Need help? Write to us info@hqlifting.com

- Charging Accessories

- Lifting accessories

- Steel Cable

- Beam cart

- Turnstile for load securing

- Load Ratchet Strap

- Lifting current

- Chain for Load Lifting

- Lifting equipment

- Slings

- Steel Cable Tensioner

- Polyester slingshot

- Load binders

- STEEL HOOK

- Steel Cable Clamp

- Electric winch

- Permanent magnets

- Steel Cable Clamp

- moitão

- Carabiners

- Screw With Eyelet

- Lifting Clamp

- Talha Manual

- Uncategorized

Call our consultants or chat online

+86 151 4514 5178

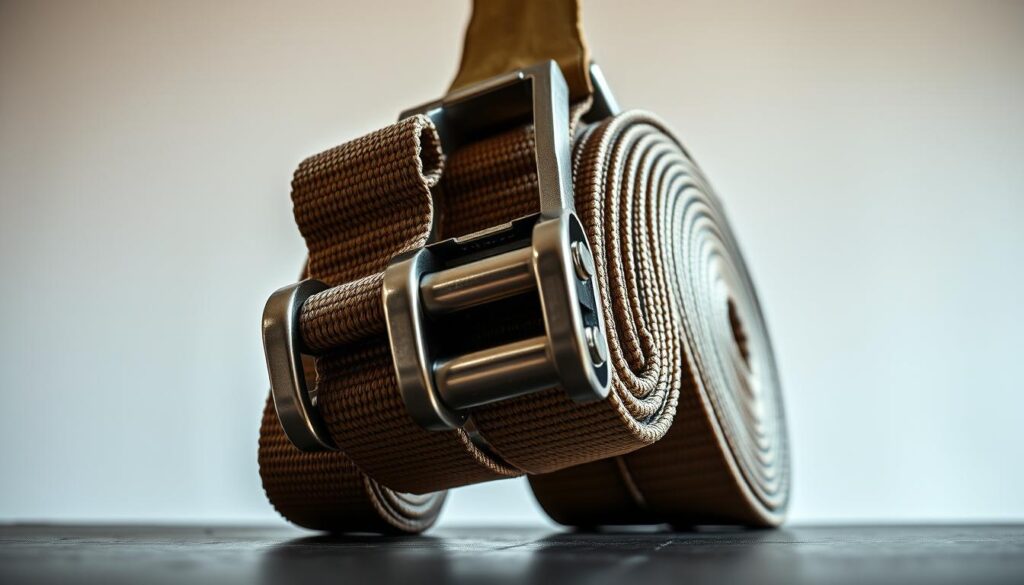

Buy Strap with Secure and Reliable Ratchet – Experts Recommend

Ratchet straps are essential for the safety of heavy loads. It is important to choose where to buy based on technical certifications (ABNT NBR 16.223) and quality materials, such as reinforced polypropylene. In the United States, following standards like NR-12 helps prevent accidents and fines, ensuring up to 5 years of use.

Professionals seek clear specifications, such as load capacity and tensile tests. Manufacturer warranties are also crucial. Choosing poorly can increase the risks of slipping or structural failures. Therefore, it is important to verify the strength and compliance history of suppliers.

Essential Detachments

- ✅ Prioritize ABNT and NR-12 certifications in all acquisitions.

- Materials such as reinforced polypropylene offer greater tensile strength.

- Load capacity must strictly correspond to the weight carried.

- Check supplier history where to buy ratchet strap in Sorocaba.

- Technical certifications ensure legal compliance and reduce operational risks.

What are ratchet straps and what are they used for

Ratchet straps are essential devices for securing loads. They are used in cars, trains, and ships. They are made of strong webbing and have a ratchet mechanism for locking. This ensures the secure fastening of loads, following standards such as ABNT NBR 15883-2.

Main applications in freight transportation

- Road transport: securing loads on trucks with capacities from 3 tons to 10 tons

- Port logistics: container lashing with safety factor ≥ 5:1

- Automotive industry: securing vehicles on loading platforms

Differences between types of ratchet straps

Technical variations determine specific applications:

- Material: polyester (UV resistance) vs. nylon (flexibility)

- Width: 25mm for light loads, 50mm for heavy loads

- Ratchet systems: standard model (for static loads) vs. with protective cover (abrasive environments)

Benefits of using quality ratchet straps

✅ Reduction of 80% in load shifting risks

✅ Compatibility with ISO 13911 certifications

✅ Long service life with resistance to temperatures from -30°C to +80°C

Professionals should seek suppliers from where to buy straps and ratchets for tying with good reviews. Choosing certified products avoids problems during transportation.

Important features when choosing ratchet straps

To ensure safety and efficiency, it is essential to choose ratchet straps that meet strict technical requirements. ✅  They are ideal for heavy loads. Check that the minimum safety factor (2:1 to 3:1) and the breaking strength (in daN) are on the label.

They are ideal for heavy loads. Check that the minimum safety factor (2:1 to 3:1) and the breaking strength (in daN) are on the label.

