Need help? Write to us info@hqlifting.com

- Charging Accessories

- Lifting accessories

- Steel Cable

- Beam cart

- Turnstile for load securing

- Load Ratchet Strap

- Lifting current

- Chain for Load Lifting

- Lifting equipment

- Slings

- Steel Cable Tensioner

- Polyester slingshot

- Load binders

- STEEL HOOK

- Steel Cable Clamp

- Electric winch

- Permanent magnets

- Steel Cable Clamp

- moitão

- Carabiners

- Screw With Eyelet

- Lifting Clamp

- Talha Manual

- Uncategorized

Call our consultants or chat online

+86 151 4514 5178

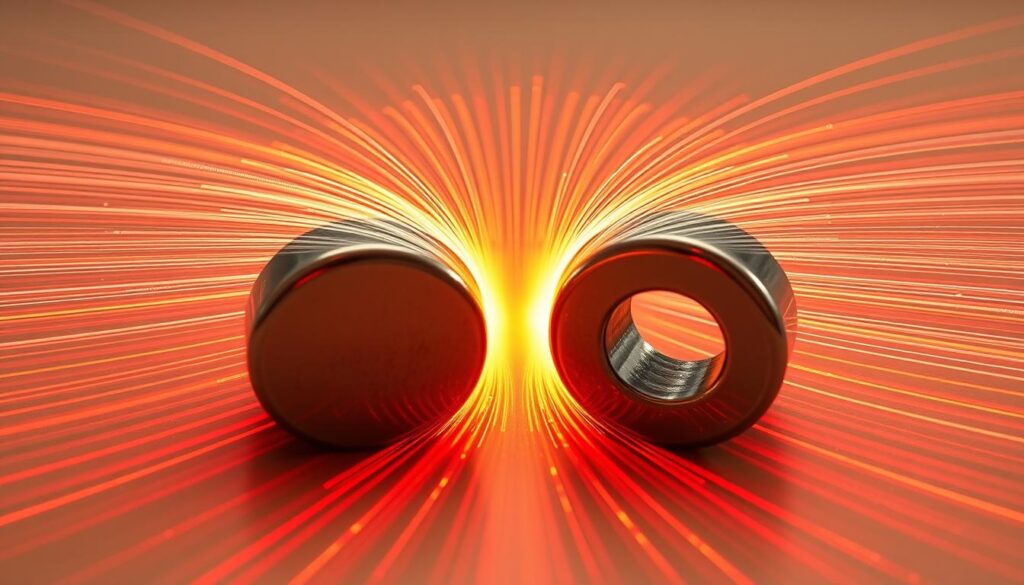

What Are Permanent Magnets? Understand Everything Here

Permanent magnets are materials that have magnetic force without needing energy. You find them in refrigerator magnets, headphones, and wireless chargers. They are essential for many modern technologies.

This article will explain how they work and their applications in everyday life. We will look at their history, types such as neodymium magnets, and how they are different from others. They are crucial in electronics, automobiles, and even in health. Get ready to discover the invisible world that moves us!

What Are Permanent Magnets: Definition and Basic Characteristics

Permanent magnets are materials that have natural or artificial magnetism. They create stable magnetic fields without needing external energy. Their operation is unique, different from other magnets. Learn more about their history and important characteristics:

The history of permanent magnets

The story begins with magnetite, used in Chinese compasses for millennia. In the 17th century, William Gilbert discovered that some minerals retained magnetism. In the 20th century, the invention of neodymium magnets changed technology.

Features that define a permanent magnet

- Maintains magnetism even without external power

- Has defined north and south poles

- Made of materials such as iron, nickel, cobalt, or metallic compounds

- Resistance to loss of magnetism at normal temperatures

Why are they called “permanents”

The term "permanent" means that they retain magnetism for decades. But it is not forever. Strong shocks, heat above 80°C, or opposing fields can reduce or erase the effect. However, in common use, its stability is guaranteed for a very long time.

Types of Permanent Magnets in the Market

Permanent magnets have different compositions and uses. See the main types:

- Ferrites (ceramics): They are cheap and do not react with moisture. They are used in electronics and motors.

- Alnico (aluminum, nickel, and cobalt): They resist heat well. They are great for industrial equipment.

- Samarium-Cobalt (SmCo): They maintain strength even at high temperatures. They are common in sensors and precise devices.

