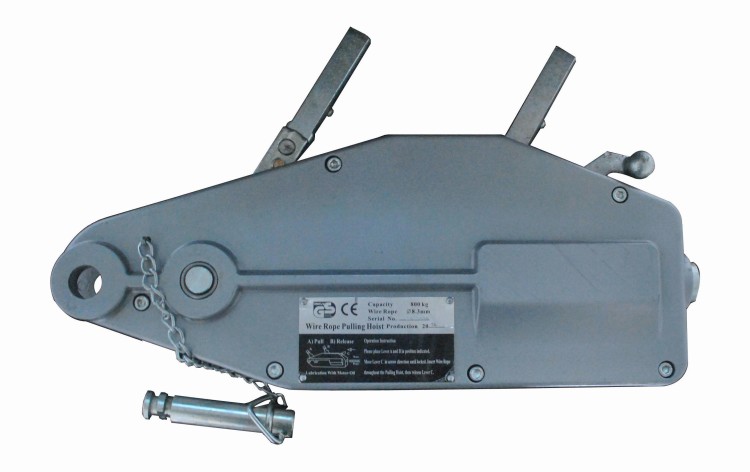

Steel Cable Winch (Tirfor) Model WRH-S

Product code: 1902

The WRH-S Steel Cable Winch is a robust and versatile winch with a durable steel construction. It is designed for various tasks, such as pulling, lifting, lowering, and securing loads.

This winch was designed to be easy to use, safe, and portable.

Optional Models:

- 800kg x 20m

- 1600kg x 20m

- 3200kg x 20m

Product Overview

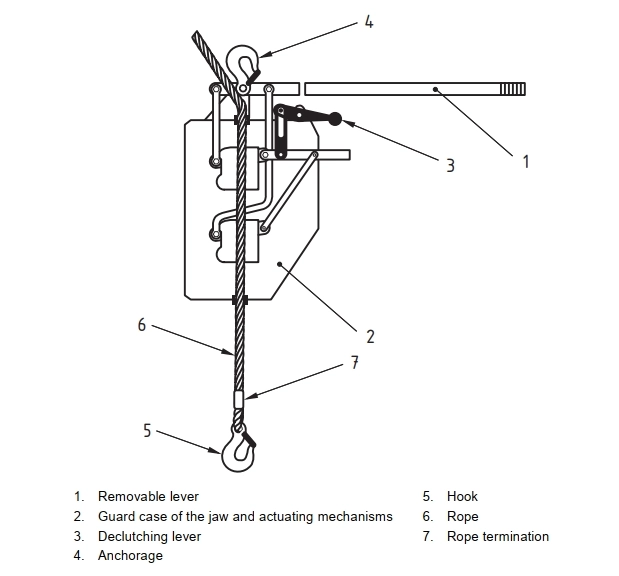

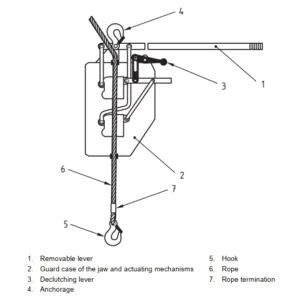

The H-Lift WRH-S Steel Wire Rope Winch is a compact and lightweight unit, ideal for long-distance lifting, pulling, and tensioning. The winch is operated by a steel wire rope that passes through a set of grips. A double set of grips operates alternately, pulling the steel wire rope and keeping it tensioned.

Main Features:

- Each winch is dynamically tested with 1.5 times the Rated Capacity before shipping.

- Compact and lightweight design for easy operation.

- Robust construction with powder-coated and galvanized frame components.

- Equipped with replaceable shear safety pins to prevent overload (3 spare pins included).

- Includes 20 meters of steel cable wound with a locking hook. Custom lengths available upon request.

- Spare parts available.

- Material: High-quality steel.

- In compliance with the EN 13157 standard.

- Safety factor: 4:1.