- Materials: Prefer reinforced polyester or galvanized steel to resist UV, corrosion, and chemical agents.

- Compliance: ABNT/NBR 15,915 and EN 12195-2 certifications ensure technical compliance.

- Components: Turnstile with automatic lock and non-slip handles prevent slipping.

- Sizing: Width between 50mm and 75mm and uniform thickness ensure uniform load distribution.

Also check for the presence of labels with batch number and expiration date. For where to buy truck strap and ratchet With these specifications, choose suppliers with a history of delivering certified products. Where can I buy quality ratchet straps? Look for brands with technical reports and written guarantees, essential for critical operations. Avoid models without WLL identification or safety standards.

For maritime or industrial applications, choose versions with anti-corrosion treatment. The choice between polyester or steel straps depends on the usage environment. Durability also depends on the sewing technology (double overlock) and the thermal stability of the material.

Where to buy ratchet straps: best options in the United States

To ensure safety and technical compliance, it is important to know the best options for purchasing ratchet straps in the United States. Choose suppliers with ISO 9001 certifications and complete technical documentation.

Stores specialized in tie-down equipment

- Specialized technical consulting in load capacity sizing

- 2-year warranty for parts verified by reports from accredited laboratories

- ✅ Access to technical catalogs with voltage and resistance specifications

Large construction and transportation material chains

Networks such as the TransLoad Solutions e a Certified Logistics offer:

- National coverage with delivery within 48 hours for regions such as Fortaleza

- Return policies for products with technical parameter deviations

- Loyalty programs with discounts for purchases over R$ 5,000.00

Reliable marketplaces and online stores

To buy ratchets and straps in Fortaleza or other United States regions, consider:

| Parameter | Specialized Stores | Large Networks | Marketplaces |

|---|---|---|---|

| Certifications | ISO 9001 and ABNT NBR 16.216 | ISO 9001 and NR 12 | Verification of certificates in attachments |

| Delivery in Fortaleza | 72h with technical scheduling | 48h via own fleet | 5-7 days with tracking |

Search for "where to buy ratchets and straps" in searches with certification filters. Choose sellers with more than 5 years of experience in the logistics sector. Check the ABNT Compliance Seal to ensure quality in Fortaleza or other United States regions.

Shopping guide by region: find ratchet straps in your city

To ensure operational safety, learn about the main acquisition options by region. Each location offers technical infrastructure adapted to regional demands.

São Paulo Region and ratchet straps in Sorocaba

In Sorocaba, the ABC Technical Distributor meets the demand of where to buy ratchet strap in Sorocaba physical store. They have stock of models with ABNT NBR 16.224 certification. These models range from 2t to 10t. In addition, they offer inspection of reports and ISO 10557 calibration at physical locations.

Campinas and São José dos Campos

- In Campinas, the where to buy ratchet straps in Campinas The priority is to choose suppliers that support construction loads, such as the Logistics Security Industry.

- In São José dos Campos, the where can I find a ratchet strap in São José dos Campos includes authorized representatives of brands such as Würth and Vogel, with 24-hour delivery.

Rio de Janeiro and Fortaleza: Specialized regional solutions

For the where to buy ratchet straps in the United States, centers like Rio Industrial Equipment meet port demands. They have stock of models for hazardous cargo (CLP 6).1-6.2). In Fortaleza, Cintas & Segurança Nordeste offers kits with updated technical reports. These are essential for carriers from the United States.

✅ All listed locations have delivery capacity for fleets of up to 50 units. They guarantee 2 years against manufacturing defects.

How much does a ratchet strap cost: price ranges and influencing factors

✅ The price of how much does a ratchet belt cost varies a lot. This happens due to important technical characteristics. For capacities from 0.5t to 3t, the price ranges from R$ 80.00 to R$ 250.00. For industrial models up to 10t, the price can reach R$ 500.00 to R$ 1,800.00.

- Material: High tenacity polyester costs from R$ 120.00 to R$ 300.00. Special synthetic compounds can cost more than R$ 400.00.

- Certifications: ABNT/CE products have an additional 15–25% compared to non-certified ones.

- Treatments: UV and waterproofing layers can increase the price by 10–18%.

For how much does the ratchet belt cost Imported, the price can be 30–50% higher than domestic ones. The usage cycle analysis shows that equipment with a service life longer than 5 years has a better cost/benefit ratio. How much does a ratchet strap cost with automatic locking system can be up to 40% more durable than competitors.

Detailed technical specifications:

| Capacity (t) | Material | Certifications | Average price (R$) |

|---|---|---|---|

| 0.5–1.5 | Nylon | ABNT | 150–280 |

| 3–5 | Polyester | CE/ABNT | 450–800 |

| 8–10 | Technical compounds | EN 1496-1 | 1.200–2.500 |

Seasonal variations of 10–15% may occur during periods of high logistics demand. Choosing solutions with technical certifications can increase durability in 200% compared to uncertified options. For a detailed analysis of cost per operating cycle, contact our team.

