Lever Winch with Steel Cable WRH-HS

Item number: 1903

The WRH-HS model lever lever hoist with steel cable features a durable steel construction, designed for versatility and portability. This hoist is ideal for pulling, lifting, lowering, and securing loads, ensuring ease of use and safety.

Available capacities:

- 0.8t x 20m

- 1.6t x 20m

- 3.2t x 20m

Main Features:

- Steel Structure: Robust and reliable for demanding applications.

- Versatile Operation: Suitable for lifting, towing, and securing, even over long distances.

- Efficient and Secure: O guincho opera com um cabo de aço que passa através das mandíbulas. As mandíbulas duplas abrem sequencialmente, garantindo que o cabo de aço permaneça firmemente fixo durante o uso.

- Testado Sob Carga: Cada guincho é testado com 1,5 vezes o Limite de Carga de Trabalho (WLL, do inglês *Working Load Limit*) antes do envio.

- Design Compacto: Construção leve para fácil manuseio e transporte.

- Revestimento de Alta Durabilidade: Possui revestimento em pó e componentes estruturais galvanizados, garantindo alta durabilidade.

- Recursos de Segurança: Equipado com pinos de segurança substituíveis para evitar sobrecarga (acompanha três pinos sobressalentes).

- Cabo de Aço Incluído: Fornecido com um cabo de aço de 20 metros com um gancho de travamento; comprimentos adicionais disponíveis sob consulta.

- Documentação Completa: Cada guincho acompanha certificado de teste e manual do usuário.

- Peças de Reposição Disponíveis: Para manutenção e suporte contínuos.

- Opção de Gancho Giratório: Um gancho giratório pode ser acoplado ao corpo para maior flexibilidade.

- Materials: Fabricado com aço de alta qualidade.

- Marcação: O produto é marcado com marca, modelo, WLL, tamanho do cabo de aço, número de série, instruções de operação, data e marcação CE.

- Padrões: Em conformidade com a norma EN 13157.

- Safety Factor: 4:1.

Especificações Técnicas:

- Item number

- Capacidade Nominal

- Distância de Movimento do Cabo por Curso

- Força de Tração da Alavanca em WLL

- Diâmetro do Cabo

- Comprimento Padrão do Cabo de Aço

- Peso Líquido sem Cabo de Aço

- Peso do Cabo de Aço

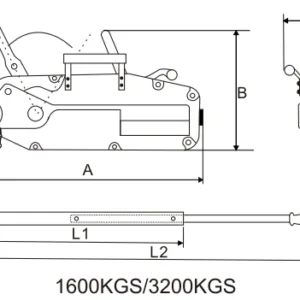

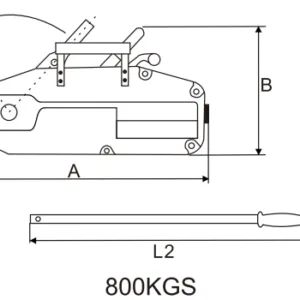

- Dimensões Máximas (mm)

- L1 (cm)

- L2 (cm)

- Product Code

Cada guincho é rigorosamente testado para garantir a conformidade com os padrões de alto desempenho e segurança. Estamos comprometidos em fornecer soluções confiáveis de elevação e tração.

Guincho Tirfor (Guincho de Tração com Cabo de Aço) – Especificações

WRH-HS008

- Capacity: 800 kg

- Minimum Cable Length: ≥52 meters

- Lifting Speed: 353 mm/min

- Peso: 8.3 kg

- Dimensions: 20x7x6.3 cm

- Cable Length: 435 meters

- Lifting Height: 245 meters

- Product Code: 190300800

WRH-HS016

- Capacity: 1600 kg

- Minimum Cable Length: ≥55 metros

- Lifting Speed: 412 mm/min

- Peso: 11 kg

- Dimensions: 20x12x12 cm

- Cable Length: 545 meters

- Lifting Height: 286 meters

- Product Code: 190301600

WRH-HS032

- Capacity: 3200 kg

- Minimum Cable Length: ≥28 meters

- Lifting Speed: 441 mm/min

- Peso: 16 kg

- Dimensions: 20x23x22.5 cm

- Cable Length: 655 meters

- Lifting Height: 345 meters

- Product Code: 190303200

Related Products

- Chain Paddle Type CH-B

- LH-A Type Lever Handle

- Trole Manual Type PT-FA

- Permanent Lifting Magnet Type PML

Safe Use of the Tirfor Winch (Cable Puller Winch)

