Need help? Write to us info@hqlifting.com

- Charging Accessories

- Lifting accessories

- Steel Cable

- Beam cart

- Turnstile for load securing

- Load Ratchet Strap

- Lifting current

- Chain for Load Lifting

- Lifting equipment

- Slings

- Steel Cable Tensioner

- Polyester slingshot

- Load binders

- STEEL HOOK

- Steel Cable Clamp

- Electric winch

- Permanent magnets

- Steel Cable Clamp

- moitão

- Carabiners

- Screw With Eyelet

- Lifting Clamp

- Talha Manual

- Uncategorized

Call our consultants or chat online

+86 151 4514 5178

How the electric winch works: Tips for efficient use

Understand how does an electric winch work It is the first step to make the most of its versatility. These pieces of equipment are essential in industries, workshops, and even at home. They facilitate the safe movement of heavy loads.

This article explains from the basic principle of operation to practical tips for keeping the equipment in good condition. You will discover how to choose, operate, and care for your electric winch safely and efficiently.

Whether for automotive repairs, construction, or leisure, the electric winch makes complex tasks more accessible. Discover how to optimize its use and avoid common problems without hassle!

What is an electric winch and its applications

An electric winch is a device that helps lift, transport, or secure heavy loads. It uses an electric motor to convert energy into mechanical force. This allows for precise and controlled operations. Saber how the electric winch is made inside helps you choose the best for your needs.

Main types of electric winches on the market

- Laptops: Light and ideal for use in vehicles or in non-fixed locations.

- Fixed: Permanently installed on structures, such as cranes or ramps.

- From column: With vertical design, common in workshops for vertical lifting.

- Automotive: Equip trucks for rescues or off-road mobility.

Differences between electric and hydraulic winches

| Feature | Electric | Hydraulic |

|---|---|---|

| Power source | Electric current | Oil pressure |

| Maintenance | Less complex | Requires constant lubrication |

| Noise | Less noisy | High noise level |

| Maximum load | Up to 5 tons | Higher capacities |

Common applications in industrial and domestic environments

In industries, these winches are essential for moving loads in logistics and assembly. At home, they help lift cars in garages or organize tools. The how the electric winch is made inside shows its efficiency where there is constant electric power.

Basic principles of operation of the electric winch

O how does an electric winch work It starts with the transformation of electrical energy into motion. When turned on, the electric current activates a motor. This motor generates rotation, which is then amplified by a gear system.

This increased force is what pulls heavy loads. The electric power, coming from an outlet or battery, is converted into mechanical movement. This movement operates the drum, causing it to wind or unwind the cable.

Electric winches use gears to increase force. The motor produces slow movement but with great power. This allows pulling stuck trucks or moving large loads in workshops.

O how does an electric winch work depends on three essential parts:

- Motor: Generates the initial rotation;

- Reduction system: Increases torque to pull loads;

- Cable and drum: They roll or unroll the load.

O how does an electric winch work also involves important concepts. For example, the rated capacity defines the maximum load that the winch can support. The duty cycle shows how long the equipment can operate without issues.

These factors are crucial to avoid damage to the winch. It is essential to understand that each part of the mechanism works together. From the control button to the cable that pulls the load.

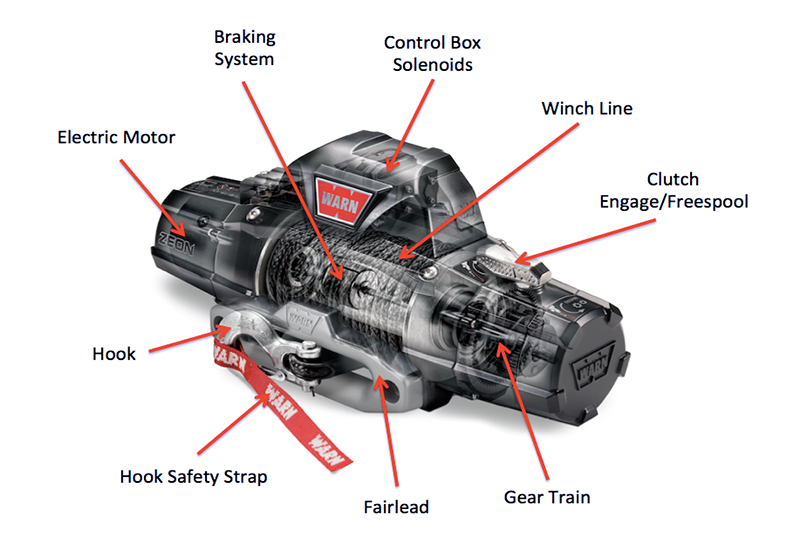

Essential components of an electric winch

To understand how an electric winch works, it is important to know its parts. Each part works together to provide strength, safety, and precision.

