-speed manual and electric hoists.

- The lifting current should never be immersed in acidic solutions or exposed to acidic vapors.

- Make sure the lifting chain moves smoothly and without twists as it passes over the sprockets.

- To maximize the chain's lifespan, lubricate the lifting chain, especially in the contact areas between the links.

- Keep the chain clean, free of dirt and sand, to ensure proper operation.

Load Chain Specifications

- Finish: Black or galvanized oxide.

Especificações do Produto

| Reference | Size (mm) | Bitola (mm) | Minimum Internal Width (mm) | Maximum External Width (mm) | Length in 11 Steps (mm) | Working Load Limit (WLL) (kN) | Proof Strength (kN) | Minimum Breaking Load (kN) | Weight (kg/m) | Product Code |

|---|---|---|---|---|---|---|---|---|---|---|

| G8H0412 | 4 | 12 | 4.8 | 13.6 | 132 | 0.5 | 12.6 | 20.1 | 0.35 | 501020412 |

| G8H0515 | 5 | 15 | 6.0 | 17.0 | 165 | 0.8 | 19.6 | 31.4 | 0.55 | 501020515 |

| G8H0618 | 6 | 18 | 7.2 | 20.4 | 198 | 1.1 | 28.3 | 45.2 | 0.78 | 501020618 |

| G8H0721 | 7 | 21 | 8.4 | 23.8 | 231 | 1.5 | 38.5 | 61.6 | 1.06 | 501020721 |

| G8H0824 | 8 | 24 | 9.6 | – | – | – | – | – | – | – |

Brand: hqlifting

Product Details

Product 1: Model G8H0927

- Height: 7.2 cm

- Width: 264 cm

- Depth: 2 cm

- Peso: 50.3 kg

- Load capacity: 80.4 kg

- Engine power: 1.38 kW

- Número de série: 501020824

- Dimensions: 9 x 27 x 10.8 cm

- Velocidade nominal: 30.6 m/min

- Voltage: 297 V

- Corrente: 2.5 A

- Efficiency: 63.6%

- Temperatura: 102°C

- Fator de potência: 1.78

Produto 2: Modelo G8H1030

- Height: 10 cm

- Width: 30 cm

- Depth: 12.0 cm

- Peso: 34.0 kg

- Load capacity: 330 kg

- Engine power: 3.2 kW

- Número de série: 501020927

- Dimensions: 10 x 30 x 12.0 cm

- Velocidade nominal: 34.0 m/min

- Voltage: 330 V

- Corrente: 3.2 A

- Efficiency: 78.5%

- Temperatura: 126°C

- Fator de potência: 2.2

Product 3: Model G8H1030

- Height: 10 cm

- Width: 30 cm

- Depth: 12.0 cm

- Peso: 34.0 kg

- Load capacity: 330 kg

- Engine power: 3.2 kW

- Número de série: 501021030

- Dimensions: 10 x 30 x 12.0 cm

- Velocidade nominal: 34.0 m/min

- Voltage: 330 V

- Corrente: 3.2 A

- Efficiency: 78.5%

- Temperatura: 126°C

- Fator de potência: 2.2

Product Description

Na hqlifting, we offer a variety of high-quality equipment designed to meet your lifting needs. Our products are designed with durability and performance in mind, ensuring the highest possible efficiency and safety. Whether you are looking for reliable load capacity, ideal Motor Power, or energy-efficient performance, our product line offers the perfect solution. Choose hqlifting and experience cutting-edge lifting technology.

Reviews

There are no reviews yet.