Need help? Write to us info@hqlifting.com

- Charging Accessories

- Lifting accessories

- Steel Cable

- Beam cart

- Turnstile for load securing

- Load Ratchet Strap

- Lifting current

- Chain for Load Lifting

- Lifting equipment

- Slings

- Steel Cable Tensioner

- Polyester slingshot

- Load binders

- STEEL HOOK

- Steel Cable Clamp

- Electric winch

- Permanent magnets

- Steel Cable Clamp

- moitão

- Carabiners

- Screw With Eyelet

- Lifting Clamp

- Talha Manual

- Uncategorized

Call our consultants or chat online

+86 151 4514 5178

Clamp for Steel Cable: Certified Fixing Techniques

Wire rope clips are very important in industrial lifting systems. They directly affect the safety and structure of the loads. Therefore, it is essential to choose and apply them carefully.

To properly secure clamps, it is necessary to know about diameters, gauges, and the maximum weight they can support. Errors can reduce the cable's strength by up to 30%. This is a warning from the Brazilian Industrial Cabling Association.

For professionals, the wire rope clip is much more than an accessory. It is a key component between the design and the operation. Proper fastening involves calculating the safety factor, positioning correctly, and applying the right torque. This follows the rules of manufacturers like Crosby or Miller.

What is a Wire Rope Clip and Its Importance in Safety

Wire rope clips are devices made of metal. They connect cable terminals, keeping everything secure. They are essential in lifting installations, linking machines and loads. The standard for wire rope clips sets rules for safety and compliance.

Function of clamps in lifting systems

The staples have three important functions:

- ✅ Distribute radial and axial loads, preventing clamp failures for steel cable due to overload;

- ✅ Ensure axial alignment of the cable during repetitive movements;

- ✅ They protect the inner surface of the cable against deformation from excessive pressure.

Why the correct choice of clamps is crucial

Choosing the wrong staples can be dangerous:

| Parameter | Technical specification |

|---|---|

| Cable diameter | Must match the clamp gauge (e.g., 6×19 mm) |

| Nominal load | It must be 120% of the maximum applied load |

| Material | Carbon steel or stainless steel according to ABNT NBR 12345 standard (example of technical standard) |

Risks of improper fixation

Errors in fastening clamps for steel cable can cause:

- Sudden failures in critical loads;

- Accelerated wear of the cable structure;

- Compromise of the system's technical certification.

Following the standard for wire rope clamps is essential. This is not only legal but also ensures safety at work. Failures in wire rope clamps can lead to accidents, affecting productivity and team safety. Proper fastening prevents these problems and maintains compliance with technical standards.

Main Types of Steel Cable Clamps Available on the Market

To ensure safety and efficiency, it is important to know the technical models recommended by ABNT NBR 12,826. Each type is designed to meet specific load and operating environment needs.

U-type Clamps (Drop Forged)

✅ Os clamp or for steel cable They are made by cold forging. They have a strength of up to 200 MPa. Their U-shape allows attachment to cables with diameters from 3 to 50 mm. They are ideal for applications with dynamic loads over 5 tons.

Clip-type clamps

- Cable clamp clip with automatic lock for quick fastenings

- Compatible with cables from 1/8″ to 1/2″

- Clamp clips for steel cable reduce installation time in 40% compared to conventional models

Light clamps vs. heavy clamps

A light clamp designation for steel cable handles loads up to 2.5 tons. As for the heavy clamp for steel cable Supports up to 20 tons. The difference in sheet thickness (2.5mm vs 6mm) defines the ABNT safety rating.

Stainless steel clamps

For maritime or chemical applications, the stainless steel clamp for 1 8 cable and similar comply with ASTM A240 standard. A difference between clamp and clip for steel cable includes special heat treatment for temperatures up to 600°C.

Sizes and Gauges: Understanding the Measurements of Clamps for Steel Cables

To ensure safety and efficiency in lifting systems, the precise measurement of clamps is essential. The dimensions of clamps for steel cable are directly related to the cable gauge. The base height, bridge width, and screw diameter must exactly match the technical specifications.

