Need help? Write to us info@hqlifting.com

- Charging Accessories

- Lifting accessories

- Steel Cable

- Beam cart

- Turnstile for load securing

- Load Ratchet Strap

- Lifting current

- Chain for Load Lifting

- Lifting equipment

- Slings

- Steel Cable Tensioner

- Polyester slingshot

- Load binders

- STEEL HOOK

- Steel Cable Clamp

- Electric winch

- Permanent magnets

- Steel Cable Clamp

- moitão

- Carabiners

- Screw With Eyelet

- Lifting Clamp

- Talha Manual

- Uncategorized

Call our consultants or chat online

+86 151 4514 5178

Understand How the Ratchet Strap Works in Detail

Transporting cargo safely is essential to protect the goods and comply with the laws. A ratchet belt It is the best option for securing loads. But, many people still do not know how does a ratchet strap workThis article will explain how it works, so that you and your company can transport more safely.

Pontos-chave

- Detailed explanation of the locking and fastening mechanism.

- Understand the importance of loads with different weights and dimensions.

- Learn how to choose the appropriate strap thickness according to the load.

- Learn about the safety standards required in the United States for cargo transportation.

- Practical tips to avoid damage and increase the durability of straps.

What is a Ratchet Strap and What is it Used For

A ratchet strap is a device for securing loads on trucks, warehouses, and industries. It works with an elastic strap and a locking mechanism. This prevents the load from slipping. This combination provides safety and convenience for logistics operations.

History and evolution of ratchet straps

The first ratchet belts appeared in the 1950s. They were made of simple materials, such as ropes with basic levers. In the 1980s, they began using steel and reinforced plastics to increase durability.

Today, modern models, like those from Wonder, use high-density polymers and automatic locks. This makes the straps essential for modern transportation.

Main advantages compared to other tie-down systems

- Ease of adjustment: there is no need to recalculate distances like in traditional ropes.

- Enhanced security: Mechanical locks prevent slipping, unlike common elastics.

- Variable capacity: can support loads from 1 to 5 tons, adapting to different sectors.

Types of ratchet straps available in the United States market

| Type | Common Use | Maximum Capacity |

|---|---|---|

| Light Belt | Small goods (furniture, appliances) | Up to 1.5 tons |

| Medium Belt | Medium loads (pallets, tools) | 2 to 3 tons |

| Heavy Tape | Industrial loads (machines, steels) | Up to 5 tons |

Marcar, CargoFix, and SecureTie offer models for every type. They have ANTT certifications for road transport in the United States.

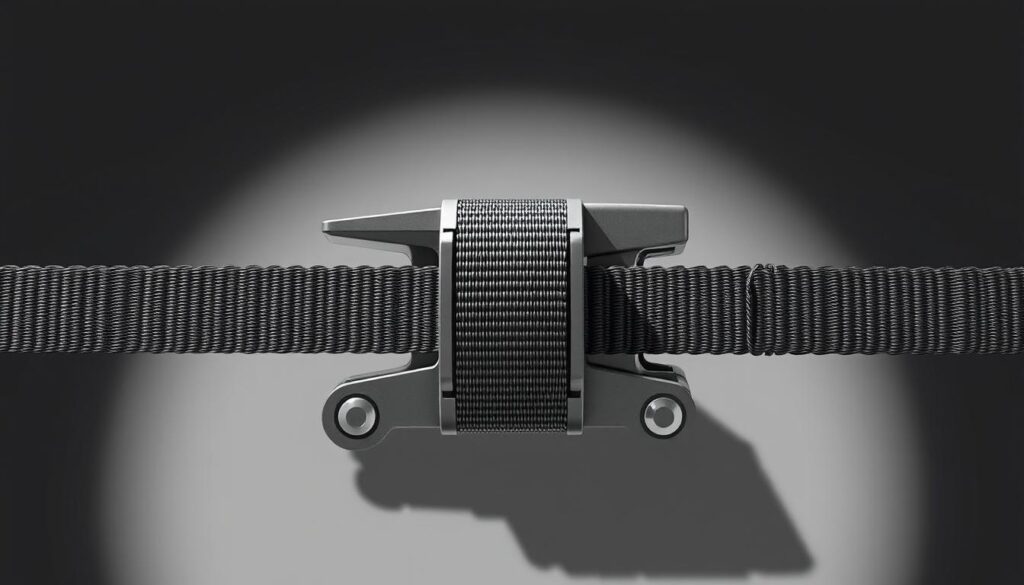

Essential Components of the Ratchet Strap

To know how does a ratchet belt work, it is important to know its components. Each part works together to ensure safety and efficiency. Let's look at the main elements:

- Polyester or nylon tape: It is the main body. It distributes the force. Materials such as reinforced polyester or treated nylon are used to last longer;

- Ratchet mechanism: automatically adjusts the belt tension;

- Metal hooks: They are the fastening terminals. Usually made of galvanized steel, they adapt to various surfaces;

- Safety lock: prevents the strap from coming loose accidentally;

- Adjustment lever: It is what the user uses to tighten or release the strap.

