Need help? Write to us info@hqlifting.com

- Charging Accessories

- Lifting accessories

- Steel Cable

- Beam cart

- Turnstile for load securing

- Load Ratchet Strap

- Lifting current

- Chain for Load Lifting

- Lifting equipment

- Slings

- Steel Cable Tensioner

- Polyester slingshot

- Load binders

- STEEL HOOK

- Steel Cable Clamp

- Electric winch

- Permanent magnets

- Steel Cable Clamp

- moitão

- Carabiners

- Screw With Eyelet

- Lifting Clamp

- Talha Manual

- Uncategorized

Call our consultants or chat online

+86 151 4514 5178

Complete Guide to Wire Rope Clips

What are Steel Cable Thimbles?

Steel wire rope thimbles are essential components used to create a reinforced loop (eye) in a steel wire rope. They help protect and extend the lifespan of the steel wire rope or sling by preventing wear caused by abrasion at the anchoring point. Thimbles are just one type of accessory for steel wire ropes, such as swaged terminals, wire rope clips, and other accessories.

Types of Steel Wire Rope Thimbles

Steel cable thimbles come in various strengths and materials, mainly carbon steel and stainless steel. They are generally divided into two types of use:

- For Light Use: These thimbles are galvanized and suitable for static applications.

- For Heavy Use: The heavy-duty thimbles are hot-dip galvanized, providing a thicker coating compared to the light-duty ones.

For high humidity or corrosive environments, stainless steel wire rope thimbles are recommended due to their resistance to rust, especially in maritime applications.

Installation of Steel Cable Thimbles

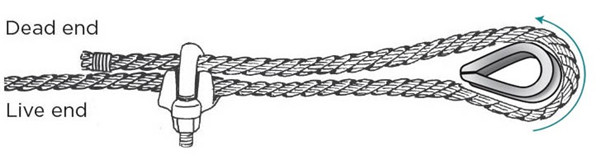

Step 1: Wrap the end of the steel cable around the outer groove of the thimble. Secure the loose end of the steel cable using clamps or swaged terminals. This fixes it at the anchor point, preventing wear from friction.

Step 2: Place another steel cable clamp near the loop above the thimble. Tighten the nuts firmly, but not completely to full torque. Use a crimping tool to secure the terminal to the cable, fastening the thimble loop.

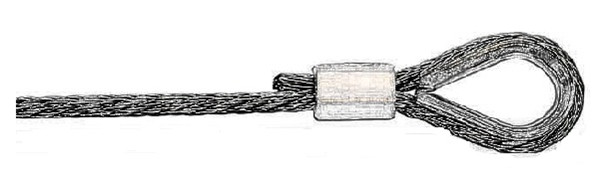

Alternatively, use a crimped terminal for faster installation. Refer to our materials for detailed instructions on using crimped terminals.

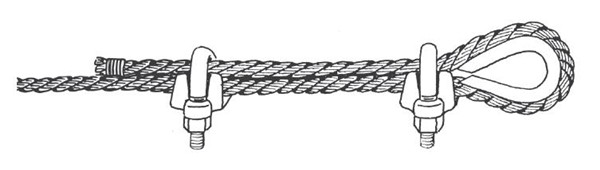

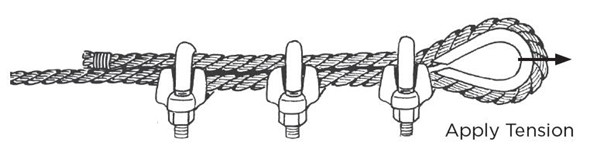

Step 3: Install additional wire rope clamps, spacing them evenly between the clamps already installed. Then, using an adjustable wrench, tighten all the clamps firmly according to the recommended torque. The clamps should be spaced at a distance equivalent to 6-7 times the diameter of the cable.

How to Use Steel Cable Thimbles

Steel wire rope thimbles are used with cables and ropes to protect the eyes, ensuring a smooth guide around curves. To ensure correct use:

- Choose the thimble of the appropriate size for the cable; for example, use a 1/2″ thimble for a 1/2″ uncoated steel cable.

- Make sure the thimble is securely fastened, without excessive looseness or overtightening, to ensure proper support for the other accessories.

- For vinyl-coated steel cables, use a larger thimble to compensate for the thickness of the coating. For example, for a 5/16″ vinyl-coated steel cable with a total diameter of 3/8″, use a 3/8″ thimble.

Explore our complete line of hardware for wire ropes and slings in our lifting accessories.

Share:

June Han /founder and designer

The co-founder of Hqlifting, sales director, amateur writer about fitness business