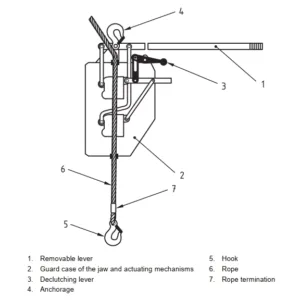

A claw winch is a device used to lift, lower, and secure loads using a cable. The cable is moved or held by claws, which are manually operated through a lever mechanism.

An operation cycle consists of lifting and lowering movements, over a minimum vertical distance defined by the length of the cable.

The mechanical strength of the claw winch must be verified through appropriate calculations. The winch utilization factor must be at least 4:1.

The lifting lever must be equipped with a mechanism that limits the force exerted.

The lifting lever must be equipped with a mechanism that limits the applied force. This mechanism must limit the lifting force to a value not exceeding twice the rated capacity.

The claw winch must withstand 400 cycles at its nominal capacity without failure or replacement of parts, in addition to the necessary lubrication of the cable.

Always:

- It is recommended to store and handle the wire rope traction winch correctly.

- Inspect the winch, the cable, and the accessories before use and storage.

- Make sure that the installation and suspension points are secure and capable of supporting the entire load.

- Make sure the machine is properly aligned with the cable and that the cable is free of obstructions.

- Use only the correct cable provided with the winch.

Never:

- Never use a twisted or damaged cable or a cable with broken wires.

- Do not force or extend the operating lever.

- Do not operate the lifting and lowering levers simultaneously.

- Do not use the winch with a steel cable if the cable is twisted or stuck.

- Do not use the winch to lift people unless it is specifically designed for that purpose.

Choosing the Right Tirfor Winch (Cable Puller with Steel Cable)

Steel cable traction winches are available in a variety of capacities with manual operation (as well as hydraulic operation for specific applications) for lifting and traction features. Various cable lengths are available. When selecting a winch, consider the following:

- Machine Type: Manual or hydraulic, lifting or pulling capacity.

- Cable Length: Make sure the length is suitable for your needs, including options for cable collection or winding.

- Lifting Equipment Arrangement: Consider guide pulleys, pulley assemblies, anchor points, and suspension points.

- Applied Load: Make sure the winch can handle the required load.

Consult the supplier if the winch is used for lifting people.

Storage and Handling of the Tirfor Winch (Cable Puller Winch)

Never store winches, cables, or damaged accessories. Make sure they are clean, dry, and protected against corrosion. When storing the cable, carefully wind it onto a reel or frame, making sure there are no twists.

Store the machine and the cable on appropriate shelves, instead of on the floor, to avoid damage.

Installation and Commissioning

Follow the supplier's specific installation and commissioning instructions, as well as the general requirements described above.

Safe Use of the Tirfor Winch (Cable Puller Winch)

Always:

- Handle all steel cable winches with care and follow safety guidelines.

Safety Instructions for Using a Winch with Steel Cable

- Use Only Equipment in Good Condition

Make sure the winch, cables, pulleys, and other related components are in good condition and free of defects. Never use defective equipment. - Check the Rigging Assembly

Check that all anchor and suspension points are strong enough to support the applied load. - Install the Cable Correctly

Make sure to use the correct type of cable, checking that it is not twisted or knotted. Ensure that the winch is properly aligned with the cable. - Respect the Safe Work Load Limits (SWL)

Never exceed the marked nominal load (SWL). Make sure that the traction does not exceed the specified limits for the traction application. - Handle the Lever Safely

Always use the operating lever provided with the winch. Do not use pipes or other modifications to extend the lever, as this may damage the equipment or cause the safety pins to break. - Do Not Operate the Lift and Lower Levers Simultaneously

Do not operate the winch lift and lower levers simultaneously to ensure safe and efficient operation. - Passenger Transport

For passenger transportation applications, use only equipment designed or

Reviews

There are no reviews yet.