- Use certified parking meters to measure the cable diameter;

- Consult the correspondence tables provided by the manufacturers;

- Check the conversion between inches and millimeters to avoid errors;

- Compare the clamp's load capacity with the project's demand.

| Bitola to Cape (mm/inches) | Base Height (mm) | Bridge Width (mm) | Screw Diameter (mm) | Load Capacity (kN) |

|---|---|---|---|---|

| 3.175 mm (1/8″) | 10 mm | 15 mm | M8 | 2.5 kN |

| 3.969 mm (3/16″) | 12 mm | 18 mm | M10 | 4.0 kN |

| 6.35 mm (1/4″) | 16 mm | 25 mm | M12 | 6.5 kN |

| 8.0 mm (5/16″) | 19 mm | 30 mm | M14 | 8.0 kN |

| 9.525 mm (3/8″) | 22 mm | 35 mm | M16 | 10 kN |

✅ Always use precision tools to avoid deviations. The table above illustrates examples of matching between gauges and clamp dimensions. For cables 1/2″ or larger, consult the manufacturer's technical specifications. Improper size selection can reduce equipment lifespan and compromise safety.

- Avoid visual measurements: use calipers or micrometers;

- Confirm compatibility with NBR or ISO standards;

- Store the gauges in the project's technical records.

The periodic calibration of measuring tools ensures the integrity of the dimensions of wire rope clamps. Product certification is essential for safe operations in compliance with technical standards.

How to Choose the Ideal Clamp for Your Project

Choosing the right clamp is a technical process. The matching table between cable and clamp (clamp for steel cable table) helps to find compatibility. A NBR 12,100 establishes standards for safety and legal compliance.

| Cable (inches) | Recommended clamp | Material |

|---|---|---|

| 1/8 to 3/16 | Specification of 1/2 clamp for steel cable | Galvanized carbon steel |

| 5/16 to 1/2 | 5/16 Clamp for stainless steel wire rope | 316 stainless steel |

| 3/4+ | U-type clamps with larger gauge | Alloy 4140 with heat treatment |

Workload of clamps for steel cables must follow the NBR safety factor. For common applications, it is 5:1. In critical areas, it is 10:1. To choose the clamp, consider:

- Check the WLL (Working Load Limit) of the clamp vs. the project's nominal load

- Validate certifications such as nbr clamps for steel cables

In corrosive environments, prefer stainless steel clamps. For example, the 5/16 clamp for stainless steel wire rope. Avoid mixing metals that may cause galvanic corrosion. The 1/2 clamp for steel cable must have:

- Nominal cable diameter ± 5% of the clamp gauge

- Pre-installation tensile tests

Professionals should choose clamps certified by ABNT. This ensures mechanical strength and compliance with technical standards. The final choice depends on the analysis of size, load, and operating environment.

How to Properly Attach a Clamp to Secure a Steel Cable

To secure a clamp to fasten a steel cable safely, follow technical protocols validated by industrial standards. Proper clamp positioning prevents structural failures and ensures the integrity of the connections. ✅

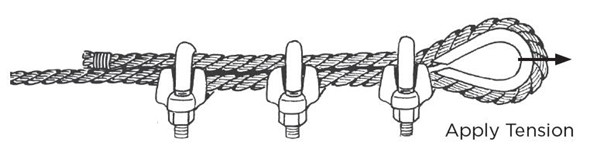

Correct positioning of the clamp on the cable

The principle "Never Saddle a Dead Horse" is essential: the U-shaped base of the clamp must be on the active side of the cable (subject to tension), while the flat part (cap) is positioned on the dead side. This alignment distributes loads according to NBR 14.333.

Ideal spacing between staples

- minimum spacing of clamp for steel cable: 6x the cable diameter between consecutive fastenings

- For 8mm cables, the spacing between clamps for steel cable must be ≥48mm

- For dynamic loads, reduce the spacing in 20% according to ABNT guidelines

Proper torque for tightening screws

Use the key for steel cable clamp with torque specified in the table:

| Bitola (mm) | Torque value (Nm) |

|---|---|

| 6,35 | 25 |

| 9,52 | 45 |

| 12,70 | 75 |

Under-tightening will reduce fastening, while over-tightening will cause deformation. Use torque wrenches calibrated annually.