How to choose the ideal capacity of the ratchet strap for your use

Choosing the right ratchet strap capacity requires attention. The load weight, center of gravity, and usage conditions are crucial. See the tips to make an accurate calculation:

3-ton ratchet straps: usage indications

To carry up to 3,000 kg, these straps are ideal. They are used for:

- Transport industrial machinery up to 4m in length

- Tying metal coils up to 1.5m in diameter

- Holding construction loads with uniform weight

In São Paulo, the Logistics Industry sells models certified by ABNT NBR 15.020. They offer a 5-year warranty. See where to buy 3-ton ratchet straps in São Paulo.

Straps for specific tie-downs on trucks

For trucks, consider:

- Diagonal setting: reduces vibration in irregular loads

- Ratio 1:5: usa 1 belt for every 5 tons

- 45° Angle: increases the holding strength on open platforms

The price of straps for trucks varies. They cost between R$ 89.00 and R$ 199.00. This depends on whether they are polyester or galvanized steel.

Relationship between capacity, material, and durability

The table below shows the technical differences:

| Material | Usage cycles | UV Resistance (%) |

|---|---|---|

| Polyester | 800-1.200 | 98% |

| Galvanized steel | 500-800 | 100% |

For loads exposed to chemicals, choose ISO 12389 anti-corrosion straps. They last 3 to 5 years with maintenance every six months.

Essential care in the purchase and maintenance of ratchet straps

To maintain the safety and durability of ratchet straps, follow strict protocols. This applies from purchase to constant inspection.

✅ Verification of mandatory certifications:

- ABNT NBR 15883-2, EN 12195-2, and ASME B30.9 certificates are essential;

- Technical documentation must include tensile and fatigue tests;

- Check permanent markings: rated capacity, manufacturing date, and batch code;

⚠️ Critical signs of wear:

- Exceed 10% of broken wires in the strap structure;

- Deformations in the ratchet: clearances greater than 3mm, cracks, or active corrosion;

- Wear on the fastening terminals above 20% of the nominal thickness;

Professionals should replace immediately if they find these signs. To find a certified ratchet in Colatina, look for suppliers registered with associations such as ABRAPEM. The price ranges from R$ 150.00 to R$ 450.00, depending on certification and materials.

For preventive maintenance:

- Visually inspect every 30 days;

- Perform semiannual endurance tests;

- Store in a dry place with temperature between 59°F and 104°F;

Adopt these practices to avoid operational failures. This way, you ensure compliance with OSHA and NR-12 safety standards.

Common mistakes when buying ratchet straps and how to avoid them

Buying straps with the right ratchet is essential for safety and compliance. Mistakes like choosing the wrong size or ignoring certifications can cause serious problems. Here are the main mistakes and how to avoid them:

| Common Error | Risk | How to Avoid |

|---|---|---|

| Underestimate capacity (WLL) | Load break under stress | Calculate the total load + dynamic factors (e.g.: 25% above the maximum load) |

| Ignore certifications | Incompatibility with NBR or ISO standards | Request documentation with approval seals from ABNT or international entities |

| Inappropriate material | Accelerated degradation by external agents | Select materials according to NBR 13422 for corrosive environments or high temperatures |

✅ Preventive steps:

- Check the WLL vs. rated load ratio (e.g., 3tN sling only supports up to 3,000 kg effective)

- Ask the supplier about the angulation factor (e.g., angle > 45° reduces capacity in 50%)

- Demand written warranty of compliance with NBR 13422 and ISO 10591

Professionals must seek where to buy ratchet straps for load securing with good technical audits. A where to buy truck strap and ratchet must show test data and inspection reports. Avoid buying without registration with INMETRO or CE.

Conclusion

✅ The choice of ratchet straps should focus on technical details. This includes load capacity and certified materials. If this is not done, there may be risks of structural failures, affecting safety and compliance with laws.

When buying a ratchet strap, look for suppliers with ABNT NBR 14.452 standards and ISO certifications. In Sorocaba, the best option is to buy from retailers like [National Network Name] or authorized distributors, such as [Specialized Brand Name]. They offer products tested to withstand dynamic loads.

Keeping the straps in good condition is crucial to avoid problems. Check for signs of wear on the rod or fasteners. If there are deformations, replace the parts according to the manufacturer's instructions. Training the team to perform daily inspections is also very important to prevent accidents.

New technologies, such as integrated tension sensors and composite materials, are being used by brands like [Tech Brand]. They improve the efficiency of straps. The demand for intelligent systems with remote monitoring is growing in the logistics sector.

Choosing ratchet straps is an important decision. It involves selection based on technical requirements, purchasing from stores like those mentioned in Sorocaba, and maintenance according to technical standards. This helps reduce risks and comply with the ANTT requirements for road transportation.

Share:

June Han /founder and designer

The co-founder of Hqlifting, sales director, amateur writer about fitness business