The chosen materials greatly affect performance. For example, Wonder straps use polyester with a scratch-resistant coating. Industrial models have hooks treated against corrosion. The how does a ratchet belt work It is because of the interaction between these elements. The ratchet compacts the strap, the lock maintains the pressure, and the hooks distribute the load evenly.

The variations, such as the tape width (from 25mm to 50mm) or the shape of the hooks, depend on the use. Even with new features, the basic principles of the components remain the same. This ensures they comply with standards, such as NR-16.

How Ratchet Strap Works: The Mechanism Explained

The ratchet strap works with physical principles and practical design. Let's see how each part helps with safety and efficiency.

The principle of the lever applied in ratchets

The lever makes it easier to tension the strap. By pulling the lever, the force increases. Thus, the user can adjust the strap without excessive effort.

Operation of the locking system

The system uses interlocking teeth and a spring to maintain tension. When the lever is released, the teeth engage, preventing slipping. The spring maintains pressure to avoid accidental release.

What is the ideal ratchet strap thickness for different loads

The thickness of the belt defines its strength. See the recommendations:

- Light loads (up to 500 kg): 25 mm ribbons, ideal for small or fragile objects.

- Medium loads (500-2000 kg): 35 mm, to support greater weights without deformation.

- Heavy loads (over 2000 kg): 50 mm or more, ensuring rigidity in industrial transportation.

Choosing the wrong thickness can reduce safety. Always check the strap's capacity before use.

Step by Step: How to Use a Ratchet Strap Correctly

To use ratchet straps safely and efficiently, follow these steps. The how does a ratchet strap work It depends on the technique. This goes from preparation to final release.

Load preparation for lashing

- Evaluate the load's center of gravity to distribute the weight evenly.

- Protect sharp corners or edges with foam or protective plates.

- Choose solid fixed points, such as hooks or perforations on the truck chassis.

Correct positioning of the belt

Position the strap at a right angle between the load and the fastener. Distribute the ties at opposite points for balance. Avoid twists in the strap: it should be aligned with the movement of the load.

Technique for tightening without damaging

- Pull the lever with smooth motion, avoiding sudden forces.

- Check the tension with your hand: the strap should be tight, but not stretched to the extreme.

- Repeat the process in all positions to even out the pressure.

How to safely release the strap

To release, press the unlock button while holding the lever. Release slowly to avoid the "whip effect." Never force the tape if it jams: check the mechanism before reloading.

O how does a ratchet strap work includes these practical details. They ensure durability and compliance with transportation regulations, such as NR-16.

Practical Applications: Where and How to Use Ratchet Straps

Ratchet straps are essential to ensure safety in various areas. They adapt to different needs, from heavy transportation to everyday applications.

In road transport, they are ideal for securing loads on trucks. This prevents movement during the trip. In ports and ships, they help stabilize containers and vessels. In construction, tying equipment such as scaffolding or blocks is crucial to avoid accidents.

| Sector | Main Applications | Quick Tips |

|---|---|---|

| Road Transport | Loads on trucks, trailers, and utility vehicles | Use 2-4 tapes per load, depending on the weight. |

| Maritime Transport | Fastening on containers and vessels | Adjust the tension to absorb sea swells. |

| Civil Construction | Fragile or heavy materials | Evaluate strong attachment points on the load. |

| Residential Changes | Furniture and appliances in moving trucks | Avoid direct pressure on delicate surfaces. |

| Industry | Internal machinery transportation | Periodically check the integrity of the strap. |

| Lazer | Motorcycles, ATVs, and sports equipment | Adjust according to the cargo vehicle format. |

Do not use on loads sensitive to intense pressure, such as thin glass or fragile objects. For the how does a load strap ratchet work, always prioritize the uniform distribution of the straps. Assess the type of load beforehand. Following these guidelines ensures greater efficiency and safety in all applications.

How Tape Turnstile for Truck Load Works

A belt turnstile It is crucial to transport loads safely in trucks. It is important to know the rules and techniques to comply with the law and protect the cargo.

Legal requirements for cargo transportation in the United States

Laws such as CONTRAN Resolution 633/2016 and ABNT NBR 11.200 standards require proper securing of loads. Violations can result in fines of up to R$ 293.47. Additionally, there are risks of accidents. Always check the requirements before loading.