Tools needed for installation

Essential equipment:

- Adjustable wrench for hexagonal screws

- Digital torque meter (NBR 12,991 certification)

- Graphic lubricant for thread (torque separator)

- Laser level for angular alignment (optional in critical applications)

The minimum length for clamping steel cable must comply with the manufacturer's correspondence table, avoiding fixing clamps on steel cable in bending areas.

Technical Standards and Certifications for Steel Cable Clamps in the United States

Os abnt clamps for steel cable must follow the ABNT standards. NBR 13541 is one of them, which defines how to fix correctly. A correct fixation involves safety, maximum load, and appropriate size.

✅ Essential rules:

- NBR 13541: defines parameters for the manufacturing and testing of clamps;

- NBR 15721: talks about tensile and fatigue tests;

- NR 16: deals with safety in lifting equipment.

Os steel cable clamp tests include tensile and fatigue tests. They also measure torque. No steel cable clamp tests youtube, there are certified technical videos. The ncm clamp for steel cable It is fiscally classified as 7317.99.90, important for imports and exports. A tax classification clamp for steel cable assistance with customs and tax compliance.

Products certified by ABNT have marks such as CE ou Inmetro. They show load capacity and manufacturing batch. Avoid using clamps without certification abnt clamps for steel cable correct fastening to avoid structural problems.

For safe operations, check:

- Manufacturer certifications;

- Test documentation;

- Correct NCM classification.

Specific Applications for Different Clamp Sizes

Clamps must be chosen carefully for each use. Each size has its capabilities, from light projects to major structures. It is crucial to have a load chart to avoid problems.

Clamp for 1/8 and 3/16 Steel Cable: Light and Non-Structural Projects

The 1/8″ (3mm) and 3/16″ (5mm) staples support up to 240kg. ✅ They are perfect for:

- Install lighting fixtures and signage in industrial locations

- Hold light equipment, such as sensors and valves

- Temporarily use in non-essential assemblies

Clamp for 1/4 and 5/16 steel cable: Intermediate Systems

The 1/4″ (6mm) and 5/16″ (8mm) clamps support from 340kg to 680kg. They are used in:

- Construction of bracing systems

- Install electric fences and solar panels

- Build medium-strength metal structures

Clamp for 3/8 and 1/2 steel cable: Heavy Lifting

To load from 1,000kg to 2,200kg, the 3/8″ (10mm) and 1/2″ (13mm) clamps are crucial in:

- Use in cranes and to lift heavy parts

- Holding at port facilities

- Focus on industrial equipment

Large Clamps (5/8″, 3/4″ and 1″)

To load more than 3,500kg, 5/8″ (16mm), 3/4″ (19mm), and 1″ (25mm) clamps are essential in:

- Build cable-stayed bridges and viaducts

- High-performance lifting platforms

- Fix on offshore platforms

For critical situations, check certifications such as ISO 13948 and ABNT NBR 16.220 standards. Choosing the wrong clamp can be dangerous, requiring technical attention.

Common Errors in Clamp Installation and How to Avoid Them

Errors in fastening clamps for steel cable can be dangerous. They affect the safety and efficiency of the system. See what the common errors are and how to avoid them:

Base and clamp cover inversion

A difference between clips for steel cable clamp and U-type models is important. Reversing the parts reduces the load capacity in 80%. The clip clamp for 8 mm steel cable It needs to be assembled correctly to work well. Check the "TOP" or "BASE" marks before fixing.

Insufficient number of staples

It is essential to calculate the minimum number of clamps. The clamp clips for steel cable fastening are discounted if the distance between them is greater than 1.5x the cable diameter. For scales, use the formula: N = (Cable length / 3D) + 1, where D is the cable diameter. Using fewer clamps than necessary increases the risk of slipping.

Incorrect screw adjustment

An inadequate torque can damage the cable. For the clip clamp for steel cable brand certified, follow the recommended values:

- Subaperto (

- Overtightening (> 120% torque: clamp structure deformation.

✅ Useclamp clips for steel cable are discountedaccording to the table provided by the manufacturer.

Maintenance and Inspection of Steel Cable Clamps

✅ Keeping the clamps up to date is crucial for connection safety. It gives tips to detect damage. It is important to visually inspect before use, looking for signs of wear or lack of adjustment.