Electric motor: the heart of the equipment

The motor is essential for converting electrical energy into motion. It can be AC or DC, with power from 12V to 24V. It has thermal protection to prevent overload. The maximum force it can withstand is determined by the torque.

- AC Motors: Common in industrial applications

- DC Motors: Best for speed control

Gear and reduction system

The gear system increases the engine's power. There are types such as helical and planetary. They optimize the gear ratio.

| Gear | Operation | Application |

|---|---|---|

| Helicoidal | Reduces speed and increases torque | High-strength winches |

| Planetary | Compact and efficient in high-load applications | Portable and industrial models |

Drum and cable: how they work together

The drum holds the cable, which can support up to 5 tons. Materials such as stainless steel are used to prevent corrosion.

- 90-degree winding angle prevents wear

- Synthetic cables: More flexible, but with lower resistance

Control panel and functions

The panel controls the speed and direction. It offers options such as:

- Physical buttons for manual activation

- Radio frequency remote controls

- Temperature and maximum load indicators

Modern systems also have automatic lock sensors. They activate in case of overload.

How the electric winch works: internal mechanism explained

An electric winch has three essential parts: energy conversion, gears, and safety systems. These components work together. They ensure safety and efficiency when using the winch.

Conversion of electrical energy into mechanical force

The electric motor transforms power from the outlet into motion. When turning on the winch, the electric current makes the rotor spin. The gear system adjusts this force to pull heavy loads without overloading the motor.

How the gear of an electric winch is made

The gears are made of special steels to last longer. There are types such as helical and planetary. They reduce speed and distribute force evenly:

- Helical gears: reduce noise and transmit motion in parallel shafts;

- Bevel gears: align torque at different angles;

- Planetary systems: They amplify force using rotating gears around a central axis.

The choice of design varies according to use. For heavy loads, stronger materials are used. For home use, silence is prioritized.

Brake and safety system

The brake system prevents the load from falling in case of failure. Electromagnetic brakes automatically lock when the motor stops. In electrical failures, systems like mechanical springs hold the load until the problem is resolved. This prevents accidents in critical situations.

Column electric winch: specific features

O column electric winch for 300kg 220v It is very stable and precise. It has a vertical structure and uses a fixed column. This ensures that everything stays properly aligned.

The motor operates on 220V, which is common in many houses and workshops. This makes installation very easy.

- Swivel arm for angular adjustment up to 180°;

- Floor or wall mounting system to prevent displacement;

- Speed of up to 5m/min and maximum height of 3 meters.

| Feature | Detail |

|---|---|

| Maximum load | 300 kg |

| Voltage | 220V |

| Maximum height | 3 meters |

| Average consumption | 2.5 kW/hour |

This winch is great for small industries or workshops. It is very precise in vertical movement. The column structure helps maintain balance.

It is important not to load more than 300 kg. Also, do not use in damp places without electrical protection.

Check if the mains voltage is 220V before purchasing. Also, consider the space for the column. Keeping the motor and cables in good condition is essential for safety and durability. The column electric winch is a good choice for those who need power and space.

How to properly operate an electric winch

Before starting, it is essential to check the equipment and the location where it will be used. Safety begins with preparation. Check the following items:

Preparation for use

- Visual inspection of cables, drums, and connectors;

- Confirmation of the voltage compatible with the manual;

- Removal of obstacles within the winch's range;

- Mandatory personal protective equipment (PPE).

Step-by-step operating procedures

- Turn on the winch and check the indicator lights;

- Adjust the steering (pull or release) with the selector;

- Gradually press the trigger button;

- Monitor audible or visual warning signals;

- Turn off after use and release the tension of the cables.

How does an electric column winch panel work

The central panel controls all the winch functions. The main elements are:

- Emergency button (red): to stop immediately;

- Speed control: gradual motion adjustments;

- Status lights: green (normal operation), red (problem);

- Display digital: indicates load in use and maximum limits.

Attention to symbols: a triangle with an exclamation mark indicates necessary checks. Always consult the manufacturer's manual for specific adjustments.

Tips to maximize efficiency and lifespan

To make your electric winch last longer, follow some important tips. They help maintain safety and performance. Knowing how an electric winch works helps prevent damage and maintain efficiency.

Best operating practices

- Turn off the engine every 15 minutes to cool the components.

- Avoid accelerating or stopping abruptly. Make smooth movements to avoid overloading the system.

- Place the winch aligned with the load. This prevents the drum from being overloaded.

- Check if the cable winds evenly on the drum. This helps prevent damage.

Load management and weight limits

Respect the maximum capacity of your winch. Follow these rules:

| Factor | Influence on load limit |

|---|---|

| Lifting angle | Less than 45° reduces 30% from the nominal capacity |

| Number of pulleys | Each added pulley decreases efficiency by 10% |

- Never exceed 80% of the maximum capacity for safety.

