Beam Clamp Type BC

Reference: 1501

The beam clamp, also known as the I-beam clamp or channel clamp, offers a simple and secure solution for connecting lifting equipment to beams. The main advantage of the adjustable beam clamp is the secure attachment to steel beams and I-beams, without the need for drilling or welding.

Main Features:

- Provides a stable anchor point for lifting and pulling tasks.

- This beam clamp is equipped with a spindle for quick and easy installation.

- Designed to accommodate a variety of beam widths.

- Can be quickly adjusted to fit most I-beams and H-beams.

- In compliance with Machinery Directive 2006/42/EC.

Palavras-chave:

beam clamp, beam clamp i, channel clamp, adjustable beam clamp, lifting beam clamp, fixing beam clamp

Specifications

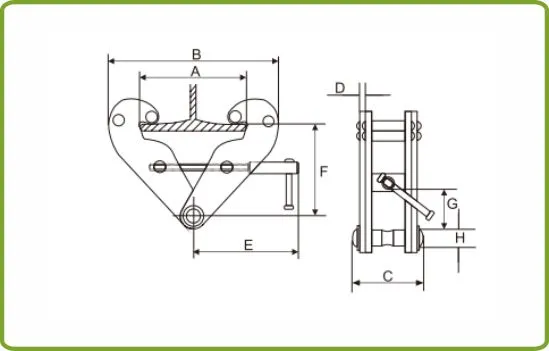

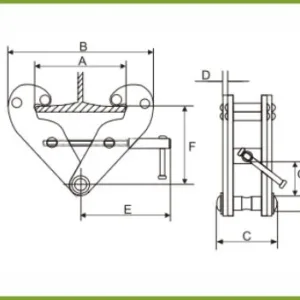

| Reference | Nominal Load (kN) | Test Load (kN) | Beam Width (mm) | Dimensions (mm) | Net Weight (kg) | Product Code |

|---|---|---|---|---|---|---|

| BC010 | 1 | 19.6 | 75-230 | A: 240mm; B: 192mm; C: 367mm; D: 94mm; E: 4mm; F: 194mm; G: 102mm; H: 154mm; t: 22mm; k: 20mm | 4 | 150101000 |

| BC020 | 2 | 39.2 | 75-230 | A: 240mm; B: 192mm; C: 367mm; D: 102mm; E: 6mm; F: 194mm; G: 102mm; H: 154mm; t: 22mm; k: 20mm | 4.8 | 150102000 |

| BC030 | 3 | 58.8 | 80-345 | A: 355mm; B: 243mm; C: 520mm; D: 132mm; E: 8mm; F: 241mm; G: 133mm; H: 223mm; t: 38mm; k: 22mm | 9.8 | 150103000 |

| BC050 | 5 | 98 | 80-345 | A: 355mm; B: 243mm; C: 520mm; D: 142mm; E: 10mm; F: 241mm; G: 133mm; H: 223mm; t: 35mm; k: 28mm | 11.6 | 150105000 |

| BC100 | 10 | 196 | 90-350 | A: 360mm; B: 272mm; C: 532mm; D: 180mm; E: 12mm; F: 284mm; G: 155mm; H: 234mm; t: 47mm; k: 38mm | 17 | 150110000 |

Related Products:

- Manual Chain Hoist, Type CH-B

- Permanent Lifting Magnet, Type PML

- Beam Clamp with Wide Mouth Shackle, Type BCL

- Scroll for Beam

Safe Use of Beam Clamps

When using beam clamps, it is important to ensure they are securely fastened and adjusted to the correct beam size. Usage must respect the nominal load capacity to ensure safety during lifting and pulling operations. Proper inspection and maintenance are essential to guarantee performance and safety.

Beam Clamp Safety Guide

Always follow the following safety measures:

- Store and handle the beam clamps with care.

- Inspect the beam clamps and accessories before each use and before storage.

- Make sure the support structure is capable of bearing the full load and suitable for the intended application.

- Check if the size and outline of the clamp are compatible with the beam and if it is properly installed on the beam flange.

- Check if the beam clamp's load capacity is sufficient to support the total load.

- Make sure the clamp is located directly above the center of gravity of the load.

The following is strictly prohibited:

- Never use beam clamps that are not marked or certified for lifting purposes.

- Never replace screws, shackles, or other components without consulting the supplier.

- Never throw or drop beam clamps.

- Never use beam clamps on damaged or deformed beams.

- Never force the lifting equipment hook on connection points or accessories (for example, shackles).

- Never load angle beam clamps without the supplier's approval.

How to select the appropriate beam clamp

Beam clamps vary in design and load capacity. These clamps can be adjustable or fixed, have scissor action, screw locking, or screw fastening mechanisms, and can be used for temporary or permanent applications. When selecting a beam clamp, consider the following factors:

- Types of clamp: adjustable or fixed; scissor type, screw or nut.

- The clamp's load capacity and the size or range of beam for which it is suitable.

- If the beam is capable of supporting the desired load.

- The type of lifting equipment that is being used.

- If the application is temporary or permanent.

Attention: Beam clamps are generally designed to be connected to a suspended beam for use as a suspension point for lifting equipment. Some designs may also be suitable for connection to a load to provide a lifting point. For applications that exceed standard use, it is essential to consult the supplier, as these may not be covered in common guidelines.

Proper storage and handling of beam clamps

Never store damaged beam clamps. They should always be kept dry, clean, and protected against corrosion. If necessary, the clamp fasteners must be reassembled immediately after removing the clamp from the beam.

Never drop or throw beam clamps.

Safe use of beam clamps

The safety in the use of beam clamps depends largely on the requirements of the lifting equipment used together.

- Never use beam clamps, lifting equipment, or defective accessories.

- Make sure that the structure to which the clamp is being suspended is in good condition and capable of supporting the full load. If in doubt, consult a qualified professional to confirm the suitability of the structure.

- Always check if the clamp is suitable for the application, if the size and contour are compatible with the beam, and if it is installed correctly.

Attention: The above information aims to guide the handling, storage, and safe use of beam clamps, ensuring efficient and safe lifting operations. Always follow the supplier's recommendations and applicable safety standards.

Beam Clamp Safety and Maintenance Guide

Compatibility and Use

When using beam clamps, ensure that the lifting equipment is compatible with the beam clamp. Hooks, shackles, or other accessories must be installed smoothly and without obstruction on the eye, shackle, or similar component of the beam clamp.

The beam clamp must be located directly over the load's center of gravity. Avoid load overhangs or the creation of angular loads that could cause instability or overload.

If two beam clamps are used together, additional equipment, such as a lifting bar, may be required to maintain balance and control. Always ensure that no individual beam clamp is subjected to a load exceeding its Safe Working Load (SWL).

Inspection and Periodic Maintenance

To maintain optimal performance, the beam clamps must be cleaned regularly and the moving parts must be lubricated as recommended by the manufacturer.

Complete inspections must be performed regularly. If any of the following issues are found, the beam clamp must be delivered to a qualified person for a detailed inspection:

- Wear, damage, or deformation

- Cracks

- Loose screws

- Corrosion

- Illegible identification

Proper maintenance and inspection are essential to ensure the safety and reliability of beam clamps in lifting operations.

Reviews

There are no reviews yet.