- Neodymium (NdFeB): They are the strongest. Made of neodymium, iron, and boron. They are essential in modern devices, such as headphones and wireless chargers.

| Type | Temperature Resistance | Common Applications | Custo |

|---|---|---|---|

| Ferrites | Average | Electronics, speakers | Low |

| Alnico | High | Musical instruments, engines | Medium |

| Samário-Cobalto | Very high | Automation systems, automobiles | High |

| Neodymium (NdFeB) | Median (up to 80°C) | Portable technology, chargers, electric vehicles | Médio-baixo |

Os NdFeB permanent magnets They are the strongest. But they need care with heat and corrosion. To choose the best, think about the use and the budget. Each material has its advantages for different needs of the United States market.

The Magnetic Field in Permanent Magnets

The magnetic field in permanent magnets comes from the organization of atoms. These materials have aligned magnetic moments, creating a stable external field. This naturally occurs in iron and neodymium, differentiating them from temporary magnets.

The field lines show the direction and intensity of the field. The closer they are, the greater the intensity, in Tesla (T) or Gauss (G). The strength decreases with distance, following the inverse square law.

How the magnetic field is formed

In permanent magnets, electrons in atoms create small fields. These fields permanently align, creating the magnet's overall field. This happens in materials like neodymium (NdFeB), known for high magnetic coercivity.

Line of force and intensity

- Density: Nearby lines indicate strong fields.

- Units: 1 Tesla = 10,000 Gauss.

- Decay: Intensity falls rapidly as it moves away from the magnet.

Interaction between magnetic fields

Opposite poles attract, while like poles repel. When two magnets come close, their fields either add up or cancel out depending on the orientation. This interaction explains why magnets stick together or move apart, a phenomenon crucial in industrial applications.

Differences between Permanent Magnets and Temporary Magnets

It is important to know the difference between permanent and temporary images to make the right choice. Permanent magnets maintain magnetism without needing external power. Temporary ones require an external field to work.

Features and composition of temporary magnets

Temporary magnets, made of soft iron or nickel alloys, lose magnetism quickly. They have a structure that allows atoms to easily realign with the external field. This makes them great for:

- Transformers

- Electric motors

- Relays and devices that require fast control

When to use each type of magnet

For situations that require constant magnetism, such as refrigerator magnets or permanent motors, prefer the permanent images. Already the temporary are perfect for:

- Systems that require quick shutdown

- Heat-sensitive equipment (e.g., household appliance motors)

- Lower costs in projects that do not require lasting magnetism

Choosing the right type depends on the project. Permanents are great for continuous use. Temporaries stand out in dynamic situations.

NdFeB Permanent Magnets: What They Are and Their Advantages

NdFeB permanent magnets are extremely powerful. They are made of neodymium, iron, boron, and other elements. This mixture creates very strong magnetic fields, up to 10 times stronger than common magnets.

- Extreme force: Perfect for applications that require high efficiency, such as electric motors and wind generators.

- Compacts: They are smaller but maintain the same strength as the larger ones, saving space.

- Versatile: They come in various formats, such as discs, blocks, and rings, meeting various industrial needs.

Although they are very efficient, NdFeB magnets have limitations. They can corrode and lose strength above 80°C. To solve this, the Magforce uses nickel or epoxy coatings. This protects the material and allows its use in humid climates or hot environments.

In the United States, these magnets are very important in various sectors. For example:

- Automotive industry (electric cars)

- Electronics (hard drives and speakers)

- Health (magnetic resonance)

A survey by ABIMAG It showed that 70-73% of the new industrial equipment in the United States use NdFeB. This is due to its cost-effectiveness. Currently, there is research to create even stronger alloys. Thus, NdFeB magnets will continue to lead technological innovations.

What Is the Relationship Between Domains and Permanent Magnets

To understand permanent magnets, we must talk about the magnetic domains. These microscopic areas have atoms that naturally align. They are like thousands of "mini-magnets" in a piece of iron.

What are magnetic domains?

Domains are areas where atoms organize in a common direction. In non-magnetized materials, these areas point randomly. When magnetized, the domains align, creating the magnetic force of permanent magnets.

How do domains influence magnetic strength?