- Daily visual inspection: check for cracks and surface wear

- Torque measurement with a torque wrench according to the

- Application of anti-corrosion lubricants in areas exposed to humid environments

See the scheduled inspection table:

| Ambiente | Inspection frequency |

|---|---|

| Indoorense (dry) | Weekly + detailed quarterly |

| Maritime/industrial | Bimonthly + monthly with tensile tests |

It requires photos during the inspection. It helps you simulate wear. Replace immediately if:

- Deformation greater than 5% of the cross section

- Loss of 20% of nominal traction

Consult the for technical details. The ensures compliance with standards. Do not discard parts with wear greater than 10% — immediate replacement is essential.

Where to Buy Quality Steel Cable Clamps

It is very important to choose certified clamps to ensure quality. Companies in Porto Alegre and Serrano have options such as clamp clip for 1/8 steel cable e clips clamp 10mm. They also offer DWG files for projects, which is very useful.

Reliable suppliers in the United States

- Companies certified ISO 9001 and ABNT NBR 16208 are in Porto Alegre and Serrano. They sell since flat clamp for steel cable até connector clamp type clamp 5-inch para.

- Check if the clamp 20 has CE and NR 16 markings. It is also important that the clips clamp press have precise dimensions, such as 13mm.

What to check before buying

✅ O Clamp clips for 10mm steel cable must have CE and NR 16 markings. It is essential that the load tests and specifications, such as the 5 inch clamp clip, be well documented. To know the reference of the clamp 20, see the gauge correspondence tables.

Cost-benefit ratio x safety

Choose cheaper options, such as connector for clamp-type steel cable, can compromise safety. Studies show that errors in clamp for 1/8 steel cable cause problems in 42% of the cases. Therefore, prefer brands with technical warranty and after-sales support.

Frequently Asked Questions About Steel Cable Clamps

Clarify critical technical doubts to ensure compliance and safety in lifting projects. Check the answers based on NBR and ABNT standards:

✅ How to correctly measure a clamp for steel cable?

For fastening clamps such as the 6 00000 clamp for 04mm or 08mm steel cable, check:

- Internal diameter of the U base: must match the nominal diameter of the cable (e.g., 6 00000 04mm for 4mm cables)

- Bridge width and plate thickness

- Diameter of screws and threading length

Avoid approximate measurements – errors can reduce up to 30% of the load capacity.

✅ What is the difference between a light clamp and a heavy clamp?

O light clamp for steel cable (light clamp designation) is designed for loads up to 50% of the maximum capacity. As for the heavy clamp for steel cable (Ex: heavy 3/8 steel cable clamp) uses high-toughness steels and larger thicknesses 20-30%. The NBR 16225 table defines different technical specifications for each type.

✅ How many staples to use?

Calculate with the formula: N = (Total_load) / (Load_allowed_per_clamp * 0.85). Example:

- 3/8″ cable: use heavy 3/8 clamp with a minimum of 2 units per connection

- Thin wire (04mm): 1 light clamp 04mm every 15cm

Following supplier tables like those in catalog 6 00000 is essential.

✅ Is it safe to reuse staples?

NBR 16225 prohibits the reuse of fastening clamps after dynamic loads. Microscopic deformations in the bridge area and thread wear compromise safety. Clamps like 6 00000 08mm must be discarded after use in critical applications.

Conclusion

Choosing and installing wire rope clips according to ABNT standards is crucial. This ensures structural safety. Certified clips reduce the risk of failures, from light to heavy.

Following ABNT means that the clamps meet load and durability criteria. This is vital to avoid problems in lifting systems.

For critical situations, it is important to choose manufacturers with technical certifications. Using clamps improperly can cause serious failures, especially in locations with constant movement. The choice between clamps for heavy cables or stainless steel depends on the environment and technical needs.

Professionals should choose clamps from reliable brands. Checking diameters and maximum loads is essential. Regularly maintaining and inspecting these clamps helps prevent premature wear.

Using staples according to ABNT standards is a commitment to safety. This protects both people and structures.

⚠️ Always compare the specifications with the official tables. Avoid making substitutions without authorization. The correct application of certified clamps ensures legal compliance and system durability.

Share:

June Han /founder and designer

The co-founder of Hqlifting, sales director, amateur writer about fitness business