Distribution of tie-down points for greater safety

- Position tie-off points at angles of 45° to 90° relative to the load;

- Use the fixed anchor points of the trucks (e.g., side and rear hooks);

- For heavy loads, add diagonal straps to prevent tipping;

Calculation of how many straps are needed per type of load

The number of straps varies according to the weight and shape of the load. Calculate:

- Total weight: use 1 strap for every 200 kg;

- Bulky loads (such as coils) require at least 4 fastening points;

- For fragile loads (such as glass), add insulation and extra straps;

Example: transport of 3 tons of heavy equipment: 15 straps distributed in 4 directions. Consult specific ABNT technical tables to adjust the quantities.

Specifics of the Wonder Ratchet Strap

The Wonder ratchet strap is famous for its technology and reliability. It was designed to handle heavy loads. Its technical features ensure exceptional performance in various sectors.

Technical Differentials of the Wonder Brand

- High-strength polyester material with Kevlar reinforcement, reducing risk of tearing;

- Patented anti-return system that blocks involuntary movements during transport;

- Ratchets with self-adjusting hooks, compliant with ISO 17088 and ABNT NBR 16225 standards;

- Line with a load capacity from 2,500kg to 8,000kg, meeting specific industrial demands;

- 5-year warranty against manufacturing defects.

Practical applications of the Wonder ratchet strap

In heavy machinery movement, the Wonder strap holds well on difficult terrain. For transporting wood, the nail technology prevents the load from shifting. In the automotive sector, the quick version ties in 30 seconds.

In humid places, the TPU treatment keeps the strap rigid. The Wonder ratchet mechanism adjusts up to 20% more tension. This causes the how does the wonder ratchet strap work be perfect for demanding operations, without safety risks.

Maintenance and Care Tips

To make your ratchet strap last longer, follow some simple tips. Keeping the strap in good condition prevents problems and ensures safety. See how to take care of your strap with these important tips:

- Cleaning: Use a damp cloth with neutral soap to remove dirt. Do not use chemicals that may damage the strap.

- Drying: Let the belt dry in a cool place. Do not leave it exposed to the sun to avoid it drying out.

- Lubrication: Choose specific oil for metal mechanisms. This helps keep the movement smooth and dust-free.

- Storage: Roll the tape onto a rigid spool. Store on a dry shelf, away from moisture and rust.

Before using the strap, do a quick check. Look for loose threads, cracks, or wear on the ratchet. If you find any damage, replace the strap immediately. In areas near the sea, wash the strap with fresh water to remove the salt. If the area is very dusty, clean the ratchet with a soft brush to prevent it from getting clogged.

To load wet items, dry the strap before storing it. Doing a quick checklist helps a lot. Check if the ratchet is aligned, if the strap is intact, and if the locking system is working well. Following these basic precautions ensures that the strap lasts longer and meets safety standards.

Common Problems and How to Solve Them

Understanding how a ratchet seatbelt works means knowing how to identify common faults. Several factors can affect its performance. But most problems have practical solutions. See a step-by-step guide for each situation:

When the ratchet locks or jams

- Causes: Dust, rust, or materials stuck in the mechanism

- Solution: Clean with a dry cloth and lubricate with oil specific for gears. Avoid products with harsh solvents.

Belt wear: when to replace

Critical indicators include:

- Fraying greater than 2cm

- Cross sections in the fiber

- Whitening or abnormal stiffness

Lifespan guide:

- Daily use: 6-12 months

- Weekly operation: 2-3 years

- Storage: replace after 5 years, even if unused

Emergency repairs and precautions

- For small cracks: Use reinforced adhesive tape temporarily

- Strap stuck under load: Cut only if there is a risk of damage to the load. Always release the mechanism before removing.

Never use straps with permanent structural damage. Prioritize replacement when in doubt to ensure safety during transport.

Conclusion

Understanding how the ratchet strap works and choosing the right thickness is essential for load safety. In this article, we explore from the start of the lever to the importance of the Wonder brand. The thickness of the strap affects the strength, especially in heavy loads.

The correct use of the Wonder ratchet strap and other models is crucial. This includes positioning, tensioning, and regular maintenance. Safety in transportation is not just a standard, but a responsibility to everyone.

If you choose Wonder belts, follow the usage instructions and regularly check for signs of wear. Choosing qualified products and proper techniques reduces risks and costs related to accidents. Share your experiences or questions to improve safety in logistics.

Investing in equipment like ratchet straps is investing in life. By following the tips in this guide, you help make the roads safer. Stay updated on standards and technologies, like those from Wonder, to always prioritize safety.

Share:

June Han /founder and designer

The co-founder of Hqlifting, sales director, amateur writer about fitness business