Technical Specifications

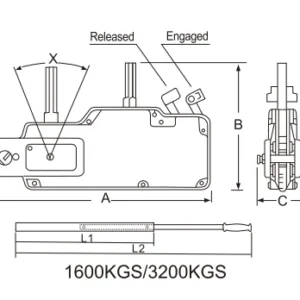

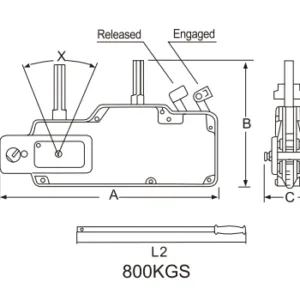

| Product code | Nominal Capacity (kg) | Cable Movement per Stroke (mm) | Nominal Manual Force (N) | Cable Diameter (mm) | Standard Length of Steel Cable (m) | Net Weight without Steel Cable (kg) | Weight of Steel Cable (kg) | Dimensões Máximas (mm) | L1 (cm) | L2 (cm) |

|---|---|---|---|---|---|---|---|---|---|---|

| WRH-S008 | 800 | ≥52 | 343 | 8.3 | 20 | 8 | 6.3 | 440 | 26,5 | 6,3 |

| WRH-S016 | 1600 | ≥55 | 441 | 11 | 20 | 14.5 | 12 | 550 | 30,0 | 7,7 |

| WRH-S032 | 3200 | ≥28 | 441 | 16 | 20 | 28 | 22.5 | 690 | 35,0 | 9,1 |

L1: Total length (cm); L2: Width (cm)

Related Products

- Chain Paddle Model CH-B

- Lever Handle Model LH-A

- Manual Movement Cart Model PT-FA

- Permanent Lifting Magnet Model PML

# Uso Seguro do Guincho de Tração com Cabo de Aço

O guincho de alavanca com cabo de aço (guincho de garra) é um equipamento que utiliza um cabo para elevar, abaixar e manter cargas. O cabo é preso ou movido por garras, e a força humana é aplicada através de uma alavanca ou múltiplas alavancas.

O ciclo de operação compreende o movimento de elevação e descida de todos os componentes relevantes do guincho de garra, em uma distância vertical mínima determinada pelo comprimento do cabo.

A resistência mecânica do guincho de garra deve ser verificada por meio de métodos de cálculo apropriados. O fator de segurança do guincho de garra deve ser de pelo menos 4:1.

A alavanca de elevação deve ser equipada com um mecanismo para limitar a força aplicada. Este mecanismo deve limitar a força de elevação a não mais que o dobro da carga nominal.

O guincho de garra deve support 400 cycles under nominal load. During this process, no failures, part replacements, or stops should occur, except for the necessary lubrication of the cable.

Recommendations:

- Store and handle the wire rope traction winch properly.

- Inspect the machine, the cable, and the accessories before use and before storing.

Make sure to install the correct and appropriate cable, and that the cable is free of twists or tangles. The machine must be properly fitted to the cable for optimal performance.

- During lifting operations, do not exceed the Safe Working Load (SWL) marked on the equipment. When using in pulling operations, ensure that the pulling force does not exceed the specified limits.

- Use only the specified operating lever that comes with the machine. Never extend the operating lever with a tube or other accessories, as this may cause damage or cause the safety pin to break due to excessive stress.

- Never attempt to operate the lifting and lowering handles simultaneously.

For applications of transport of people, use only machines designed or modified specifically for this purpose and follow the detailed instructions from the supplier. Additional safety equipment may be required.

Inspection and Maintenance in Use

Follow the manufacturer's maintenance instructions and incorporate them into an on-site maintenance plan, taking into account site- or environment-specific factors. Insufficient lubrication can cause slow operation or total machine failure. Always ensure the machine is well lubricated – there is no problem with over-lubricating a wire rope traction winch.

It is crucial to regularly inspect the machine and the cable. If any of the following faults are observed

Reviews

There are no reviews yet.