- Use weight measuring devices to avoid accidental overload.

- In diagonal movements, multiply the load weight by 1.5 to calculate the effective load.

If you hear abnormal sounds or feel vibrations, it is a sign of overload. Stop and check the setup before continuing.

Preventive maintenance of the electric winch

To keep the electric winch working well and safe, it is crucial to perform preventive maintenance. Knowing how it works helps identify important parts to check frequently. This way, problems are avoided before they happen:

- Daily: Check wires, electrical connectors, and signs of wear on cables and hooks.

- Weekly: Clean dust from motors and gears. Lubricate points recommended by the manufacturer, such as shafts and bearings.

- Monthly: Check the drum alignment and the integrity of the internal gears.

- Annually: Hire a technician to inspect complex components, such as brake systems and electrical circuits.

If you hear noises or feel vibrations, this may be a sign that something is wrong. Use lubricants made for electric machines. Avoid greases that could damage the equipment. Keep a record of inspections to know when to replace parts. This helps keep the winch in good condition. Understanding how it works helps prevent costly problems and accidents.

Common troubleshooting

Problems with the 300kg 220v column electric winch can be resolved with care. It is important to know the common causes to avoid unexpected stops. See the tips below to safely identify and fix issues.

Frequent electrical problems

- Motor does not start: Check if the 220V connection is secure. Poor contacts or burned circuit breakers can block the how does a 300kg 220v column electric winch work. Replace damaged fuses and test the voltage.

- Abnormal noises or overheating: Clean the engine ventilation and check internal lubrication. Persistent noises may indicate component wear.

Mechanical failures and solutions

Mechanical problems require immediate attention:

- Cable coils irregularly: Adjust the cable tension and remove blockages with a dry cloth.

- Drum locked: Turn off the equipment and release the mechanism with a screwdriver. Avoid sudden force.

When to call a technician

Some cases require professional help:

- Brake system or engine failures after repair attempts.

- Peeling paint or deformations in the structure of the winch.

- Complex electrical errors, such as short circuits or control board failure.

Before calling a specialist, document unusual sounds, display errors, and recent usage conditions. This helps with quick diagnosis.

Safety rules for the use of electric winches

It is very important to follow safety standards to avoid accidents. Using personal protective equipment (PPE) is mandatory. See the essential items:

- Helmet: Protects against falling objects.

- Non-slip gloves: They assist in cable handling and reduce the risk of shocks.

- Safety glasses: Avoid dust projections or loose parts.

- Footwear with toe protection: They protect the feet from impacts.

Before use, check that the structure is stable. Never stand under a suspended load. The cable must be free of bends, as deformations affect the gear.

Excessive pressures can cause failures. Follow NR-12 and NR-11 standards, which require inspections and operator training.

In emergencies, turn off the device and follow the company's plan. Update knowledge through technical courses. Safety requires attention to all details.

Conclusion

Understanding how an electric column hoist panel works is crucial. We saw that the electric motor, gears, and control panel work together. This allows moving loads with precision.

Knowing how to operate the winch panel helps prevent overloads. This improves productivity in various areas. Industries, agriculture, and even homes that use heavy-duty equipment benefit.

Preventive maintenance and safety standards are essential. They ensure that the electric winch works well for years. Knowing the control panel helps to safely adjust speeds and directions.

Companies like Trotec and Fermax offer advanced models. They combine technology and durability, meeting the demands of the United States market.

Investing in training for operators and regular technical inspections is important. This keeps the equipment in good condition. With advancements like smart sensors, the electric winch becomes even safer.

Mastering the electric column hoist panel brings technical advantages. But it is also a tool to improve processes in any work environment.

FAQ

How does an electric winch work?

An electric winch uses electrical energy to create mechanical force. This happens through a motor and a gear system. Thus, it can lift, lower, or drag loads efficiently and safely.

How is the gear of an electric winch made?

The winch gear is made of treated steel. This ensures its durability. The design varies, being helical, planetary, or bevel, to improve strength and efficiency.

How is the electric winch made inside?

Inside, an electric winch has a motor that converts electric current into motion. This motion is amplified by gears, allowing the lifting of heavy loads.

How does a 300kg 220v column electric winch work?

A 300kg electric winch for 220v uses an electric motor. It is designed to support heavy loads. It offers stability and safety in industrial or mechanical environments.

How does an electric column winch panel work?

The electric column hoist panel has buttons and indicators. They allow the operator to control the lifting. It includes safety features, such as emergency stops, for safe operations.

What are the most common applications of the electric winch?

Electric winches are used in mechanical workshops, construction, and homes. They are perfect for lifting and transporting heavy materials. They facilitate maneuvers and improve efficiency in load handling tasks.

Share:

June Han /founder and designer

The co-founder of Hqlifting, sales director, amateur writer about fitness business