- Total alignment: strong magnets have domains almost all in the same direction

- Materials such as NdFeB (discussed in section 6) have a crystal structure that facilitates alignment

- Misalignment causes loss of power (e.g., when overheating)

Viewing domains in different materials

| Material | Domain Behavior | Visualization Technique |

|---|---|---|

| Ferro | Large and easily alignable domains | Atomic force microscopy |

| NdFeB | Microscopic domains with high coherence | Analysis by Kerr effect |

| Aluminum | Missing domains – non-magnetic | Does not require preview |

This molecular organization explains the high performance of permanent magnets. The relationship between domains and material structure affects the strength and durability of the magnet.

Industrial and Commercial Applications of Fixed Permanent Magnets

Fixed permanent magnets are key components in innovations driving essential sectors in the United States. Their uses range from heavy industries to everyday solutions, ensuring efficiency and safety.

In the industrial sector, these magnets are essential in:

- Separation systems in mining and recycling, precisely removing ferrous metals;

- Electric motors for industrial equipment, reducing energy consumption;

- Assembly of production lines, securing components without the need for continuous power;

- Sensors in automatic machines, controlling manufacturing processes.

In commerce, applications such as:

- Magnetic catches on furniture and store doors;

- Tool holders in supermarkets;

- Anti-theft systems in retail;

- Components of medical equipment, such as diagnostic devices.

Their benefits, such as durability and independence from external power sources, make them ideal for operations in harsh environments. In the United States, companies such as Magforce e Imantech already adopt these technologies in green energy and logistics projects. Local research in magnet nanotechnology also paves the way for future applications in electric vehicles and medical devices. These magnets enable practical and sustainable solutions, reinforcing their importance in the United States market.

How an Electromagnet Works on an Elevator Door

Elevator automatic doors use precise systems to be safe and efficient. The electromagnet is essential for this operation. Let's explore how the elevator door electromagnet works and its applications.

Differences between permanent magnets and electromagnets

| Feature | Permanent Magnet | Electromagnet |

|---|---|---|

| Magnetic Field | Permanent | Activated by electric current |

| Control | Uncontrollable | Controlled by switches |

| Energy | Does not consume energy | Requires electric power |

Elevator door mechanism

The electromagnet is located at the top of the door. With the electric current, it pulls a metal plate, closing the door. Without current, the door opens. Safety sensors and electronic control make everything work well.

System advantages

- Safety: In case of a power outage, the doors may remain open or closed.

- Smooth operation: There is no mechanical friction.

- Less wear: With fewer moving parts, maintenance decreases.

- Smart integration: Works well with modern automation systems.

In the United States, brands like Schindler and OTIS have created more energy-efficient versions.

Care and Maintenance of Permanent Magnets

Os what are fixed permanent magnets need special care. High temperatures can damage the magnets. Check the Curie temperature, which indicates when the magnet loses its strength.

For neodymium magnets, it is important to avoid humid environments. This helps prevent corrosion.

- Thermal protection: Store away from heat sources. NdFeB magnets lose strength above 80°C.

- Avoid impacts: Strong shocks misaligned magnetic domains, reducing strength. Use rigid packaging during transport.

- Proper storage:

- Use stainless steel “keepers” in large magnets to maintain alignment.

- Safe cleaning: Use a damp cloth and neutral soap. Avoid chemical solvents on coated surfaces.

- Periodic inspection: Test the adhesion in critical applications (such as engines) every 6 months.

If there are cracks or loss of grip, replace immediately. Following these tips maintains the durability and safety of the equipment. Small maintenance adjustments prevent costly technical failures.

Conclusion

Permanent magnets are essential in many sectors, such as electronics and transportation. They work thanks to internal magnetization and aligned domains. This differentiates them from temporary magnets.

Materials like neodymium are efficient but face limitations. This motivates the search for sustainable alternatives.

In practice, permanent magnets are used in elevator doors and wind generators. They ensure safety and efficiency. In the United States, choosing the right magnet is crucial for industries.

Properly maintaining the magnets prevents loss of strength. This increases the lifespan of the devices.

The future promises more durable materials and green technologies. Understand what are permanent magnets It is essential to invest in innovations. These components are essential for modern infrastructure.

They are essential for a cleaner and more efficient world.

Share:

June Han /founder and designer

The co-founder of Hqlifting, sales director, amateur writer about fitness business