Need help? Write to us info@hqlifting.com

- Charging Accessories

- Lifting accessories

- Steel Cable

- Beam cart

- Turnstile for load securing

- Load Ratchet Strap

- Lifting current

- Chain for Load Lifting

- Lifting equipment

- Slings

- Steel Cable Tensioner

- Polyester slingshot

- Load binders

- STEEL HOOK

- Steel Cable Clamp

- Electric winch

- Permanent magnets

- Steel Cable Clamp

- moitão

- Carabiners

- Screw With Eyelet

- Lifting Clamp

- Talha Manual

- Uncategorized

Call our consultants or chat online

+86 151 4514 5178

Shackle Sling Guide: Shackle Sizes and Materials

Shackles come in various types, sizes, and qualities to meet the needs of different rigging tasks. Therefore, to select the correct shackle, it is essential to understand its fundamental attributes.

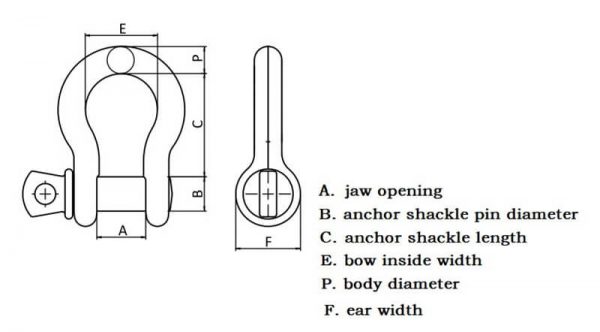

Shackle Dimensions

When dealing with small or large shackles, it is important to note that the diameter of the shackle pin is usually larger than the diameter of the shackle body. However, the standard size of shackles is determined by the diameter of the body, not the pin. The figure below illustrates how to measure the length of the shackle:

Due to the variety of shackle sizes, their weights also vary. Generally, the variation in size or weight should not exceed ±5% of the standard sizes (for example, RR-C-271 and ASME B30.26 shackles). The most common shackle sizes on the market are 3/4 inch, 5/8 inch, 1/2 inch, 1 inch, 3/8 inch, and 7/8 inch.

Materials of the Tiles

The design of lifting shackles considers load capacity, performance, and environmental conditions. These factors are mainly influenced by the materials used. Shackles are typically categorized into three types based on the material: carbon steel shackles (low carbon steel), alloy steel shackles, and stainless steel shackles (stainless steel). For more information about the materials used in rigging equipment, see this informative article.

Carbon Steel Shackles

Our standard shackles have a safety factor of 6:1 or 4:1 and are available with hot-dip galvanized or electro-galvanized finish. They are available with round pin, threaded pin, and pin with nut and cotter pin.

Alloy Steel Shackles

Alloy steel shackles have superior mechanical properties, making them suitable for supporting higher loads and resisting fatigue, even under extreme conditions. Our grade 80 alloy steel shackles have a safety factor of 5:1 and offer a nominal working load (WLL) similar to carbon steel shackles, with a more compact and lightweight design.

Stainless Steel Shackles

Stainless steel shackles have excellent corrosion resistance due to the thin layer of chromium oxide that forms on their surface. They are ideal for marine applications, performing well in saltwater or chemical environments. Although generally more expensive than galvanized shackles, stainless steel shackles offer superior protection against rust and corrosion due to the presence of molybdenum, an alloying element found in stainless steel, making them suitable for extreme conditions or environments with high chloride content.

Both stainless steel shackles and galvanized ones offer some protection against rust and corrosion, but stainless steel is the superior option.

Galvanized shackles have only a thin layer of zinc, while stainless steel has natural resistance to rust and corrosion.

Understanding the dimensions and materials of shackles is essential to determine their classification and price in the context of rigging. By becoming familiar with these aspects, it becomes easier to select the appropriate shackle. However, it is always recommended to consult manufacturers for accurate information.

Share:

June Han /founder and designer

The co-founder of Hqlifting, sales director, amateur writer about fitness business