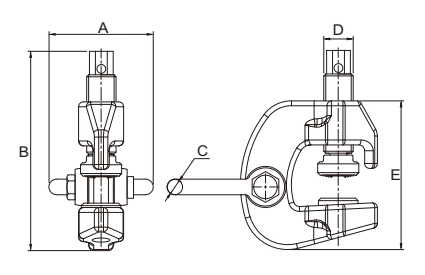

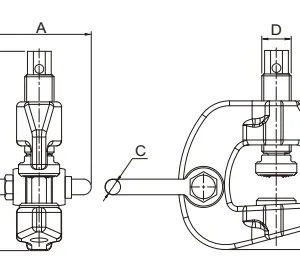

SCC Cam Clamp with Spindle

Product Number: 1608

O Camshaft Clamp with Spindle It is ideal for lifting, suspending, pulling laterally, and turning steel plates. This clamp is commonly used in civil engineering, construction, steel manufacturing, shipbuilding, and the steel plate processing industry.

Versatility

- Versatile Use: Designed for vertical and horizontal lifting and handling of various steel structures.

- Multipurpose: The clamp can be installed upside down for use as a temporary suspension point.

- No Minimum Workload: Suitable for various lifting operations, dispensing with minimum load requirements.

- High Fixing Strength: The mobile clamp in the groove ensures a firm fixation of the steel plate.

- Safety Mechanism: Equipped with a spindle safety mechanism to prevent slipping during lifting.

- Design Leve: Easy to handle, reducing fatigue even during prolonged use.

- Durability: Built from high-quality forged steel for greater strength and durability.

- Fácil Manutenção: Has easily replaceable parts to minimize downtime.

- Material Hardness: Cams and pivots are designed to support materials with hardness up to 30 HRC (Rockwell C).

Important Usage Guidelines

- Balanced Use: Always use two or more clamps in a balanced way to ensure load stability.

- Correct Insertion of the Claws: Make sure the load is fully inserted to the bottom of the claws.

- Restrictions:

- Do not use clamps for single-point lifting.

- Avoid lifting multiple objects at once.

- Not suitable for extracting sheet piles or for vertical lifting of sheets.

- Do not use in strong wind conditions that may pose a danger.

- This clamp is not suitable for use with hydraulic forklifts.

- Before use, make sure the contact surfaces are clean and free of oil, paint, scale, rust, etc.

Especificações do Produto

| Item Code | Capacity (t) | Claw Opening (mm) | Dimensions (mm) | Net Weight (kg) | Product Code |

|---|---|---|---|---|---|

| SCC050 | 0.5 | 0-28 | 52 x 158 x 11 x 18 x 105 | 0.7 | 160800500 |

| SCC075 | 0.75 | 0-22 | 62 x 185 x 13 x 30 x 135 | 2.7 | 160800750 |

| SCC150 | 1.5 | 0-32 | 77 x 215 x 16 x 30 x 155 | 4 | 160801500 |

| SCC300 | 3 | 0-50 | 88 x 270 x 19 x 36 x 191 | 6 | 160803000 |

| SCC600 | 6 | 0-75 | 153 x 290 x 32 x 45 x 255 | 18 | 160806000 |

Related Products

- Manual Chain Slab

- Lever Handle Talha

- Manual Movement Cart

- Conjunto de Polias Pesadas

Safe Use of Lifting Clamps

Always:

- Store and handle the lifting clamps with care.

- Inspect the beam clamps and accessories before each use and before storage.

- Make sure the clamp is securely positioned on the steel plate.

- Make sure the clamp is positioned directly above the center of gravity of the load.

- Press or fully lock the clamp before lifting.

- Always check if the steel plate is properly supported before releasing the clamp.

Never:

- Do not use this clamp unless it is specifically designed for hard or polished steel sheets.

- Never place any filler between the steel plate and the clamp jaws.

- Never attempt to lift multiple steel plates simultaneously with a single clamp.

- Do not alternate between vertical and horizontal elevation unless the clamp is specifically designed for it.

- Do not use vertical lifting clamps at an angle.

- Do not force the lifting hook into the shackle eye.

Choosing the Right Suspension Clamp

The lifting clamps are available in various capacities and models, using mechanisms such as levers, cams, rollers, or screws to provide a secure grip on the plates. When selecting the appropriate suspension clamp, consider the following factors:

- Type of Clamp: Lever, cam, roller, or screw action.

- Capacity and Plate Thickness: Make sure the clamp supports the load and the thickness of the plate.

- Lanyard or Chain: Determine if a sling or chain is necessary for lifting.

Notas Importantes:

- Certain clamp models, particularly those with movable cam jaws and a spring-preloaded initial clamp, have minimum load and plate thickness for safe operation. In the absence of specific guidelines, the load must not be less than 20% of the Safe Working Load (SWL) and the plate thickness must not be less than 20% of the clamp's nominal maximum plate thickness.

- Some clamp models are designed to lift plates from the horizontal to the vertical position and require a sling chain to provide articulation between the clamp and the lifting hook. Be sure to use a sling chain to prevent the weight of the lifting hook from acting directly on the clamp, avoiding it from coming loose.

Storage and Handling of Lifting Clamps

The lifting clamps must be kept clean and dry, and protected against corrosion. Avoid storing damaged or dirty clamps in the storage area. Avoid drops or careless handling of the clamps.

Safe Use of Lifting Clamps

- Never use damaged or defective lifting clamps or accessories.

- Avoid using clamps with loads below 20% of the SWL or thicknesses below 20% of the maximum capacity, unless the manufacturer's guidelines specify otherwise.

- Position the clamps correctly over the center of the load. For long plates subject to bending, use two clamps positioned symmetrically in relation to the center of gravity, with a suspension bar or balance beam. Make sure that no clamp exceeds its SWL.

- Make sure the clamps are firmly attached to the board.

- Do not place shims between the plate and the jaws and never try to lift multiple plates with a single clamp.

- Do not use angled tweezers on the edge of the board, nor to lift from vertical to horizontal, unless they are designed for that.

- When using tweezers that rely on friction materials to hold the plate, avoid contaminating the jaws with oil or other contaminants.

Inspection and Maintenance During Use

The lifting clamps must be cleaned regularly and the moving parts must be lubricated at appropriate intervals, unless otherwise specified by the manufacturer.

For calipers with jaws coated with friction materials, avoid contact of the lubricant with the friction materials. Periodically inspect the calipers for signs of wear or damage and consult a qualified professional if you observe the following failures:

- Wear, damage, or deformation of the fixed and movable jaws

- Cracks or openings in the structure.

- Pins, screws, etc., worn or bent.

- Deterioration of friction materials.

- Damage to the locking levers or fixing threads.

- Corrosion or identification erased.

WARNING: Never file or cut the teeth of the jaws unless explicitly authorized by the manufacturer.

hqlifting For hqlifting, safety and quality are fundamental in all operations with lifting clamps. Preventive maintenance and correct use are essential to avoid accidents and increase the lifespan of your lifting equipment.

Reviews

There are no reviews yet.